Mayline Kwik-Track User Manual

Page 3

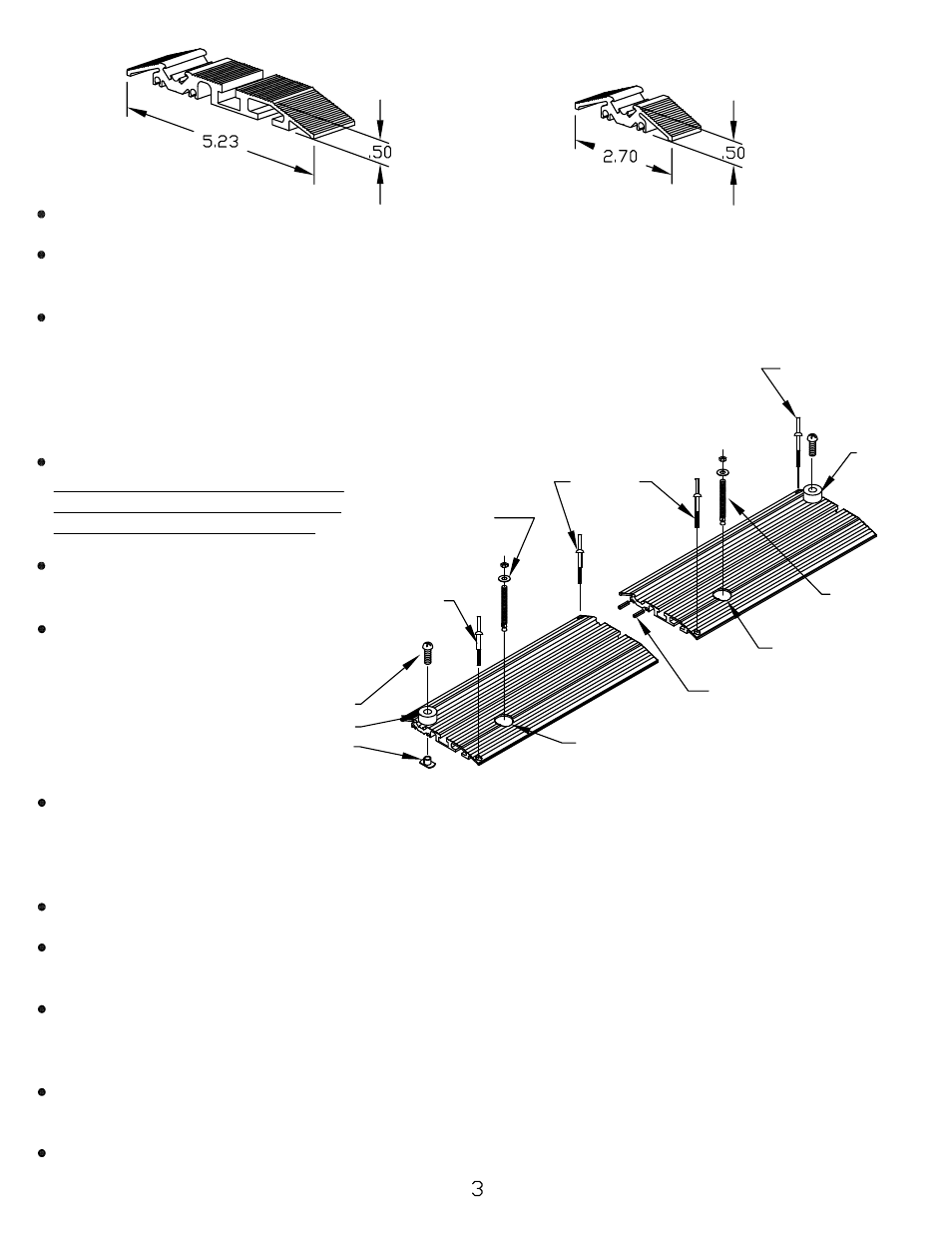

The In-track Anti-Tip track (MLTA) will be shipped with the Heavy-duty track (MLT).

Install Stationary Shelving per 'Typical Stationary Placement' drawing on Page 4.

Use stationary shelving to assist in aligning track and mobile carriages. The tracks

should extend beyond the stationary shelving at equal dimensions on either side.

Align assembled track parallel to stationary shelving or aisle with approximately

1 1/2" clearance from any obstacle. The MLTA track will be the rear track of the

two track lateral system. Using the holes in the track as a guide, drill 1/4" dia. holes

into the concrete floor deep enough for the track end fasteners. Clean concrete

dust from holes. Level track using shims provided.The track must

be supported along its entire length.

INSTALL END STOP ON ONE END OF MLTA TRACK.

BE SURE TEE NUT FOR OPPOSITE

BUMPER IS UNDER TRACK PRIOR

TO FINAL TRACK ANCHORING.

Hammer the fastener(s) into the floor

through holes in both ends of track.

Confirm joints are still properly

seated, track is straight and level.

MLTA Track

MLT Track

Maintaining careful alignment of the MLTA, drill a 3/8" hole into the floor and install the mid-track

3/8" x 3" HILTI KBTZ Concrete bolts at every available anchor point in the track. The strength of the

anti-tip is in the anchors. Make sure they are tightened properly.

CAUTION: Hole depth for 3/8" HILTI bolt must be a consistent depth as to prevent tripping hazard.

Once the anti-tip track is secured, the remaining tracks can be set in the approximate location.

Place one carriage on the track to determine spacing. Verify carriage wheels are centered in the

channels and in the track.

The tracks must be square, parallel, and level to each other to insure proper operation. Measure each

set of tracks and the entire system, corner to corner, to verify that each distance is the same. Once each

cross measurement is the same, the system is square and parallel.

When the tracks are square, parallel, level and shimmed as required drill the end holes. Install remaining

anchors. It is the installer's responsibility to verify smooth operation of the system.

Place the remaining carriages on the track, verify smooth operation and install the remaining end stops on

MLT and MLTA tracks.

End Stop

Anchor

Pin Hole

Anchor

Pin Hole

2" Nail-in

Fastener

Screw

End Stop

Tee Nut

Hilti KBTZ

Bolt 3/8" x 3"

Hilti KBTZ

Bolt 3/8" x 3"

Roll Pins

2" Nail-in

Fastener

2" Nail-in

Fastener

Tee Nut

Screw