Bard HAC481-BD040 User Manual

Page 14

Manual 2100-346

Page 12

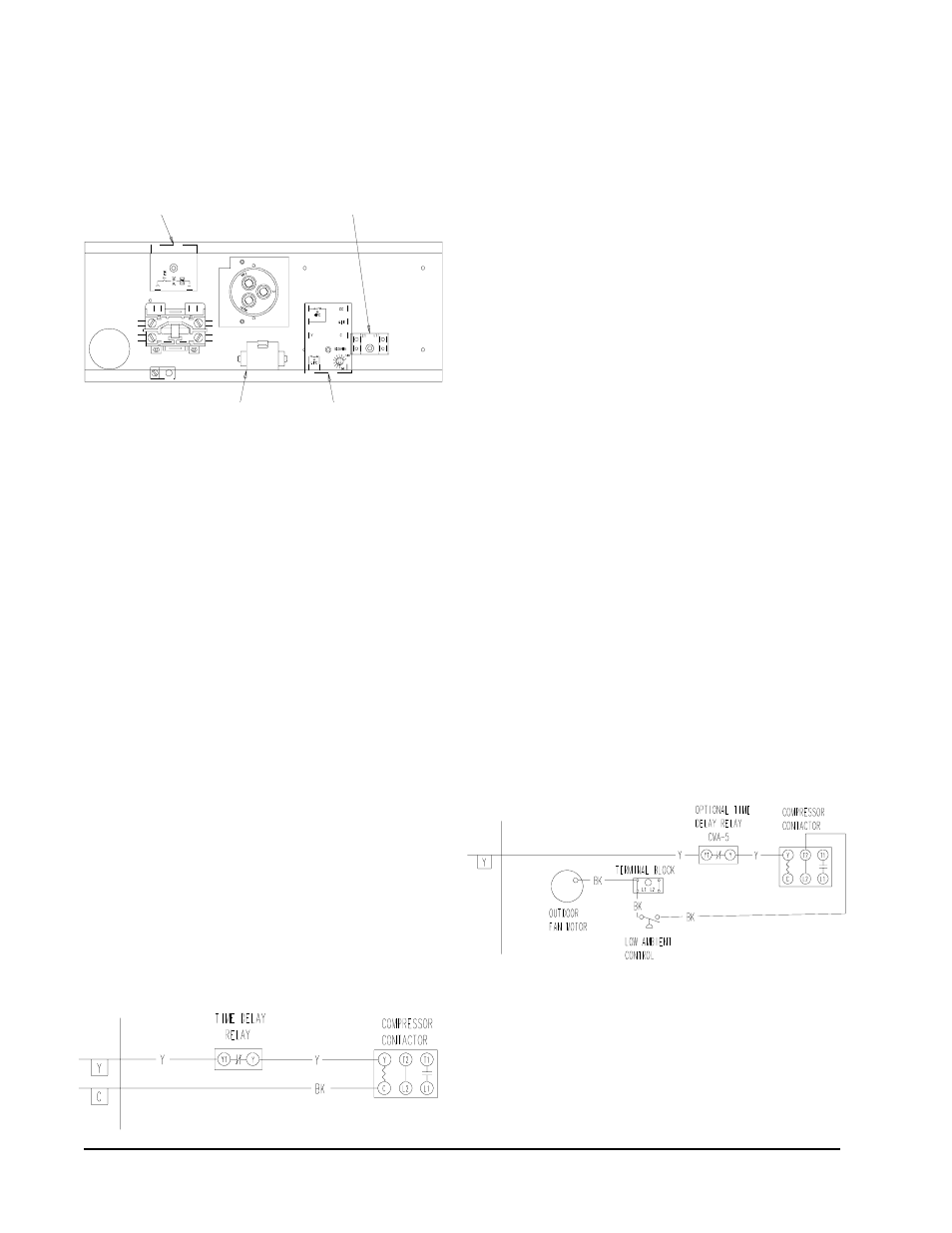

FIGURE 5

COMPONENT MOUNTING LOCATION

OPTIONAL CONTROLS

MIS-1302

INSTALLATION INSTRUCTIONS — CMA-5

Disconnect all power to the unit. Remove control panel

cover.

1. Mount compressor TDR in position shown in Figure 5

with screw provided.

2. Disconnect yellow low voltage (Y) wire at the

compressor contactor coil and reconnect to the Y1 or #3

terminal of the TDR.

3. Connect yellow wire from terminal (Y) of the TDR to

the (Y) terminal of the compressor contactor coil. This

is the terminal that the wire was removed from in

Step 2.

4. Recheck wiring. Refer to Figure 9. Energize unit.

Compressor should start. Remove power and reapply.

Compressor should not start until the 5 minute time

delay has expired.

5. Apply “This unit equipped with CMA-5 control

module” label to inside of the inner control panel cover

above wiring diagram.

6. Replace all panels and covers. This completes

installation.

INSTALLATION INSTRUCTIONS — CMA-6

Disconnect all power to unit. Remove control panel inner

and outer cover.

1. Mount terminal block in position shown in Figure 5.

2. Disconnect black high voltage outdoor motor lead from

compressor contactor and reconnect to terminal block.

3. Route low ambient control wires up through the

bushing in the bottom of the control panel. Connect the

low ambient control wires between the terminal block

and T2 of the compressor contactor.

4. Remove service port cap on discharge line. Install the

low ambient control on the discharge line with the flare

tee adapter that is brazed to the low ambient control.

Check for pressure at the flare tee dill valve after

installation to insure that the dill valve in the unit

service port was depressed by the flare tee connector.

Check for leaks at the flare tee connectors. Replace

service port cap on the flare tee service port and tighten.

5. Recheck wiring. See Figure 10. Check for proper

operation of the unit by energizing in cooling mode.

The condenser fan motor should not run until the

discharge pressure has exceeded 300 PSI. Should the

discharge pressure fall below 200 PSI while running,

the condenser fan motor will de-energize until the head

pressure builds to 300 PSI.

6. Apply “This unit equipped with CMA-6 control

module” label to the inside of the control panel cover

above the wiring diagrams.

7. Replace all panels and covers. This completes

installation.

FIGURE 6

INSTALLATION INSTRUCTIONS

FOR CMA-5 COMPRESSOR TIME DELAY RELAY

MIS-598

FIGURE 7

INSTALLATION INSTRUCTIONS FOR

CMA-6 LOW AMBIENT FAN CYCLING CONTROL

MIS-594

CMA-5 & CMA-13A LOW

AMBIENT FAN CYCLING

CONTROL TERMINAL BLOCK

CMA-5 COMPRESSOR

TIME DELAY RELAY

SK109 LOW VOLTAGE

START KIT

CMA-10A & CMA-13A

COMPRESSOR

CONTROL