Ar-13h ride-on roller — roller components – Multiquip AR13H User Manual

Page 20

PAGE 20 — AR-13H RIDE-ON TANDEM DRUM ROLLER — OPERATION & PARTS MANUAL — REV. #15 (09/15/11)

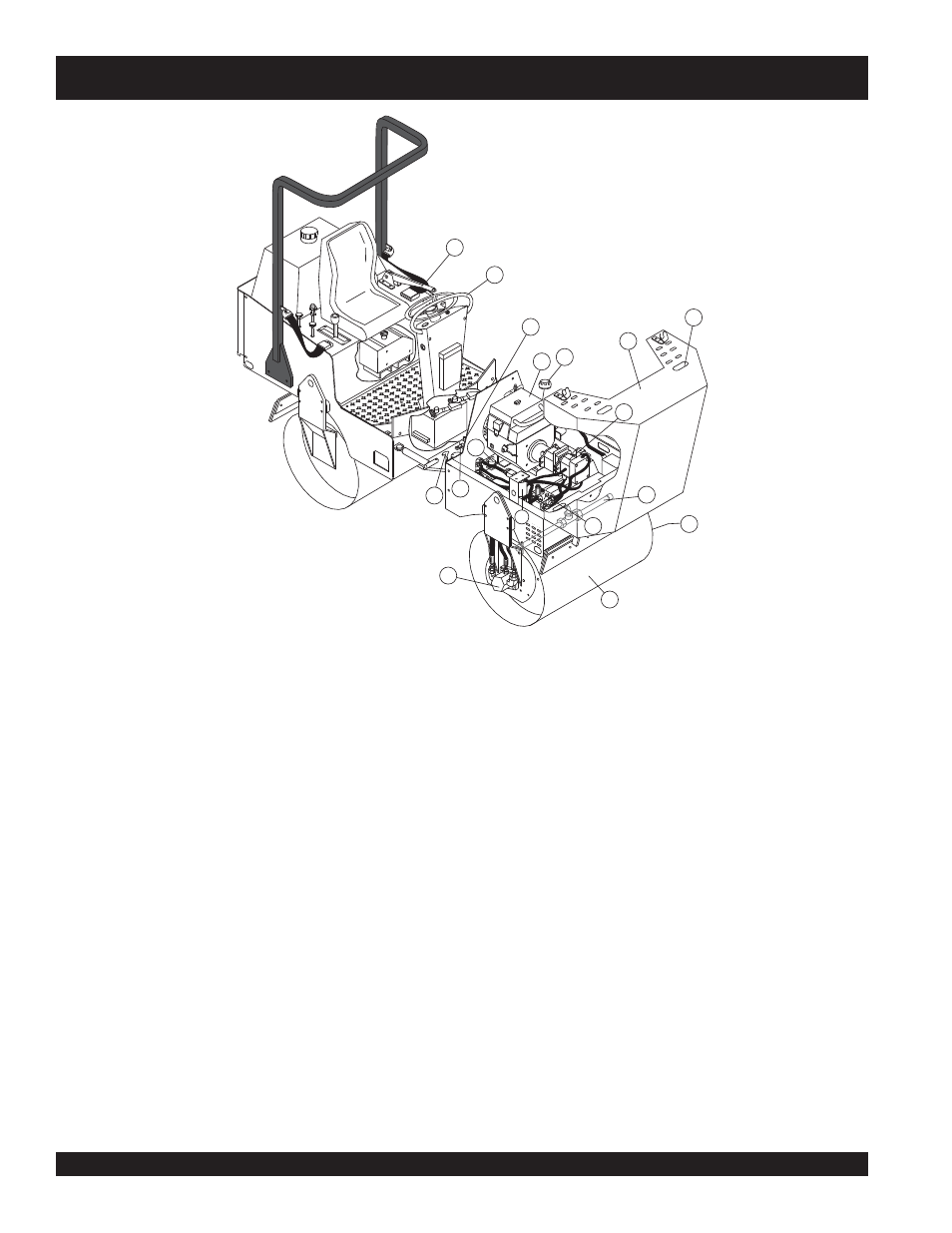

AR-13H RIDE-ON ROLLER — ROLLER COMPONENTS

Figure 5 shows the location of additional components for the

AR-13H compaction roller. The function of each component or

control is described below:

26. Front Sprinkler System – A gravity feed spray bar is

provided for the wetting the roll for asphalt pavement.

27. Hydraulic Manifold – Aluminum block that controls the

flow of hydraulic pressure to the various hydraulic motors

and other components required to control the roller.

28. Hydraulic Oil Filter – Filters return oil from the front

and rear hydrostatic motors.

29. Accessory Relay – Provides the +12VDC necessary

to run the roller's electrical accessories.

30. Hydraulic Pump – This unit incorporates an axial

variable displacement hydraulic piston pump.

31. Front Ride-on Tandem Drum Roller – This roller is a

30 inch wide

steel drum

with beveled edges. The

beveled edges help prevent asphalt marring.

32. Hydraulic Motor – This hydraulic motor controls the

rotation of the vibratory system.

33. Bunjee Latch – Pull this rubber latch upward and back

to gain access to the engine/pump compartment. There

is one rubber latch located on each side of the unit.

Figure 5. Roller Components 2

34. Steering Cylinder – Controls direction of roller.

35. Engine – This unit incorporates a HONDA GX-610, air

cooled engine rated at 18 hp at 3,500 rpm.

36. Hydraulic Fluid Filler Port – Remove this cap to add

hydraulic fluid. Fill with type ISO 46 anti-wear hydraulic

fluid.

37. Compartment Hood – Houses the engine, hydraulic

manifold, accessory relay, hydraulic oil filter, hoses, and

hydraulic pump. To lift the compartment hood, release

the rubber bunjee latches located on each side of the

hood.

38. Compartment Hood Lift Point – Place hand here then

lift upwards to lift compartment hood.

39. Hydraulic Motor – This hydraulic motor drives the roller

during operation.

40. Rear Drum Zerk Grease Fitting – Grease this fitting

bi-weekly. See maintenance section of this manual.

41. Articulation Zerk Grease Fitting – Grease this fitting

once a year. See maintenance section of this manual.

42. Hand Rail – Grab hold of this hand rail when lifting

yourself onto the operator's platform.

31

28

32

39

27

26

30

33 34

29

35

37

36

38

42

40

41