Prepare the burner, Warning – Beckett AFG User Manual

Page 6

Page 6

RWB 6104 BAFG R02

Table 4. AFG Reduced Firing Rates

(with

LFRB)

Burner head type

Low Firing Rate Baffl e installed

F0

up to 0.65 gph

F3 or L1

up to 0.85 gph

F4 or F6

up to 0.90 gph

V1

up to 1.00 gph

Prepare the Burner

Low Firing Rate Baffl e

The AFG Low Firing Rate Baffl e (LFRB) reduces

the air fl ow and pressure. The LFRB is sometimes

used for fi ring rates under 1.00 gph as listed in

Table 4. Refer to the appliance manufacturer’s in-

structions. Do not omit the LFRB when specifi ed.

Omitting the baffl e when specifi ed or installing the

baffl e when not specifi ed could result in impaired

burner performance.

Burner fuel unit

Verify that the burner fuel unit is compatible with

the oil supply system. For more details, refer to

“Connect fuel lines” later in this manual.

y

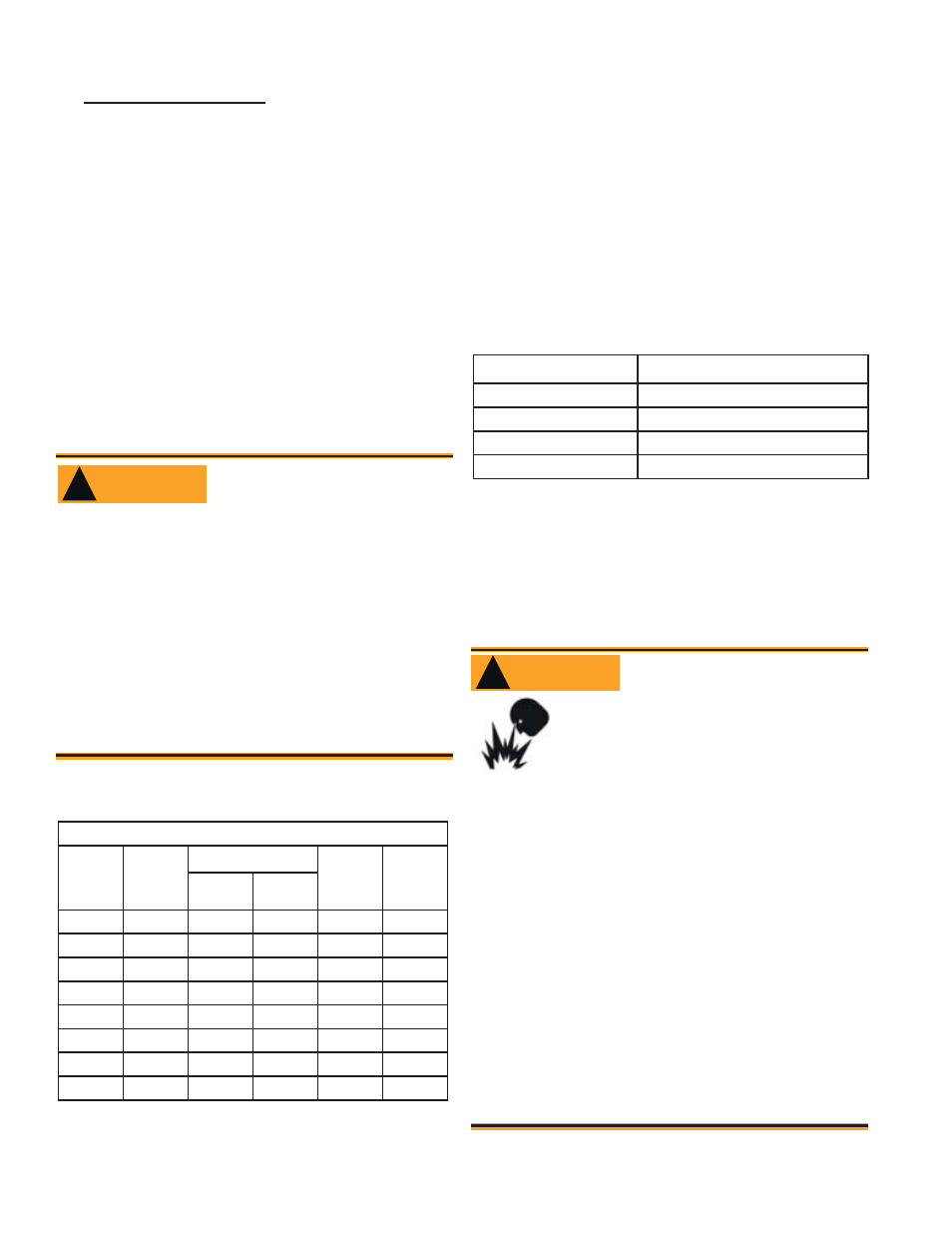

Chamber Dimensions (inches)

Firing

Rate

(GPH)

Round

I.D.

Rectangular

Height

Floor to

nozzle

Width

Length

0.50

8

7

8

12

5-6

0.75

9

8

9

12

5-6

1.00

10

9

10

12.5

5-6

1.25

11

10

11

12.5

5-6

1.50

12

11

12

13

6-7

2.00

14

12

15

13.5

6-7

2.50

16

13

17

14

7-8

3.00

18

14

18

15

7-8

Table 3. Chamber Dimensions

Outside air kit applications

Refer to separate instruction sheet supplied with

AF/AFG outside air kit for installation. This optional

kit allows combustion air to be piped directly to the

burner (Beckett part number 51747).

Clearances to burner and appliance

Provide space around burner and appliance for

easy service and maintenance.

Check minimum clearances against those shown

by the appliance manufacturer and by applicable

building codes.

Combustion chamber — Burner retrofi t-

ting

Verify that the appliance combustion chamber pro-

vides at least the minimum dimensions given in

Table 3.

y

y

When retrofi tting appliances that have unlined

stainless steel combustion chambers, protect the

chamber by lining the inside surfaces with a ce-

ramic fi ber blanket, such as a wet-pac or other

suitable refractory material.

Some steel chambers may not require liners be-

cause the appliance was designed and tested

for use with fl ame retention burners. Refer to the

manufacturer’s instructions.

y

y

Failure to comply could result in damage to the

heating equipment and result in fi re or asphyxi-

ation hazards.

WARNING

!

Protect Steel Combustion

Chamber From Burnout

Use only nozzles having the brand, fl ow rate (gph), spray

angle and pattern specifi ed by the appliance manufac-

turer.

Follow the appliance manufacturer’s specifi cations for the

required pump outlet pressure for the nozzle, since this

affects the fl ow rate.

Nozzle manufacturers calibrate nozzle fl ow rates

at 100 psig.

When pump pressures are higher than 100 psig,

the actual nozzle fl ow rate will be greater than the

gph stamped on the nozzle body. (Example: A

1.00 gph nozzle at 140 psig = 1.18 gph)

Securely tighten the nozzle (90 torque inch pounds). For

typical nozzle fl ow rates at various pressures refer to Ta-

ble 5.

y

y

Incorrect nozzles and fl ow rates

could result in impaired combus-

tion, under-fi ring, over-fi ring, soot-

ing, puff-back of hot gases, smoke

WARNING

!

Correct Nozzle and Flow

Rate Required

and potential fi re or asphyxiation hazards.

Nozzle and Pump Pressure