Memmert PM 500 Self Drying Vacuumpump (Generation 2003) User Manual

Page 5

disposed of.

Ī Use only original KNF replacement

parts.

Parts and tools required:

½ 1 Service Set (see section 7)

½ Screwdriver blade width 2 mm

½ Phillips screwdriver No. 2

½ Felt-tip pen.

Change the diaphragms and valve pla-

tes/sealings in the following sequence:

a) Preparatory steps

b) Removing pump head

c) Changing diaphragm

d) Changing valve plates/ sealings

e) Refitting pump head

f) Final steps.

̈ The position numbers in the

following text refer to fig. 2.

a.) Preparatory Steps

ᕡ Shut down system (see section 4.2)

including disconnecting the pump

from the power source (pull out

plug of pump).

ᕢ Remove tubing from the inlet and

outlet connectors of the pump.

» On the pneumatic head connec-

tions, loosen one of the union nuts

by hand. Then slightly loosen the

angle-fitting in the pump head by

turning it anticlockwise, so that the

connecting tube can be pulled out

¿ Undo the screws that hold the

fan cover (see fig. 1) and remove

the fan cover from the motor.

b) Removing pump head

(for each head separately)

³ Mark the position of top plate ቢ,

head plate

ባ, intermediate plate

ቤ, and housing ብ relative to each

other with a felt-tip pen. This is to

ensure that the parts will be re-

assembled cor rectly at a later

stage.

· Undo the eight screws ቦ and lift

the pump head off the housing

ብ.

Ī

The solenoid valve of the

drying system remains fitted

in this situation.

c) Changing diaphragm

³ Position the pump so that the dia-

phragm surface is upwards.

· Turn the fan to bring the structured

diaphragm

ቧ to top dead centre.

» Using a small screwdriver, bet-

ween the housing and the outer

edge of the structured diaphragm,

carefully lift the edge of the dia-

phragm lightly upwards at one

point (making sure not to damage

the housing). Now grip the edge of

the diaphragm on opposite sides,

unscrew it by turning anti-clock-

wise.

¿ Take the diaphragm spacer(s) ቨ off

the connecting rod

ቩ and retain

them.

´ Check that all parts are free from

dirt and clean them if necessary.

² Put the diaphragm spacer(s) ቨ

on the thread of the new dia-

phragm.

ᕧ Fit the new structured diaphragm

ቧ: hold the connecting rod ቩ with

one finger, and gently screw in

(clockwise) the structured dia-

phragm with diaphragm spacers.

º Turn the fan until the structured

diaphragm is at the top dead cent-

re. Using a small screwdriver, bet-

ween the housing and the outer

edge of the structured diaphragm,

carefully lift the edge of the dia-

phragm lightly upwards at one

point. Now grip the edge of the dia-

phragm on opposite sides (do not

overstretch the diaphragm!) and

tighten the structured diaphragm

clock-wise.

d) Changing valve plates/sealings

³ Undo the two screws ቪ.

· Separate the head plate ባ with

top plate

ቢ from intermediate

plate

ቤ.

» Remove the valve plates/sealings

ቭ from the intermediate plate.

¿ Check that the valve seats, the

head plate and intermediate plate

are clean. If scratches, distortion,

or corrosion are evident on these

parts they should be replaced.

´ Lay the new valve plates/sealings

ቭ in the recesses in the interme-

diate plate. The valve plates/sea-

lings for suction and pressure sides

are identical, as are upper and

lower sides of the plates/sealings.

e) Refitting pump head

³ Turn the fan to bring the structured

diaphragm

ቧ to medium position.

· Place the intermediate plate ቤ,

with valve plates/sealings

ቭ on

the housing, in the position indica-

ted by the felt-tip pen marking.

» Place the head plate ባ on the

intermediate plate

ቤ in the posi-

tion indicated by the felt-tip pen

marking.

¿ Place top plate ቢ in position

PM 16527-860.3-2.00 e 11/05

4

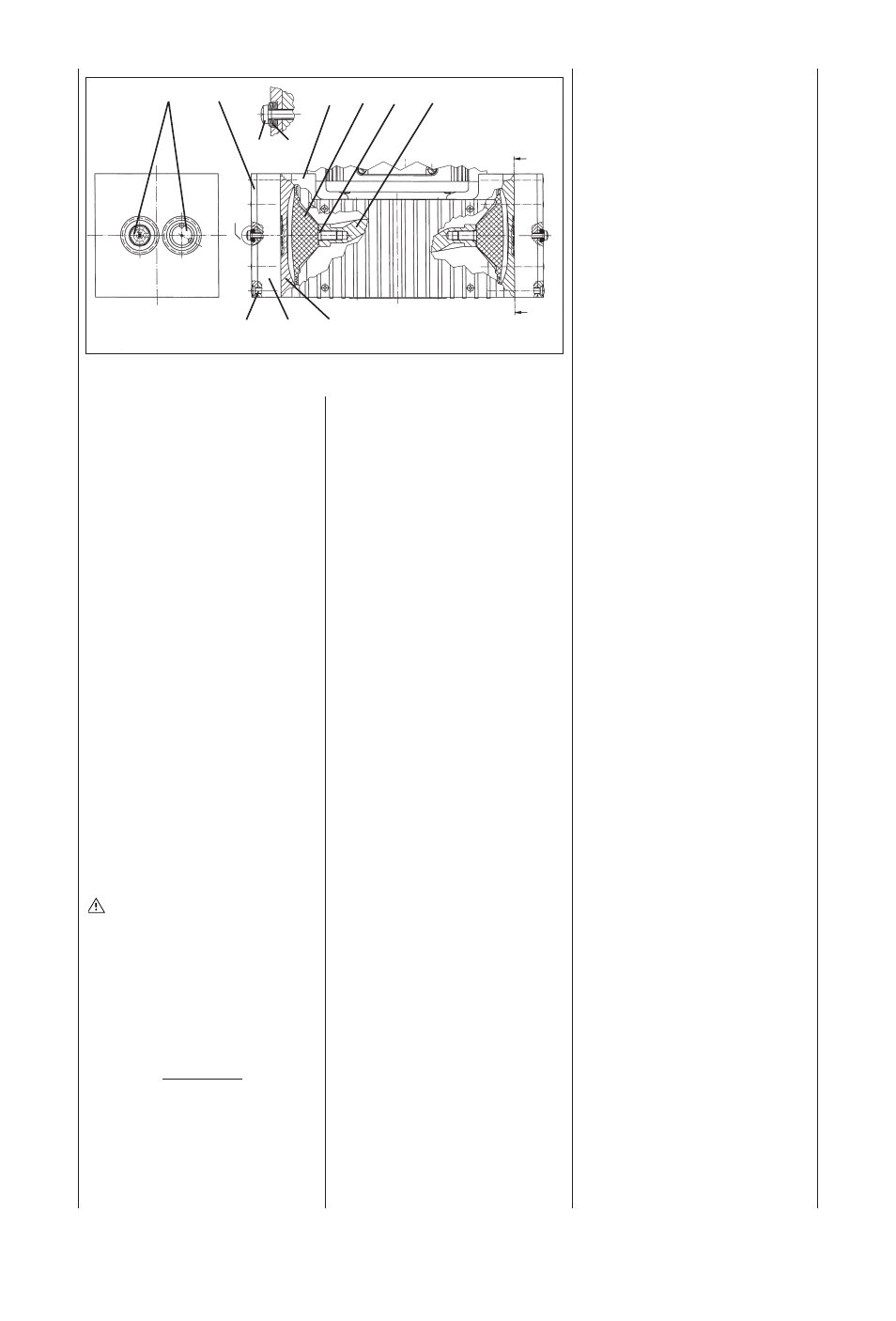

ቦ ባ ቤ

ቭ ቢ

X

X

ብ ቧ ቨ ቩ

ቪ ቫ

Fig. 2: Cross section of pump heads (symbolic)

Specification

Pos Description

ቢ Top plate

ባ Head plate

ቤ Intermediate plate

ብ Housing

ቦ Cross recessed raised counter-

sunk head screw

ቧ Structured diaphragm

ቨ Diaphragm spacers(s)

ቩ Connecting rod

ቪ Cross recessed raised cheese

head screw

ቫ Disk spring

ቭ Valve plate/Sealing