Caution – Bard HAC481-BD040 User Manual

Page 7

Manual 2100-346

Page 5

SWEAT STYLE TUBING CONNECTIONS: SWEAT

INDOOR UNIT and SWEAT OUTDOOR UNIT

Use only refrigeration grade (dehydrated and sealed) copper

tubing. Care must be taken to insure that the tubing is kept

clean and dry before and during installation. Do not remove

the plugs from the tubing ends, coil connections or base

valves until the connection is ready to be brazed.

The suction line must be insulated with a minimum of 3/8”

Armaflex or equivalent before cutting and making

connections.

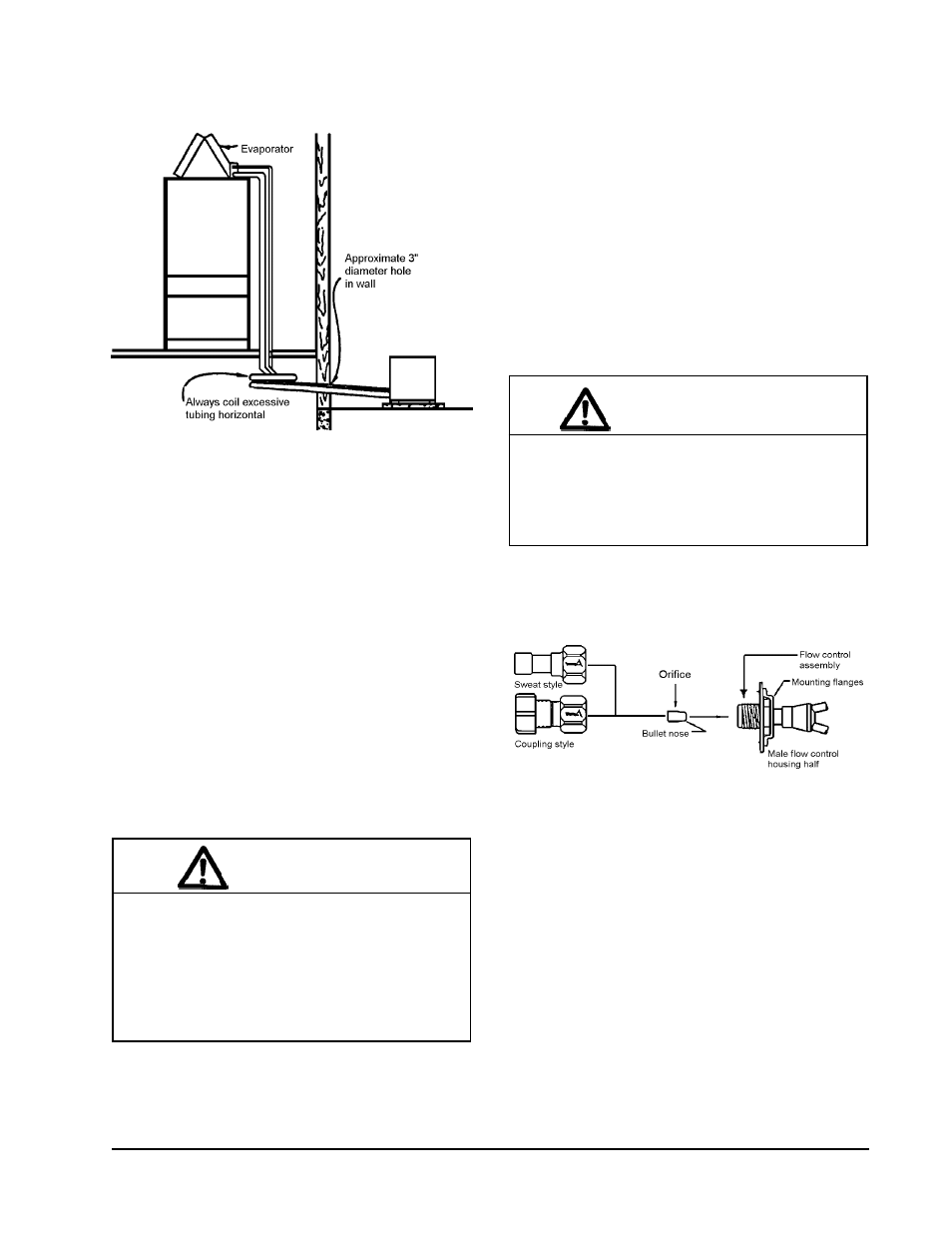

1. Being careful not to kink, route both the suction line

and liquid line between the indoor unit and outdoor

unit. Use a tubing bender to make any necessary bends

in tubing. When necessary to bend the insulated tube

suction line, cut the insulation around its circumference

at a distance far enough beyond the point of the bend so

as to clear the tubing bender. Slip the insulation back

together and vapor seal the joint with tape. Coil any

excess tubing in a horizontal place with the slope of the

tubing toward the condensing unit. See Figure 3.

NOTE:

Do not braze line to units!

If orifice needs to be

changed, change out orifice first.

If the orifice does not have to be changed, skip the

instructions outlined further in Step 3 and proceed to Step 8.

3. Disassemble Flow Control Assembly by turning body

hex.

4. If existing orifice has not dropped out of the body when

disassembled, remove by using a pin or paper clip.

Discard this original orifice.

5. Insert proper sized orifice fully into the flow control

body with rounded “bullet” nose towards the unit as

shown in Figure 4. Insure the orifice stays inserted in

body before connecting mating half. See chart in the

outdoor unit installation instructions for proper size.

6. Thread assembly halves together by hand to insure

proper mating of threads and tighten until bodies

“bottom” or a definite resistance is felt.

7. Using a marker pen or ink pen, mark a line lengthwise

from the union nut to the bulkhead. Then tighten an

additional 1/6 turn (or 1 hex flat). The misalignment of

the line will show the amount the assembly has been

tightened. This final 1/6 turn is necessary to insure the

formation of the leakproof joint.

8. Wrap a wet rag around the copper stub before brazing.

9. Flux the copper tube and insert into the stub. Braze the

joint using an alloy of silver or copper and phosphorus

with a melting temperature above 1,100° F for copper

to copper joints. The phosphorus will act as a flux,

therefore, no flux will be required.

FIGURE 3

INSTALLING REFRIGERANT TUBING

FIGURE 4

FLOW CONTROL ASSEMBLY

FIELD ORIFICE REPLACEMENT INSTRUCTIONS

pp5

CAUTION

1. Be careful not to tear the insulation when

pushing it through hole in masonry or frame

walls. 2. When sealing the tube opening in

house wall, use a soft material to prevent tube

damage and vibration transmission. 3. Avoid

excessive bending in any one place to avoid

kinking.

CAUTION

Be sure there is no dirt introduced into the flow

control - orifice assembly. Be sure to install the

orifice with the bullet nose pointing in the proper

direction as shown in Figure 4. Failure to do so

will result in improper operation.

2. The tubing ends should be cut square. Make sure it is

round and free of burrs at the connecting ends. Clean

the tubing to prevent contaminants from entering the

system.

pp5