Maintenance – Multiquip CA4HM User Manual

Page 29

CA4HM WALK-BEHIND TROWEL — OPERATION MANUAL — REV. #3 (10/28/10) — PAGE 29

Figure 32. Trowel Arm Adjustment Tool

Changing a Blade

We recommend that

all the blades be changed at the

same

time

. The machine may wobble or bounce if only some of the

blades are changed at one time.

1. Place the machine on a flat, level surface. Adjust the blade

pitch control to make the blades as flat as possible. Note the

blade orientation on the trowel arm.

1. Remove the two bolts and lock washers that secure the blade

to the trowel arm. Remove the blade.

2. Using a wire brush, scrape all concrete particles and foreign

debris from the trowel arm.

3. Install the new trowel blade onto the trowel arm. Make sure

blade is installed correctly, maintaining the proper orienta-

tion for direction of rotation.

4.

Reinstall

the two bolts and lock washers that secure the

blade to the trowel arm. Tighten both bolts securely.

5. Repeat steps 1 - 4 for all remaining blades.

Hand Clutch Adjustment

This trowel is equipped with a hand-operated clutch that is a belt-

tightener type clutch. It operates by removing

slack

in the V-belt

which then transmits power from the engine to the gearbox.

There are two reasons to adjust the hand clutch: 1) operator

comfort; 2) initial belt stretch and break-in.

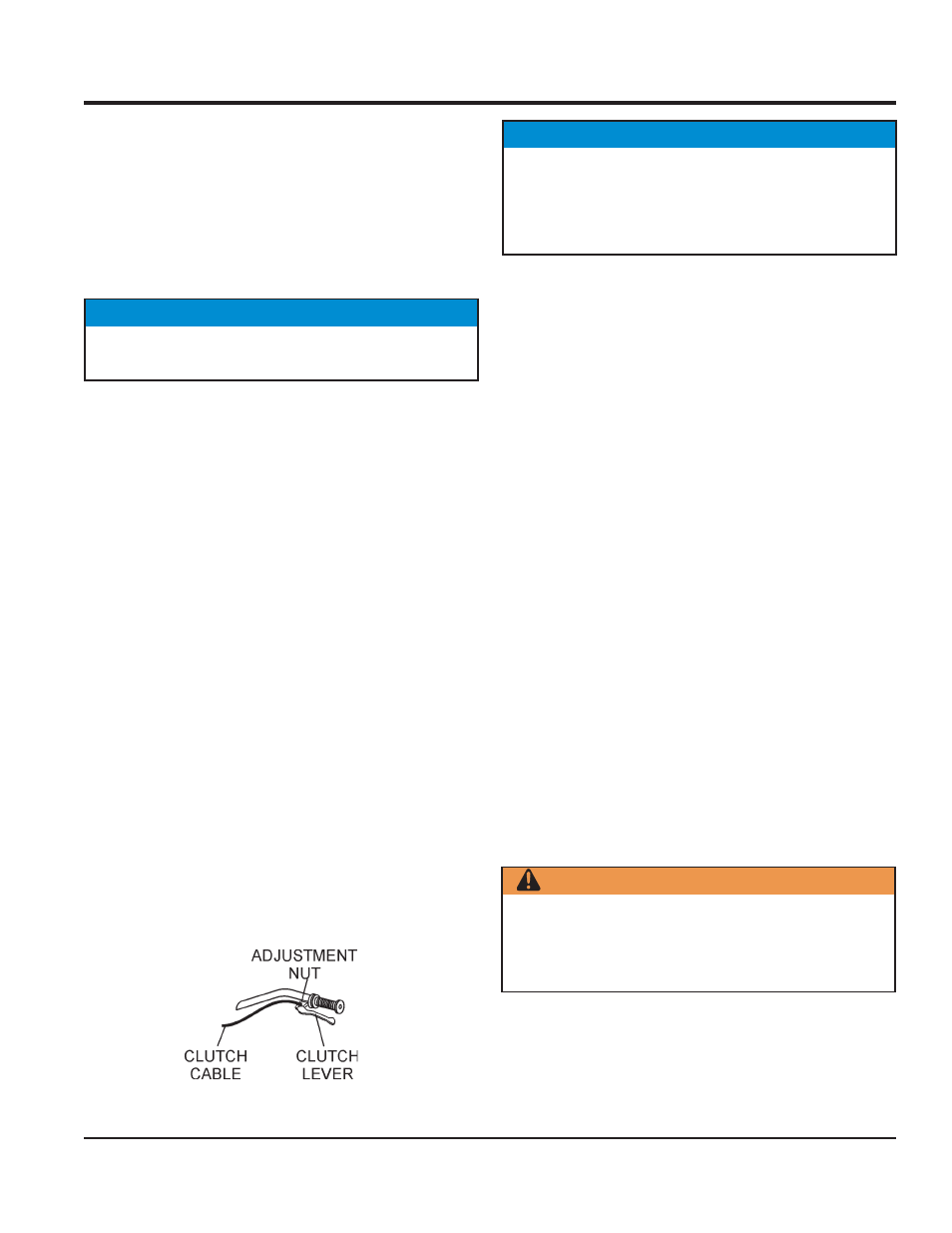

The easiest and most simple adjustment is to adjust the clutch

cable housing using the adjustment nut (Figure 32) located on the

clutch lever. Rotating the nut provides either more or less

(depending upon the direction of rotation) clutch engagement.

Hand Clutch Disengagement

1. Start the trowel as outlined in the "

Initial Start-up

" section in

this manual. Move the throttle lever so that the engine is

running about 1/4 to 1/3 of full speed.

2. Grip the trowel handle firmly and carefully engage the clutch

by squeezing the clutch lever toward the handle with your left

hand. After the trowel is stabilized and you feel comfortable

with its operation, use your right hand to adjust the housing

adjustment nut.

3. Rotating the nut so that it backs out of the lever housing

increases the engagement and also the squeezing force

required to keep it engaged.

Too much squeezing force may cause premature hand

fatigue. Too little squeezing force may cause belt slippage

and premature belt wear. Each operator should experiment

with the adjustment to get the optimum combination of

squeeze force and belt grip.

4. After initial break-in (approximately 8 hours) the above

procedure should be repeated to attain optimum operator

comfort and belt wear.

5. After considerable belt wear, the adjustments mentioned

above may have a little or no effect on clutch engagement. If

this is the case, the belt should be replaced.

MAINTENANCE

Before removing the blades, please note the orientation

of the blade on the trowel arm.

NOTICE

Check the manual clutch occasionally for proper operation.

Checking operation of the manual clutch at the beginning of

operation and periodically serves as a safety check verifica-

tion.

NOTICE

NEVER attempt to override the manual clutch by using

tape or other means to hold down the clutch lever. Doing so

may cause SEVERE INJURY.

WARNING