Gast NL52 User Manual

Page 3

Check the direction of the motor airflow. A single

rotation motor will operate properly only in one

direction.

Single rotation motors require a sound absorber to be

connected to the exhaust air port. Remove the plastic

shipping plugs from the ports. Save plugs for future

use during shutdown.

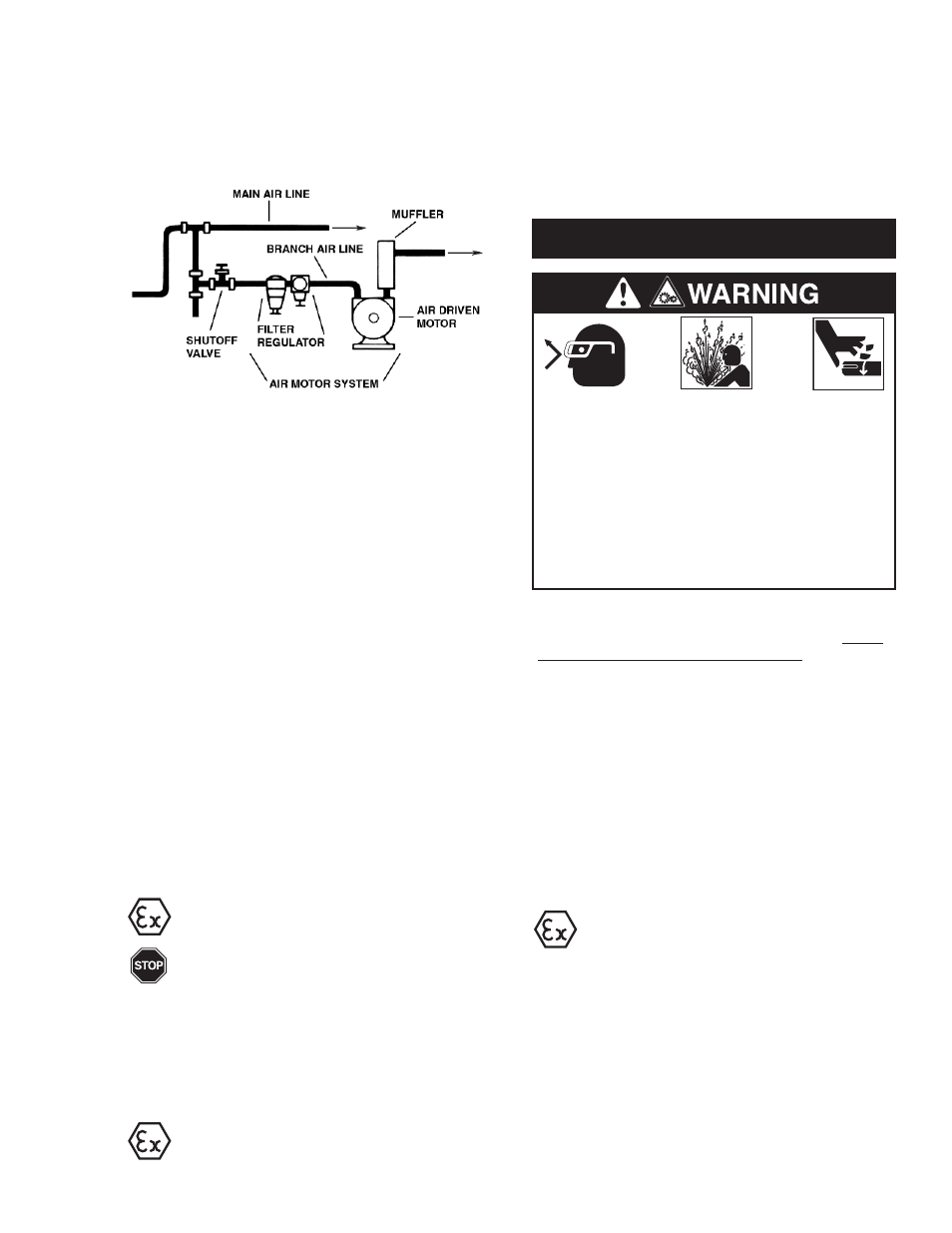

Install a 5-micron filter in the air line before the

connection to the motor. Next install an air pressure

regulator to control motor speed and torque.

Clean the compressed air connection with low pressure

air to remove any dirt from the line before connecting to

the ports.

Use the proper sized fasteners. For the most efficient

output and control of speed, use air lines that are the

same size as the motor inlet port if the connection is

less than 7 feet (2 meters). For longer connections, use

the next pipe size larger than the motor intake port.

Connect lines to motor in the proper direction.

Connect the sound absorber on the exhaust air port or

valve connection.

3

Do not add any thrust to the end or side of the shaft

when making connections.

Lubricating the drive shaft will make assembly

easier. Use a puller for removal of pulleys,

couplings and pinions on the motor shaft.

Check that the tension on the belt pulley

matches the manufacturer’s specifications. Do not

exceed the maximum radial and axial forces on the

shaft. If the motor shaft is connected to the part to be

driven without a coupling, check that the radial offset

and axial force effect will not cause problems.

Do not use a hammer on the shaft or

connections.

Use only belts with < 10

9

electrical leakage

resistance to prevent static electrical problems.

Ground the motor.

Accessories

A muffler is shipped with the air motor (except 16AM)

but is not installed. Consult your Gast

Distributor/Representative for additional filter

recommendations. Install a moisture trap and 5 micron

filter in the air line ahead of motor.

Air consumption data at various speeds and pressures

are available from your Gast Distributor/Representative

or the factory.

Check all connections before starting motor. It is your

responsibility to operate this product at recommended

speeds, loads and room ambient temperatures. Do not

run the motor at high speeds with no load. This will

result in excessive internal heat that may cause motor

damage.

OPERATION

The starting torque is less than the running torque. The

starting torque will vary depending upon the position of

the vanes when stopped in relation to the air intake

port.

Use a pressure regulator and/or simple shut-off valve to

regulate the motor’s speed and torque. This will

provide the required power and will conserve air. Open

the air supply valve to the motor. Set the pressure or

flow rate to the required speed or torque.

Mounting

This product can be installed in any orientation. Mount

the motor to a solid metal base plate that is mounted to

a stable, rigid operating surface. Use shock mounts to

reduce noise and vibration. Install a pressure regulator

or simple shut-off valve to control motor.

Connection

Operate the motor for approximately 2 hours at

the maximum desired load. Measure the

surface temperature of the motor on the casting

opposite the pipe ports. The maximum surface

temperature listed on the motor is for normal

environmental and installation conditions. For most air

motors, the maximum surface temperature should not

exceed 266ºF/130ºC. Do not continue to operate the

motor if the measured surface temperature exceeds

temperature listed on the motor. If your measured

temperature does exceed listed value, consult with your

Gast Distributor/Representative for a recommendation.

Injury Hazard

Air stream from product may contain solid or liquid

material that can result in eye or skin damage.

DO NOT use combustible gases to drive this motor.

Wear hearing protection. Sound level from motor

may exceed 85 db(A).

Failure to follow these instructions can result in

burns, eye injury or other serious injury.