Wrs-5200 — maintenance and adjustment procedures – Multiquip WRS5200 (CHINA) User Manual

Page 27

WRS 5200 RIDE-ON ROLLER SCREED — PARTS MANUAL— REV. 1# (12/14/01) — PAGE 27

WRS-5200 — MAINTENANCE AND ADJUSTMENT PROCEDURES

D.

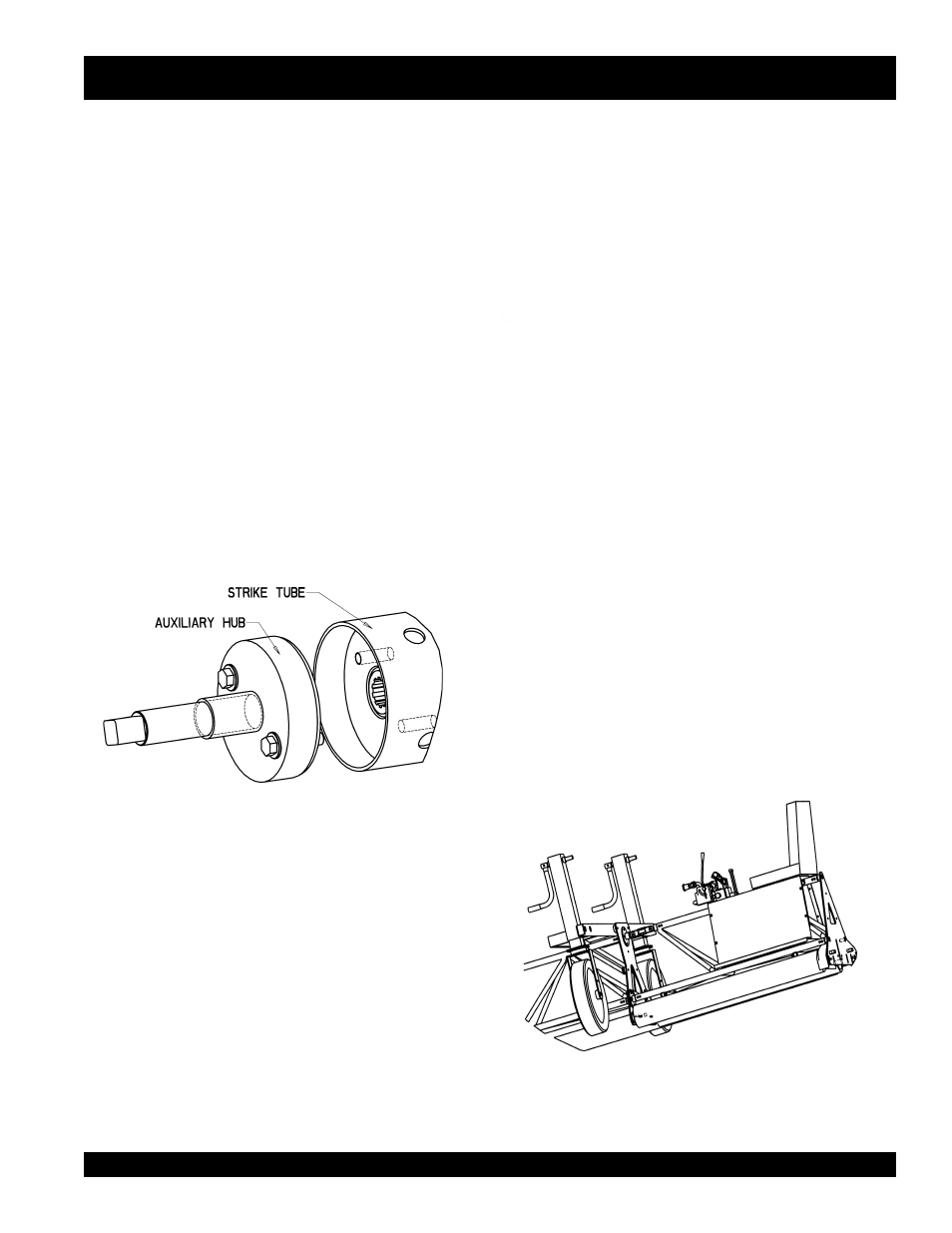

STRAIGHTNESS OF STRIKE TUBES

Should strike tubes begin turning unevenly, contact your lo-

cal Multiquip representative for information on strike tube

straightening procedures.

To determine if a strike tube is turning uneven, place a 2 x 4

stud on the ground in the center of the strike tube as it sits

on the machine. Slide it close to the strike tube. Take the

strike tube motor off the end. Spin the strike tube by hand. If

a gap of over 1/8 inch shows up, contact your representa-

tive.

E.

AUXILIARY HUB

An auxiliary hub, shown in Figure 16, for use with different

strike tubes is provided. Using the hub provides additional

combinations of roller screed lengths. Two ½ x 2-1/4 bolts

are provided for the purpose of bolting the hub to the strike

tube end.

Figure 16. Auxiliary Hub

Wiper bars should be adjusted to approximately 1/8” dis-

tance from the strike tube. The turnbuckle in the top pipe of

the 5’ section is also an adjustment for the wiper bar. This

adjustment can be used when the end of the wiper bar is too

close to the strike tube. IMPORTANT: Never let anything

rub grooves into the strike tube( i.e. wiper bars, concrete

forms, bolts, etc.) because those grooves in the strike tube

will be transferred into the concrete.

H.

STRIKE TUBE ADJUSTMENT NUT

The strike tube adjustment nut, shown in Figure 8, should

be adjusted so the inner edge of the strike tube next to the

middle bracket is spaced at about 1/16 to 1/8”. Note: The

strike tube will bottom out on the splined shaft when 1/16” is

left and further adjustment will bend the outer plate.

I.

SPLINED SHAFT SET SCREWS

Each roller screed comes with two middle brackets as shown

in Figure 9. Bearings mounted on the middle bracket hold

the splined shaft. The set screws in the bearings should be

checked for tightness occasionally.

J. REVERSING END CASTER BRACKETS

Figure 17 illustrates how end caster brackets can be re-

versed. This allows the roller screed to fit into areas close to

walls and columns.

Figure 17. Reversing Caster Brackets

F.

CHANGING THE HYDRAULIC FILTER

Usually the hydraulic filter and oil will be changed at the

same time. If not, creating a back suction on the hydraulic

tank will stop the flow of hydraulic oil when changing the

filters.

G.

SCRAPER AND WIPER BAR ADJUSTMENT

Scraper bars should be adjusted to approximately 1/8” dis-

tance from the drive tubes.