Ergo iii adjustable cruise mount & clevis, Rotating arm assembly installation, Footpeg and clevis installation and adjustment – Kuryakyn 4080 ERGO III ADJUSTABLE CRUISE MOUNT & CLEVIS User Manual

Page 4: Installation

PAGE

4

ROTATING ARM ASSEMBLY INSTALLATION:

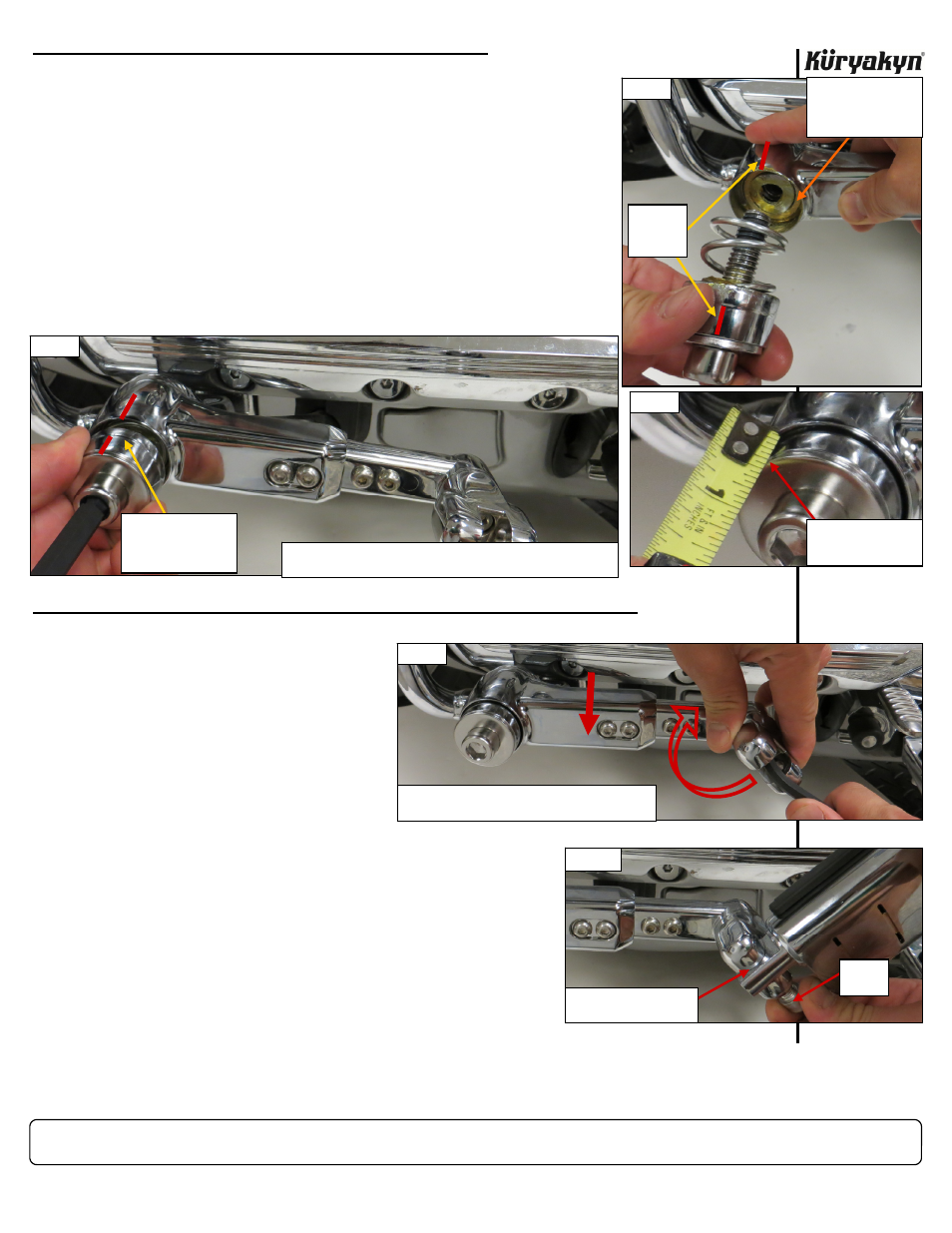

STEP 12

Position the Rotating Arm assembly (PIC 6 and 7) on the Ergo II mount

EXACTLY AS BEFORE in STEP 7. Ensure that the Arm is parallel to the

engine guard and valve cover.

STEP 13

Insert 1/2” Screw with the hardware (from STEP 11) through the Arm and

Helix. PIC 6 and 7 Torque the 1/2” Screw to 30 FT/LBS. Ensure the

marks (from STEP 6) stay aligned as you tighten the screw.

Step 14

Using a measuring tape or ruler, ensure that exactly 3/8” of the End Cap

protrudes from the assembly. PIC 8 Do not include the thickness of the

washer. If necessary, loosen the 1/2” Screw and “re-seat” the End Cap as

you re-tighten the screw. This will ensure that the End Cap is properly

aligned with the nose of the Helix.

FOOTPEG AND CLEVIS INSTALLATION AND ADJUSTMENT:

STEP 15

Refer to PIC 9. Remove the clevis-

mounting screw and apply some Blue

Loctite (248) to the threads. Reinstall

the screw. Push down on the Rotating

Arm until it reaches its stop; adjust the angle of the clevis so the

footpeg will fold up and back at an angle. Ensure the splines on

the clevis and arm engage and tighten the clevis-mounting screw.

Torque the screw to 20 FT/LBS.

Step 16

Apply some Blue Loctite (248) to the clevis screw threads. Install

the clutch-side footpeg in the clevis and secure it with the clevis

screw. PIC 10 If necessary, use the included Wave Washers to

take up any excess space between the footpeg adapter and the

clevis. Torque the screw to 25 FT/LBS.

STEP 17

Loosen the footpeg screw to adjust the footpeg angle. Tighten the

footpeg screw.

STEP 18

Repeat

STEPS 3 through 17 for the right side.

ERGO III ADJUSTABLE CRUISE MOUNT & CLEVIS

INSTALLATION

NOTE:

Place a drop of Loctite Thread-

locker Blue 248 on the threads of

the clevis and footpeg screws

before installing. Follow the

manufacturer’s recommendations

for proper application.

PIC 7

ENSURE THE ROTATING ARM IS AT LEAST PARALLEL WITH THE

ENGINE GUARD AND VALVE COVER

ENSURE MARKS STAY

ALIGNED AS YOU

TIGHTEN THE 1/2”

SCREW

PIC 6

ADD A DAB OF

GREASE TO KEEP THE

BUSHINGS IN THE

ARM

MARKS

FROM

STEP 6

ENSURE 3/8” OF END

CAP PROTRUDES

FROM ARM ASSEMBLY

PIC 8

-cont.-

PIC 9

PUSH DOWN ON THE ARM AND ADJUST THE CLEVIS

SO THE FOOTPEG WILL FOLD UP AND BACK.

PIC 10

USE A WAVE WASHER TO

TAKE UP EXCESS SPACE

CLEVIS

SCREW