Cutting methods – Longevity FORCECUT 50i User Manual

Page 25

Plasma Cutters www.LWELD.com

www.longevity-inc.com

21

LP-40D

Cutting Guideline Table

Cutting Methods

Different material thicknesses require different cutting techniques.

Thin material: Start perpendicular to the work piece. It is unnecessary to

angle or start on the edge, as the arc will pass through quickly.

Medium material: Angle the torch tip to avoid damaging the tip. Once the

arc passes through the material, you may begin cutting normally.

Thick material: Drill a pilot hole through which to start your arc, or start on

the edge of the work piece.

Never cut material on a flat surface. Raise the work piece above the surface to avoid

blow back which may burn you or cause fires

.

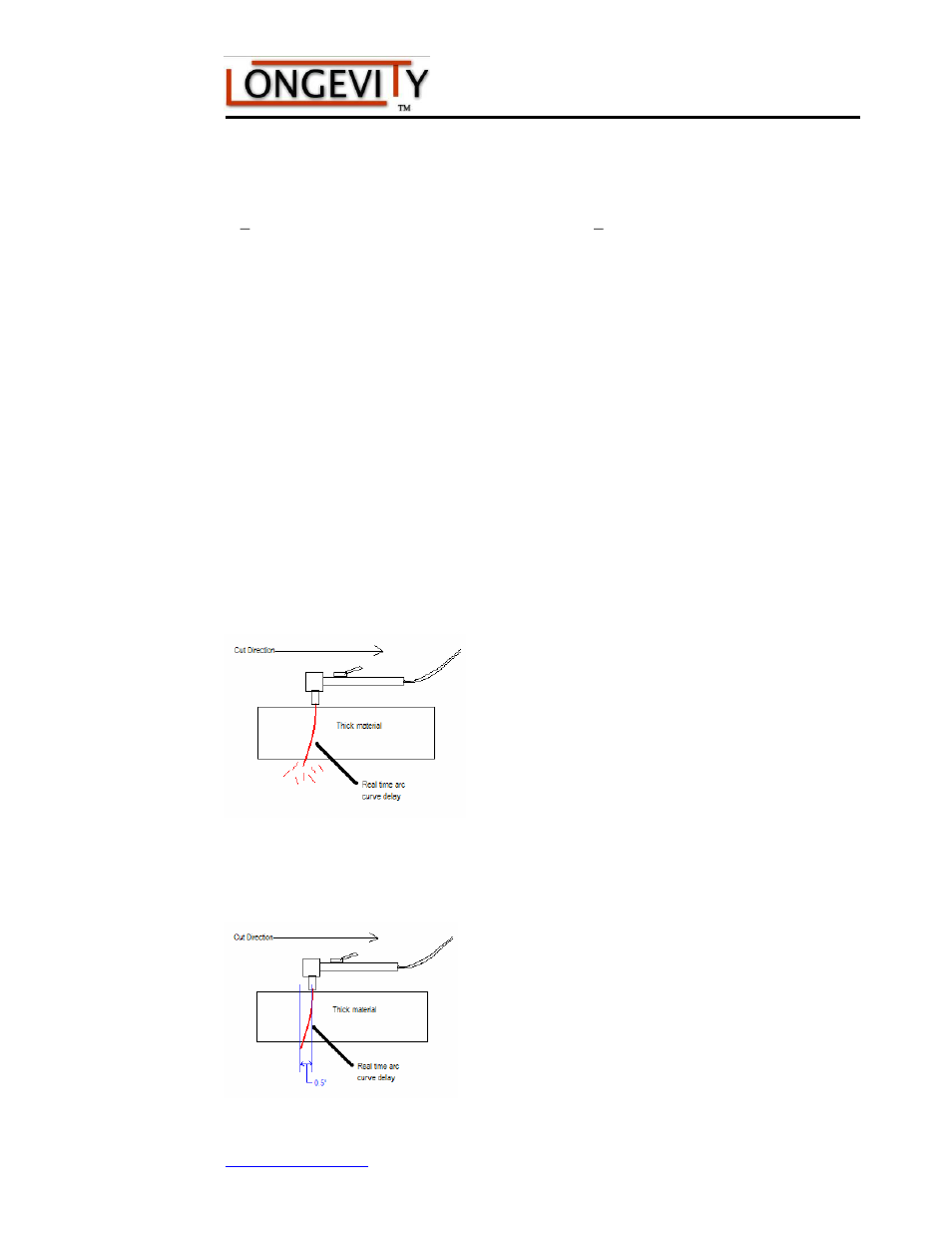

Real Time Arc-Curve Delay

When cutting thick materials you must maintain a steady even motion in the

direction of the cut. Moving the torch too quickly causes an arc-curve delay. An

arc-curve delay can leave the work piece with uncut sections, requiring you to re-cut

those sections, which could distort or damage the work piece.

To avoid arc-curve delay, allow the arc to pass completely through the work piece

before moving too far ahead. The arc-curve should lag not more than the thickness of

the material being cut. In other words, if the work piece is one-half inch thick, the arc

curve should lag not more than one-half inch behind the torch, as shown below.