Str36sp-series— maintenance – Multiquip STR36SP User Manual

Page 31

STR36SP- SERIES • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #1 (09/16/11) — PAGE 31

How It Works (Figure 25)

Condition A:

Engine Idling

Drive Pulley: Small

Driven Pulley: Large

Belt: Loose and Stationary

Condition B:

Engine Accelerating

Drive Pulley: Small But Increasing

Driven Pulley: Large But Decreasing

Belt: Approaching Tightness

Condition C:

Engine At High Speed

Drive Pulley: Large

Driven Pulley: Small

Belt: Tight

The torque-sensitive pulley (Figure 26) utilizes a spring and cam.

Peak performance results from proper interaction between the driven

pulley spring and the ramp angle of the cam bracket.

DRIVEN PULLEY

FIXED FACE

MOVEABLE

FACE

CAM

BRACKET

SPRING

Figure 26. Pulley Spring and Cam Bracket

STR36SP-SERIES— MAINTENANCE

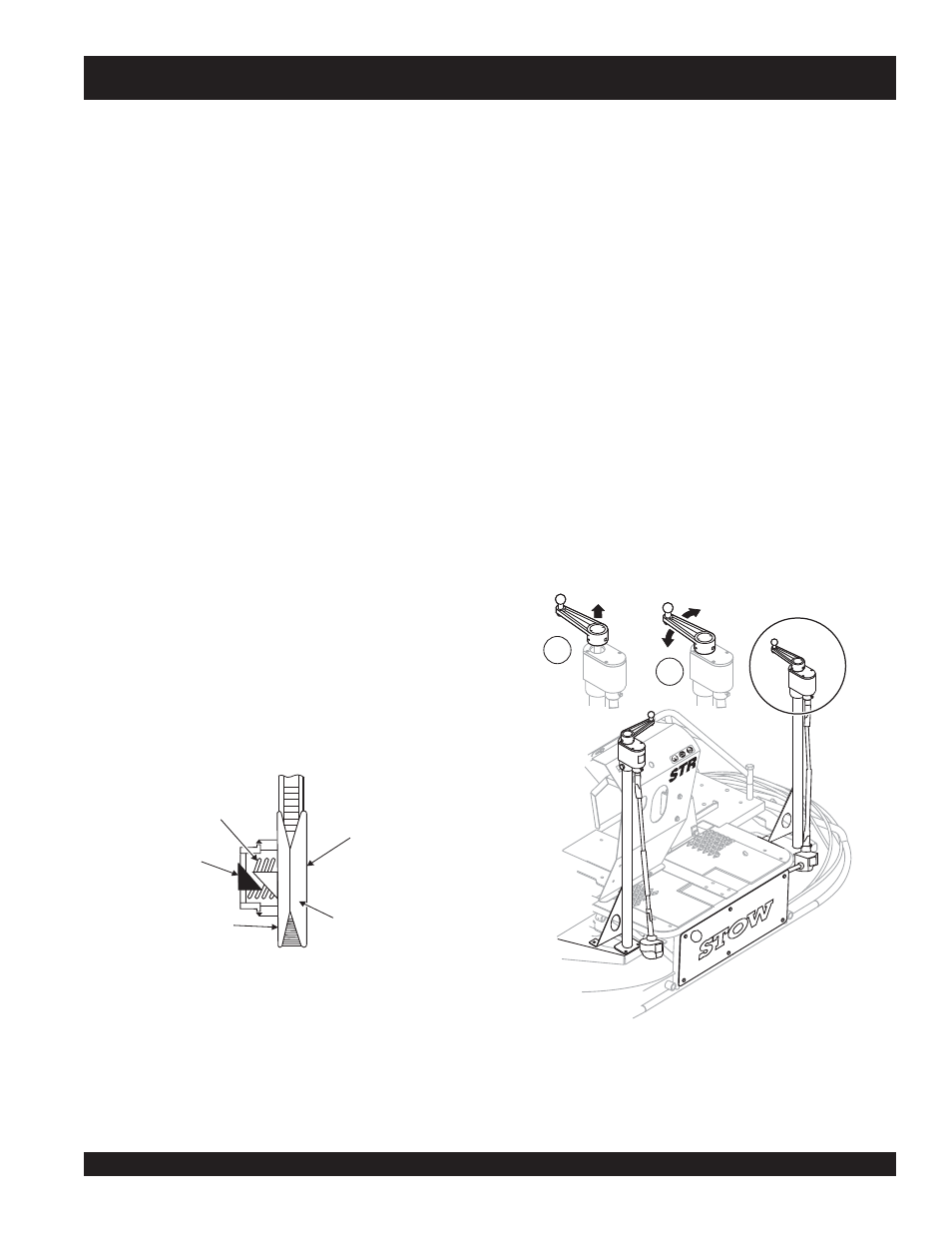

Trowels equipped with optional Twin Pitch

TM

Controls may need

to have blade pitch between the two sets of blades "syncronized".

If the blades need to be syncronized this is easily accomplished

by performing the following. Refer to Figure 27.

Blade Pitch

Sometimes it may be necessary to match blade pitch between

the two sets of blades. There are some signs that this may be

necessary. For example, the differences in pitch could cause a

noticeable difference in finish quality between the two sets of

blades. Or, the difference in blade pitch could make the machine

difficult to control. This is due to the surface area in contact with

the concrete (the blade set with the greater contact area tends to

stick to the concrete more).

This clutch system provides a high pulley ratio (a low gear- so to

speak) to start out and a low pulley ratio (a high gear- so to

speak) for a high speed operation, with infinite variation between

the two.

This means that it will not be necessary to give

full throttle

in

order to "break the blades/pans loose". The machine can slowly

be brought up to speed.

Clutch

Figure 27. Pitch Towers

Matching Blade Pitch for Both Sets of Blades

A

Twin Pitch

TM

disengaged (one side)

B

Operating Position

A

B

1.

Lift the pitch adjustment handle on either side. Once lifted,

that side is now disconnected from the Twin Pitch

TM

system.

2.

Adjust to match the opposite side.

3.

When adjusted, lower the handle to Twin Pitch

TM

operating

position.