Multiquip 382V User Manual

Page 8

PAGE 8 — MODEL 314/382 FLEXIBLE SHAFT — PARTS & OPERATION MANUAL — REV. #0 (04/08/02)

MAINTENANCE

Daily Inspection

1. Following daily use remove any dirt and concrete from the

shaft, motor and head.

2. Inspect the unit for any damage to any of the three compo-

nents and have repaired before further use. Refer to the

respective instruction bulletins for repair of the power unit

and head.

3. Inspect the casing for any cuts or holes through the covering,

loose ferrules, or a permanent kink in the shaft. If any of these

conditions are found, replace the casing.

100 Hour Maintenance

1. Remove the shaft form the motor.

2. If the shaft is equipped with a quick disconnect coupling,

unscrew it from the casing ferrule. Threads are right

handed.

3. Unscrew the vibrator head from the shaft casing. Threads

are left handed. Heat should be used to loosen the

anaerobic sealant in the threads.

4. Pull the core out of the casing, wiping the grease off as it is

pulled form the casing.

5. Inspect the core for broken wires, a permanent set, or other

damage such as an area that shows high wear of having run

overheated. Replace with a new core if these conditions

exist.

6. Use the core to push a cleaning patch through the casing to

remove the old grease and any foreign matter.

7. Thoroughly clean the core if it is being reused.

8. Relube the core. Coat it with

DuBois "TPG"

lubricant or a

good grade of ball bearing grease. Only a light coating is

needed. CAUTION: DO NOT

"pack"

the shaft assembly

with grease. Excessive lubrication will cause overheating.

9. Reassemble using the reverse procedure.

10. When connecting the head to the casing, clean the mating

threads with an anaerobic sealant primer and allow to dry for

several minutes. Apply a ring of anaerobic sealant to the

middle of the casing ferrule threads. Screw the head tightly

to the casing and wait for one hour before using.

Connecting the QD Coupling to the Core.

1. Slide the core out of the casing far enough to thread the

spindle into the core fitting and tighten. If the connection is not

tight, the torque of the motor plus the load of the head will jam

the two fittings together, making it extremely hard to loosen

them for disassembly.

2. Thread the Q.D. coupling into the casing ferrule and tighten.

3. To connect the shaft assembly and Q.D. coupling to the

vibrator motor, pull up on the lock pin a d slide the shaft into

the end bell. Release the lock pin and give the shaft assembly

a twist to make certain the lock pin is seated in one of the 3

holes in the shaft coupling.

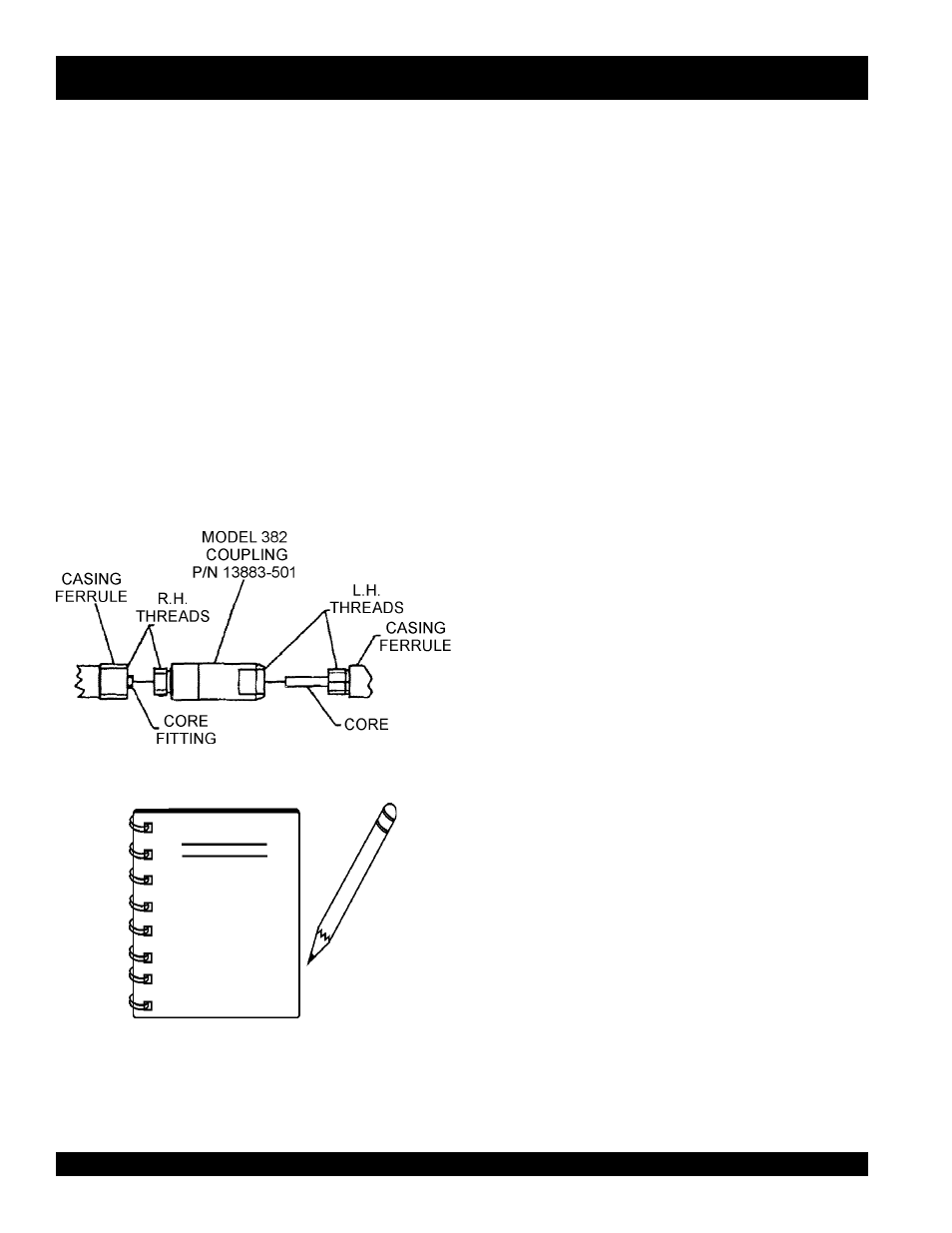

Connecting Two Flexible Shafts (Model 382)

1. Use coupling P/N 13883-501 when joining the two flexible

shafts (Model 382) together.

2. Connect both flexible shafts as shown in Figure 3.

When ordering core or

casing part numbers

use Table 2.

Example: (Model 314)

A complete Core and Casing Assembly

part num-

ber would be 13609. If a 12 foot shaft is desired, select

512. The new complete part number using a 12 ft. shaft

would be 1309-512.

NOTE

VIBRATOR SHAFT MODEL 314/382 — OPERATION/MAINTENANCE

Figure 3. Connecting Two Flexible Shafts