Memmert PM 500 Self Drying Vacuumpump (Generation 2003) User Manual

Page 4

pressure. This also applies when

the pump restarts after the power

has been cut off for a short period.

The components to be connected

to the pump must be designed to

withstand the pneumatic data of

the pumps (see Section 8).

The maximum permissible opera-

ting pressure (1 bar g) must not be

exceeded.

½ To prevent the maximum permis-

sible operating pressure being

exceeded, restriction or control of

the air or gas flow should only be

carried out in the suction line.

½ If restriction or control of the air or

gas flow is made on the pressure

side ensure that the maximum per-

missible operating pressure is not

exceeded.

½ When the pump is at a standstill

the inlet and the outlet must be at

normal atmospheric pressure.

Ensure the pump outlet is not clo-

sed or restricted.

½ Diaphragm and valve plates are the

only parts subject to wear. Wear is

usually indicated by a drastic

reduction in the pneumatic perfor-

mance. When replacing parts pro-

ceed as described in section 5.

½ Ambient conditions: see chapter

1.3.

4.2 Operation

Taking the pump into operation

ᕡ Plug the mains plug of the pump

into a properly installed safety

socket.

ᕢ Switch the pump on at the pump

mains switch (see fig. 1).

ᕣ If cyclic drying of the pump heads

is required in the current evacu-

ation process, switch the drying

system on at the mains switch of

the control system (not included in

scope of delivery).

Ī The drying system should only

be switched on if a container

has been attached to the pres-

sure line of the pump which will

catch the condensate; other-

wise the condensate will flow

out uncontrolled.

Check:

³ Tubing for correct tubing.

· Electrical connections for correct

connection.

After the evacuation/process has been

completed, take the pump out of ope-

ration:

ᕡ Purge the pump including the

connecting hoses with air at full

flow rate for about 5 minutes.

ᕢ If the drying system is switched

on:

Switch the drying system off at the

mains switch of control system

(not included in scope of delivery).

ᕣ Switch the pump off at the mains

switch of the pump.

ᕤ Pull the mains plug of the pump out

of the socket.

5. Servicing:

Changing Diaphragms and Valve

Plates/Sealings

The diaphragms in both pump heads

should be changed at the same time.

When diaphragms are changed, valve

plates/sealings should also be repla-

ced. If the diaphragms are not changed

in both heads at the same time or dia-

phragms and valve plates/sealings are

not changed at the same time the

nominal performance of the pump is

not guaranteed after the service.

If a pump has been used for

aggressive or toxic substances or

other types of substances which

are hazardous, hazardous to health,

or injurious, the following points

must be observed:

1.) Clean the pump and its compo-

nents before servicing.

2.) Ensure that the service personnel

is not subject to a health hazard.

Apply the safety and protection

measures that are necessary for

the medium that has been handled

by the pump (example: the use of

protective gloves).

3.) Ensure that discarded parts and

materials are safely and correctly

PM 16527-860.3-2.00 e 11/05

3

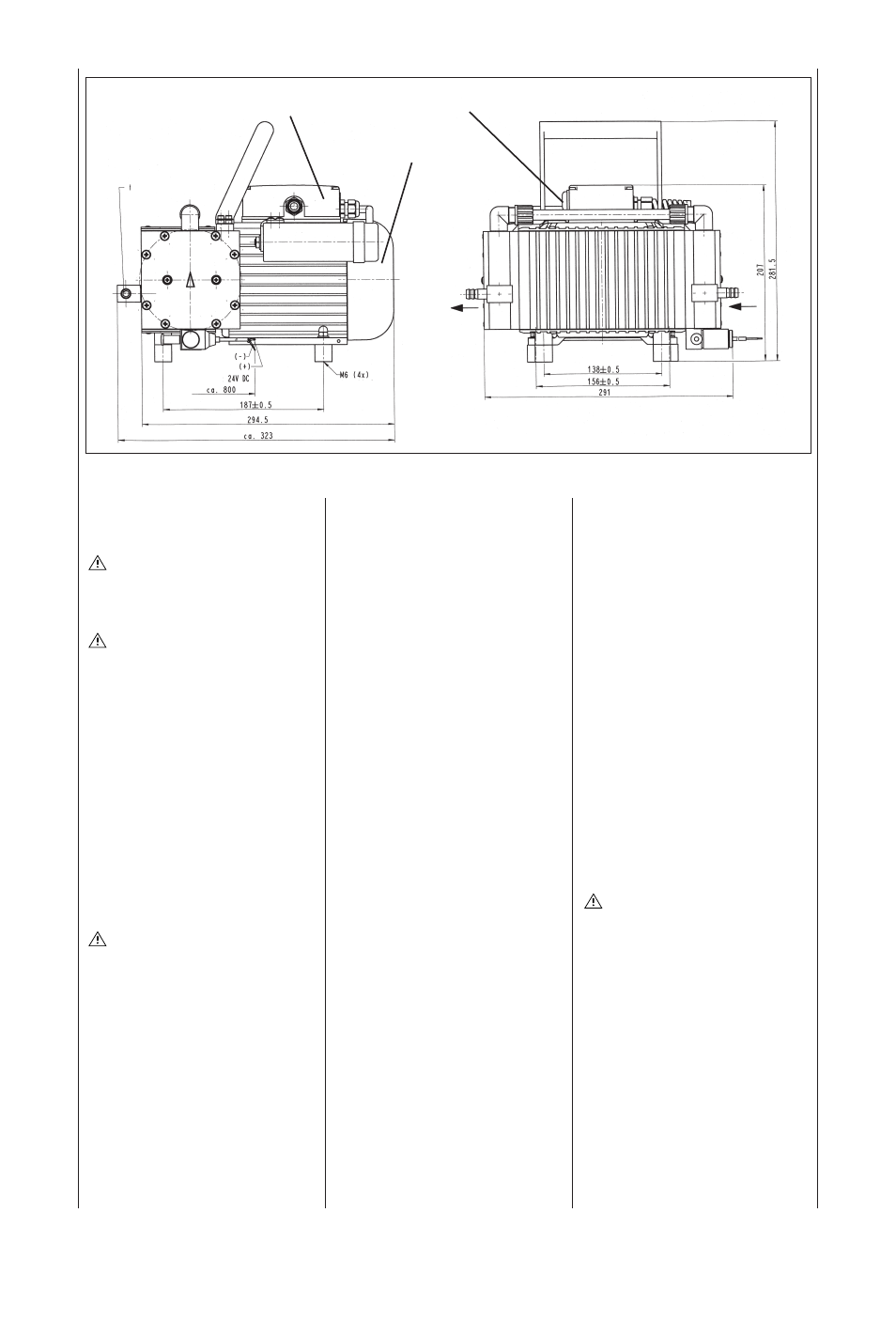

Fig. 1: Pump PM 16527-N 860.3-2.00

Fan cover

Connecting box of the pump

Mains switch

for tube ID 10

6 mm deep

blue

brown

voltage valve