Gast NL52 User Manual

Page 4

4

It is your responsibility to regularly inspect and make

necessary repairs to this product in order to maintain

proper operation.

Check intake and exhaust filters after first 500 hours of

operation. Clean filters and determine how frequently

filters should be checked during future operation. This

one procedure will help assure the motor’s performance

and service life.

Flushing

Flushing this product to remove excessive dirt, foreign

particles, moisture or oil that occurs in the operating

environment will help to maintain proper vane

performance. Flush the motor if it is operating slowly

or inefficiently.

Use only Gast recommended Flushing Solvent.

DO NOT use kerosene or ANY other combustible

solvents to flush this product.

1.

Disconnect air line and muffler.

2.

Add flushing solvent directly into motor. If using

liquid solvent, pour several tablespoons directly

into the intake port. If using spray solvent,

spray for 5-10 seconds into intake port.

3.

Rotate the shaft by hand in both directions for a

few minutes.

4.

You must wear eye protection for this step.

Cover exhaust with a cloth and reconnect the air

line.

5.

Restart the motor at a low pressure of

approximately 10 PSI / 0.7 bar until there is no

trace of solvent in the exhaust air.

6.

Listen for changes in the sound of the motor.

If motor sounds smooth, you are finished.

If motor does not sound like it is running smoothly,

installing a service kit will be required

(See “Service Kit Installation”).

Check that all external accessories such as relief valves

or gauges are attached and are not damaged before

operating product.

4.

Check the air compressor.

5.

Listen for changes in the sound of the motor.

If motor sounds smooth, you are finished.

If motor does not sound like it running smoothly,

installing a service kit will be required

(See “Service Kit Installation”).

MAINTENANCE

Shutdown

It is your responsibility to follow proper shutdown

procedures to prevent product damage.

1.

Turn off air intake supply.

2.

Disconnect air supply and vent all air lines.

3.

Disconnect air lines.

4.

Remove air motor from connecting machinery.

5.

Remove the muffler.

6.

Wear eye protection. Keep away

from air stream. Use clean, dry air

to remove condensation from the inlet port of

the motor.

7.

Plug or cap each port.

8.

Coat output shaft with oil or grease.

9.

Store motor in a dry environment.

Cleaning sound absorber

1.

Remove the sound absorber.

2.

Clean the felt filter.

3.

You must wear eye protection for this step.

Gast will NOT guarantee field-rebuilt product

performance. For performance guarantee, the product

must be returned to a Gast Authorized Service Facility.

SERVICE KIT INSTALLATION

Service Kit contents vary. Most contain vanes, end cap

gasket, body gasket, bearings and a muffler element or

felt.

Major and Minor Rebuilds Tool kits which include a

more in-depth rebuild manual are available through your

Gast Distributor/Representative. These kits include the

tools required to remove and reassemble end plates,

bearings and shaft seals, and to set the proper end

clearance. The rebuild manual also includes step by

step instructions, including illustrations, to help achieve

a successful rebuild. Gast Manufacturing, Inc. highly

recommends using the air motor rebuild manual and

tool kit when attempting a minor or major rebuild to

your Gast air motor.

Minor Rebuild:

1.

Remove the end cap.

2.

Remove dead end plate bolts.

3.

Remove dead end plate. (Use factory issued tool,

do not use screwdriver to remove the end plate.)

4.

Remove the dowel pins from the body and push

back into end plate until flush or just below the

machined surface of the end plate.

5.

Remove vanes.

6.

Clean parts. Check for scoring on the end plate

and rotor assembly. If scoring exists, send unit to

a Gast authorized service facility.

7.

Install vanes. Angle cuts on vanes face to

center of rotor.

8.

Place the proper end plate gasket on the end

plate. If the original is damaged, replace with a

new one supplied in the Service Kit.

9.

Place the dead end plate on the body.

10.

Press the bearing onto the shaft using a factory

supplied bearing pusher.

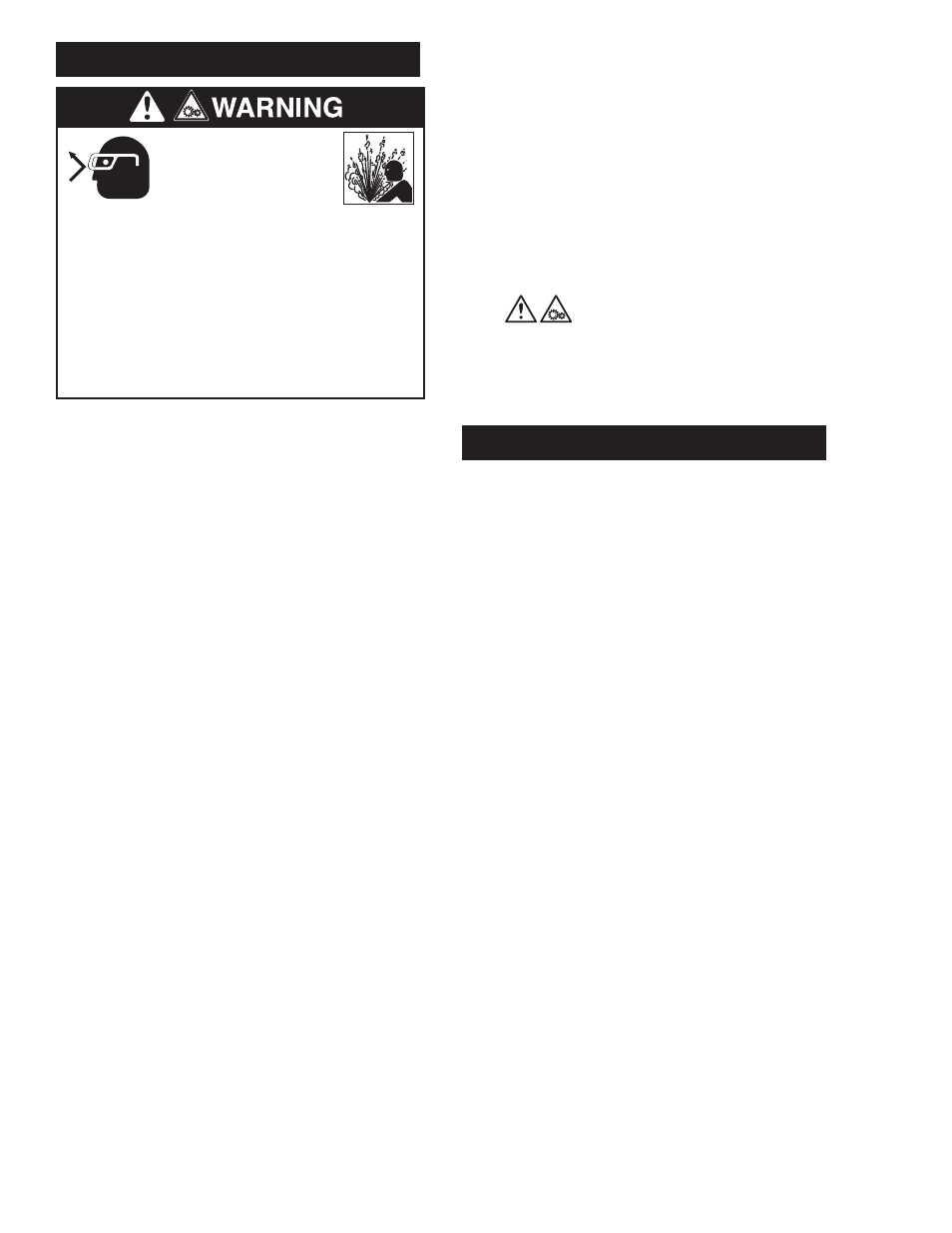

Injury Hazard

Disconnect air supply and vent all air lines.

Wear eye protection when flushing this product.

Air stream from product may contain solid or liquid

material that can result in eye or skin damage.

Flush this product in a well ventilated area.

DO NOT use kerosene or other combustible solvents

to flush this product.

Failure to follow these instructions can result in

burns, eye injury or other serious injury.