Inspection – Multiquip MTR40SF User Manual

Page 14

page 14 — MTX40sf RaMMeR • opeRaTion and paRTs Manual — Rev. #0 (11/28/12)

inspeCtiOn

This section is intended to assist the operator with the

inspection of the rammer. It is extremely important that

this section be read carefully before attempting to operate

the rammer.

do noT use your rammer until this section is thoroughly

understood.

Check all nuts, bolts fasteners for tightness. Retighten

as necessary.

Clean any dirt from the recoil starter and engine cooling

fins. Wipe the entire rammer clean before operating.

Replace any missing or damaged Safety Operation

decals. It is extremely important that this section be read

carefully before attempting to operate the rammer.

do

noT use your rammer until this section is thoroughly

understood.

prior to operation

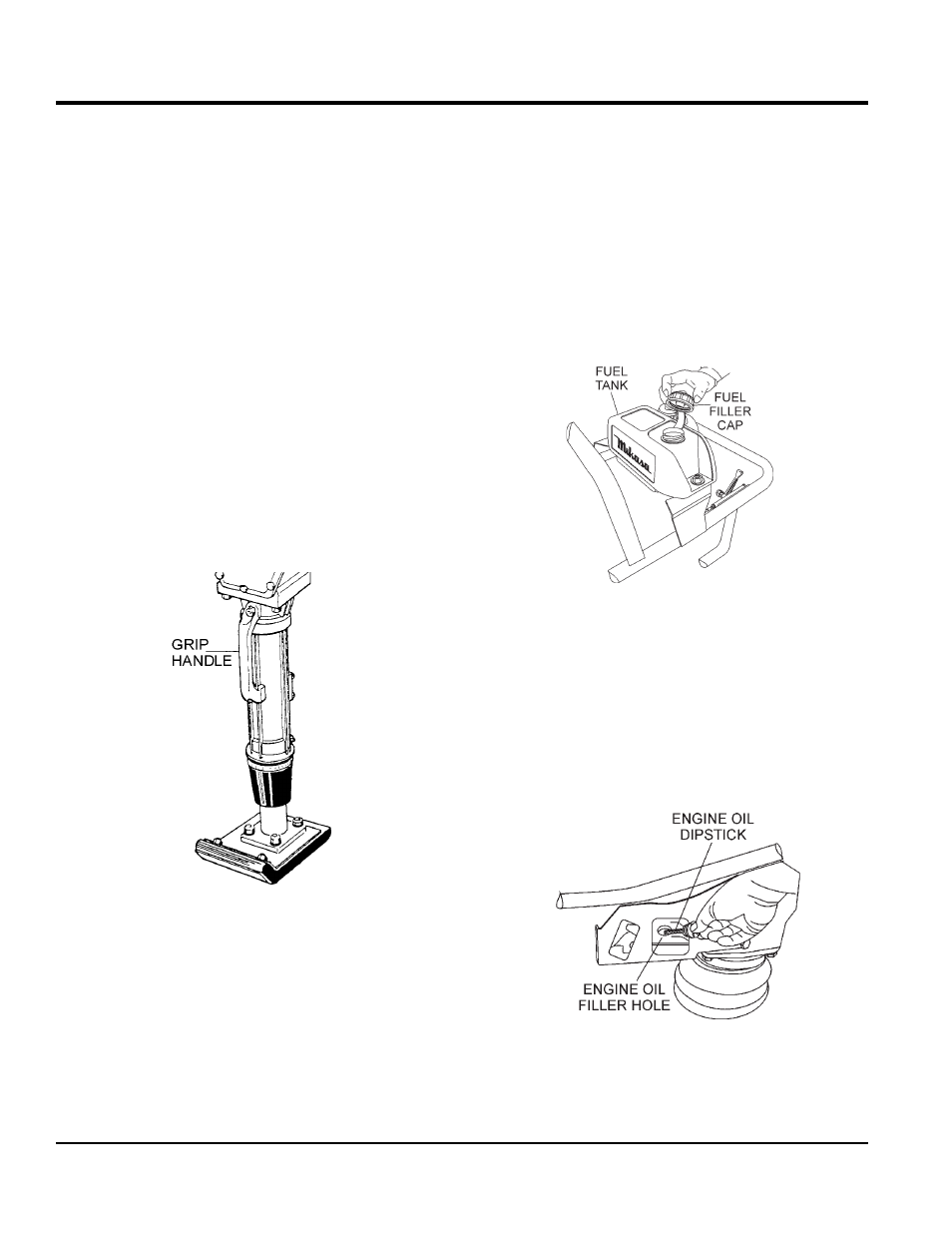

1. When transporting the rammer, carry it by the grip

handle located on the body (Figure 3).

Figure 3. Grip Handle

Main spring and Crankcase lubrication

1. There are 2 grease fittings (Figure 18) that require

lubrication of the main springs. Lubricate these fittings

as outlined in the maintenance section of this manual.

2. There are 2 grease fittings (Figure 19) that require

lubrication of the crankcase. Lubricate these fittings as

outlined in the maintenance section of this manual.to

replenish it often (Figure 5).

fuel

1. This rammer is equipped with a two-cycled gasoline

engine. Use only unleaded gasoline. High test ethyl

gasoline is not recommended.

2. If fuel is low, remove the fuel filler cap (Figure 4) and

fill with onlyunleaded gasoline. Motor fuels are highly

flammable and can be dangerous if mishandled.

do

noT smoke while refueling. do noT attempt to refuel

the rammer if the engine is hot or running.

Figure 4. Fuel Tank

engine oil Check

1. To check the engine oil level, place the rammer on

secure level ground with the engine stopped.

2. Remove the filler cap/dipstick from the engine oil filler

hole (Figure 5) and wipe it clean.

Figure 5. Engine Oil Dipstick

3. Insert and remove the dipstick without screwing it into

the filler neck. Check the oil level shown on the dipstick.

PAGE 14 — MTR40SF RAMMER — OPERATION AND PARTS MANUAL —

REV. #5 (11/01/11)

Figure 3. Grip Handle

Prior to Operation

1. When transporting the rammer, carry it by the grip handle

located on the body (Figure 3).

Fuel

1. This rammer is equipped with a two-cycled gasoline engine.

Use only unleaded gasoline. High test ethyl gasoline

is not

recommended.

2. If fuel is low, remove the fuel filler cap (Figure 4) and fill with

only

unleadedgasoline. Motor fuels are highly flammable

and can be dangerous if mishandled.

DO NOT smoke while

refueling.

DO NOT attempt to refuel the rammer if the engine

is

hot! or running.

Figure 4. Fuel Tank

This section is intended to assist the operator with the

inspection

of the

MTR40SF Tamping Rammer. It is extremely important that

this section be

read carefully before attempting to operate the

rammer.

DO NOT use your rammer until this section is thoroughly

understood.

Inspection

Check all nuts, bolts fasteners for tightness. Retighten as

necessary.

Clean any dirt from the recoil starter and engine cooling fins.

Wipe the entire rammer clean before operating.

Replace any missing or damaged Safety Operation decals.

Engine Oil Check

1. To check the engine oil level, place the rammer on secure

level ground with the engine stopped.

2. Remove the filler cap/dipstick from the engine oil filler hole

(Figure 5) and wipe it clean.

Figure 5. Engine Oil Dipstick

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 6), fill to the edge of the oil filler

hole with the recommended oil type (Table 3). Maximum oil

capacity is .079 gallons (0.3 liters).

Main Spring and Crankcase Lubrication

1. There are 2 grease fittings (Figure 18) that require lubrica-

tion of the main springs. Lubricate these fittings as outlined

in the maintenance section of this manual.

2. There are 2 grease fittings (Figure 19) that require lubrica-

tion of the crankcase. Lubricate these fittings as outlined in

the maintenance section of this manual.

INSPECTION

DO NOT attempt to operate the Tamping

Rammer until the Safety, General

Information and Inspection sections of

this manual have been

read and

thoroughly understood.

CAUTION

PAGE 14 — MTR40SF RAMMER — OPERATION AND PARTS MANUAL —

REV. #5 (11/01/11)

Figure 3. Grip Handle

Prior to Operation

1. When transporting the rammer, carry it by the grip handle

located on the body (Figure 3).

Fuel

1. This rammer is equipped with a two-cycled gasoline engine.

Use only unleaded gasoline. High test ethyl gasoline

is not

recommended.

2. If fuel is low, remove the fuel filler cap (Figure 4) and fill with

only

unleaded

gasoline. Motor fuels are

highly flammable

and can be dangerous if mishandled.

DO NOT smoke while

refueling.

DO NOT attempt to refuel the rammer if the engine

is

hot!

or

running

.

Figure 4. Fuel Tank

This section is intended to assist the operator with the

inspection

of the

MTR40SF Tamping Rammer.

It is extremely important that

this section be

read carefully

before attempting to operate the

rammer.

DO NOT use your rammer until this section is thoroughly

understood.

Inspection

Check all nuts, bolts fasteners for tightness. Retighten as

necessary.

Clean any dirt from the recoil starter and engine cooling fins.

Wipe the entire rammer clean before operating.

Replace any missing or damaged Safety Operation decals.

Engine Oil Check

1. To check the engine oil level, place the rammer on secure

level ground with the engine stopped.

2. Remove the filler cap/dipstick from the engine oil filler hole

(Figure 5) and wipe it clean.

Figure 5. Engine Oil Dipstick

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 6), fill to the edge of the oil filler

hole with the recommended oil type (Table 3). Maximum oil

capacity is .079 gallons (0.3 liters).

Main Spring and Crankcase Lubrication

1. There are 2 grease fittings (Figure 18) that require lubrica-

tion of the main springs. Lubricate these fittings as outlined

in the maintenance section of this manual.

2. There are 2 grease fittings (Figure 19) that require lubrica-

tion of the crankcase. Lubricate these fittings as outlined in

the maintenance section of this manual.

INSPECTION

DO NOT attempt to operate the Tamping

Rammer until the Safety, General

Information and Inspection sections of

this manual have been

read and

thoroughly understood

.

CAUTION