Fuelab 40401 Reduced Size EFI In-Line Fuel Pump User Manual

Page 2

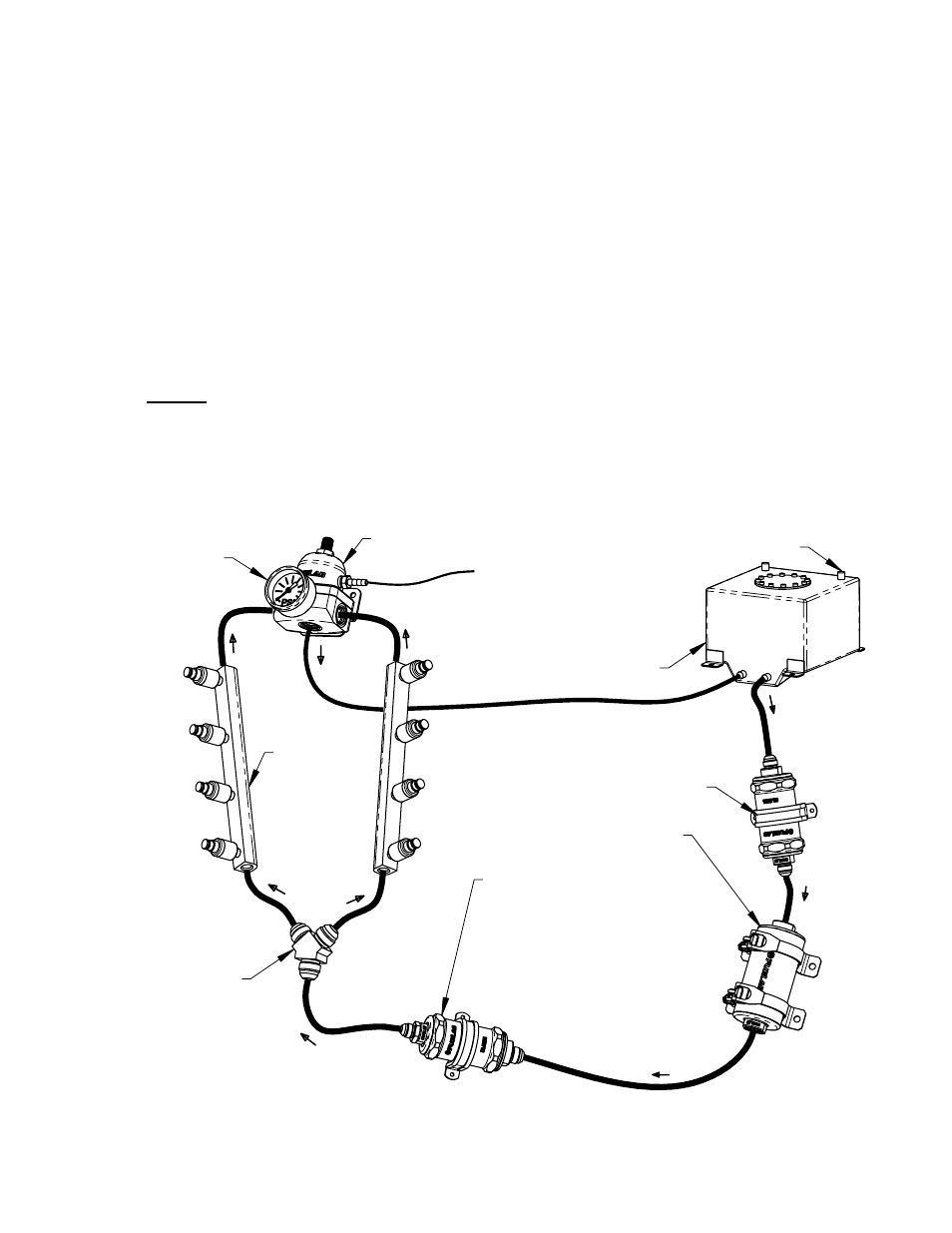

Typical EFI V-8 Fuel System Plumbing Schematic Diagram:

110020275-1, Rev A Page 2 of 6

An electronic gauge or pressure transducer system is recommended for readings in a passenger compartment.

Do not "Dead Head" Fuel Pump.

Special Note: Use in carbureted systems require a bypass return or relief valve.

Fuel Pump may be mounted inside a fuel tank or cell, inlet screen strainer is still required. Adequate structural

mounting and support is the responsibility of the fabricator and installer. Mount the fuel pump as low as possible

without it being vulnerable to road hazards or debris. Minimize the length of the fuel line feeding fuel pump. Do not

use “cross drilled” style 90° elbow fittings, check valves or other restrictions (other than high flow fuel filter strainer

or shut-off valve) before or upstream of fuel pump. Minimize plumbing restrictions between fuel tank and fuel pump

and regulator for peak performance, use -8AN (1/2”) to -10AN (5/8”) line as required per flow rate requirements of

the vehicle’s engine and fuel pump speed setting. Typically -6AN (3/8”) to -8AN (1/2”) line is required for the rest

of the fuel system, after or upstream of fuel pump. Use of a strainer filter upstream of fuel pump is required to

protect fuel pump from damage. All fuel line used must handle high pressure. The use of fuel line such as stainless

steel braided line and “AN” style fitting connections is recommended. The fuel ports (one -10AN Inlet Port and one

-10AN Outlet Port) use “AN” or “military” style fittings. This plumbing standard is commonly used with racing and

high performance applications. See step 4 on page 5 for additional information on this port standard. A fuel filter

with a 60 micron or lower particle rating is required to be used upstream of regulator and downstream from fuel

pump to protect it and the fuel injectors from foreign object damage. Reference the Schematic Diagram below for

filter locations. Fuel tank must have a modification of an additional sump, or use aftermarket fuel cell as indicated.

Use of a “pick-up” tube system is not recommended. Use of a liquid filled gauge exposed to engine compartment

heat is not recommended as the liquid inside the gauge may exert measurement errors, all mechanical gauges and

pressure transducers have amounts of error due to temperature fluctuation, be aware of inaccurate pressure

readings. DO NOT plumb gauge port to any gauge mounted inside the vehicle or in passenger compartment. A

line burst can spill fuel inside passenger compartment and on occupants, possibly causing serious injury or death.

Plumbing Planning Notes:

EFI Regulator

To Engine Intake Manifold (Air)

Fuel Gauge Shown in

Gauge Port, Liquid Filled

Gauge may have Error Due

to Temperature Variations.

Y-Block or "T" Fitting,

to Split Flow into Two

Fuel Rail System

Fuel Straining Filter Required, Typical

Micron Rating: 75-150, Fuelab 818xx

Series 75 Micron Filter Recommended.

-8AN or 1/2" Miniumum

Line Size Required to feed Straining

Fuel Filter and Fuel Pump.

Vented Fuel Cell or Fuel Tank.

Tank must be Plumbed According

to Maximum Pump Flow Rate.

Follow Fuel Cell Manufacturer's

Recommendations for Proper

Cell Vent Plumbing

Fuel Filter with 60 Micron or

Lower Particle Rating is Required.

Fuelab Filter with 6, 10 or 40

Micron Rating is Recommended.

Check Valve Required for Reduced

Vehicle Emissions and Improved

Engine Starting. Fuelab 848xx Series

Filter has Check Valve Assembly

Built in.

(2X) Fuel Rails

with Injectors

40401-c (-sp) Fuel Pump