Fuelab 51502 Fuel Pressure Regulator User Manual

Page 2

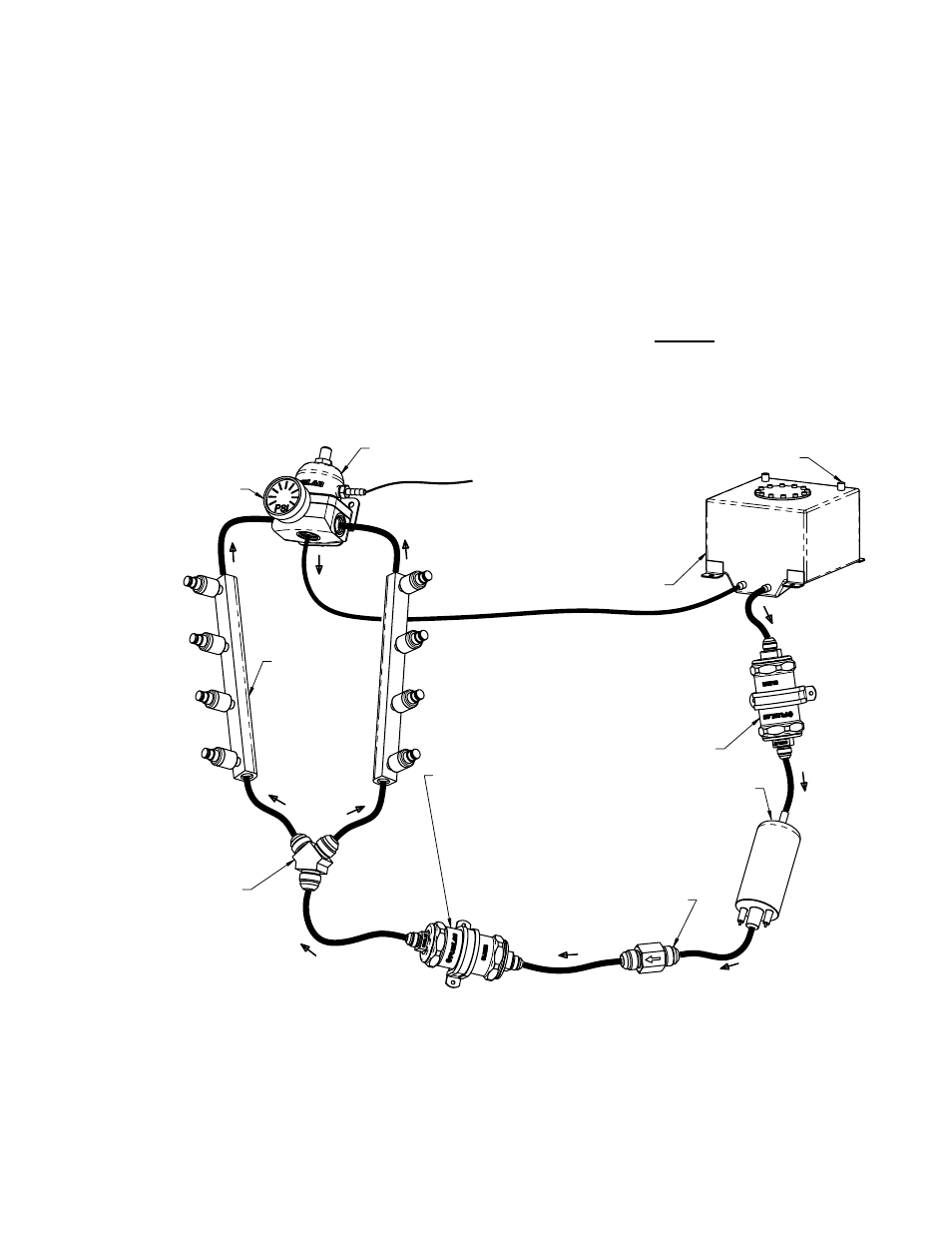

To Engine Intake Manifold

51502 Regulator

Fuel Gauge Shown in

Gauge Port, Liquid Filled

Gauge may have Error Due

to Temperature Variations.

Fuel Straining Filter Required, Typical

Micron Rating: 75-150, Fuelab

75 Micron Filter Recommended. Straining

Filter may be Installed in Fuel Pump,

Consult Pump Manufacturer's Specifications.

Y-Block or "T" Fitting,

to Split Flow into Two

Fuel Rail System

Vented Fuel Cell or Fuel Tank.

Tank must be Plumbed According

to Maximum Pump Flow Rate.

Consult Pump Manufacturer's

Specifications and Recommendations.

Follow Fuel Cell Manufacturer's

Recommendations for Proper

Cell Vent Plumbing

Fuel Filter with 60 Micron or

Lower Particle Rating is Required.

Fuelab Filter with 6, 10 or 40

Micron Rating is Recommended.

(2X) Fuel Rails

with Injectors

High Pressure

Electric Fuel Pump

Check Valve Required for Reduced

Vehicle Emissions and Improved

Engine Starting. Valve may be Installed

in Fuel Pump,Typical OEM Pumps

do have this Valve Installed. Consult

Pump Manufacturer's Specifications

105020121-1, Rev A Sheet 2 of 4

Plumbing Planning Notes:

Minimize plumbing restrictions between fuel rail(s) and regulator for peak performance, use –6AN (3/8”) to –10AN

(5/8”) line as required per flow rate requirements of the vehicle’s engine and fuel pump. Typical performance EFI

applications use a “Y” block or “T” fitting to split the output of the fuel pump into one end of each fuel rail (for dual

fuel rail application). The opposite end of each fuel rail is plumbed to the Inlet Ports of the regulator. Plumb the

return line back to the fuel tank. Use of a –6AN (3/8”) return line is typically recommended for this model of

regulator. See diagram on next page as well as diagram below, to identify the ports used on the regulator. If only

one fuel rail is used for the application, use a –6AN plug (not supplied) and supplied –906 O-ring to plug the unused

Inlet Port (“Y” block or “T” fitting not required in this case). The fuel line used must handle high pressure. The use

of fuel line such as stainless steel braided line and “AN” style fitting connections is recommended. The fuel ports

(two –6AN Inlet Ports and one –6AN Return Port) use “AN” or “military” style fittings. This plumbing standard is

commonly used with racing and high performance applications. See step 6 on next page for additional information

on this port standard. A fuel filter with a 60 micron or lower particle rating is required to be used upstream of

regulator and downstream from fuel pump to protect it and the fuel injectors from foreign object damage. Reference

the Schematic Diagram below for filter locations. Use of a liquid filled gauge exposed to engine compartment heat

is not recommended as the liquid inside the gauge may exert measurement errors. DO NOT plumb gauge port to

any gauge mounted inside the vehicle or in passenger compartment. A line burst can spill fuel inside passenger

compartment and on occupants, possibly causing serious injury or death. An electric gauge or pressure transducer

system is recommended for readings in a passenger compartment.

Typical EFI V-8 Fuel System Schematic Diagram:

Installation Steps:

1. Disconnect the ground terminal from battery and allow the vehicle’s engine and exhaust system to cool.

Relieve fuel system per applicable service manual. Follow all Warnings and Cautions written on previous page

of these instructions.

2. Modify, remove or replace other fuel system components as required per established build plan (reference

notes on previous page and above).

3. Use the supplied bracket as a drilling template to mark holes for mounting bracket. Choose a location that

minimizes exposure to excessive heat, near fuel rails. Mounting bracket can be modified as required. Use

clear or colored enamel paint to protect bracket surface after any modification.

Plumbing Planning Notes:

Minimize plumbing restrictions between fuel rail(s) and regulator for peak performance, use –6AN (3/8”) to –10AN

(5/8”) line as required per flow rate requirements of the vehicle’s engine and fuel pump. Typical performance EFI

applications use a “Y” block or “T” fitting to split the output of the fuel pump into one end of each fuel rail (for dual

fuel rail application). The opposite end of each fuel rail is plumbed to the Inlet Ports of the regulator. Plumb the

return line back to the fuel tank. Use of a –6AN (3/8”) return line is typically recommended for this model of

regulator. See diagram on next page as well as diagram below, to identify the ports used on the regulator. If only

one fuel rail is used for the application, use a –6AN plug (not supplied) and supplied –906 O-ring to plug the unused

Inlet Port (“Y” block or “T” fitting not required in this case). The fuel line used must handle high pressure. The use

of fuel line such as stainless steel braided line and “AN” style fitting connections is recommended. The fuel ports

(two –6AN Inlet Ports and one –6AN Return Port) use “AN” or “military” style fittings. This plumbing standard is

commonly used with racing and high performance applications. See step 6 on next page for additional information

on this port standard. A fuel filter with a 60 micron or lower particle rating is required to be used upstream of

regulator and downstream from fuel pump to protect it and the fuel injectors from foreign object damage. Reference

the Schematic Diagram below for filter locations. Use of a liquid filled gauge exposed to engine compartment heat

is not recommended as the liquid inside the gauge may exert measurement errors. DO NOT plumb gauge port to

any gauge mounted inside the vehicle or in passenger compartment. A line burst can spill fuel inside passenger

compartment and on occupants, possibly causing serious injury or death. An electric gauge or pressure transducer

system is recommended for readings in a passenger compartment.

Typical EFI V-8 Fuel System Schematic Diagram:

Installation Steps:

1. Disconnect the ground terminal from battery and allow the vehicle’s engine and exhaust system to cool.

Relieve fuel system per applicable service manual. Follow all Warnings and Cautions written on previous page

of these instructions.

2. Modify, remove or replace other fuel system components as required per established build plan (reference

notes on previous page and above).

3. Use the supplied bracket as a drilling template to mark holes for mounting bracket. Choose a location that

minimizes exposure to excessive heat, near fuel rails. Mounting bracket can be modified as required. Use

clear or colored enamel paint to protect bracket surface after any modification.