Maintenance, Warning – Briggs & Stratton Proseries User Manual

Page 12

12

BRIGGSandSTRATTON.COM

General Recommendations

To ensure efficient operation and longer life of the air

compressor, prepare and follow a routine maintenance

schedule. The routine described in this section is intended for

an air compressor used under normal daily working conditions.

If necessary, modify the schedule to suit the conditions under

which you use your compressor. Modifications will depend

upon hours of operation and working environment. Operating

air compressors in extremely dirty or hostile environments will

require more frequent maintenance checks.

NOTE: See Features and Controls and Operation for control

locations.

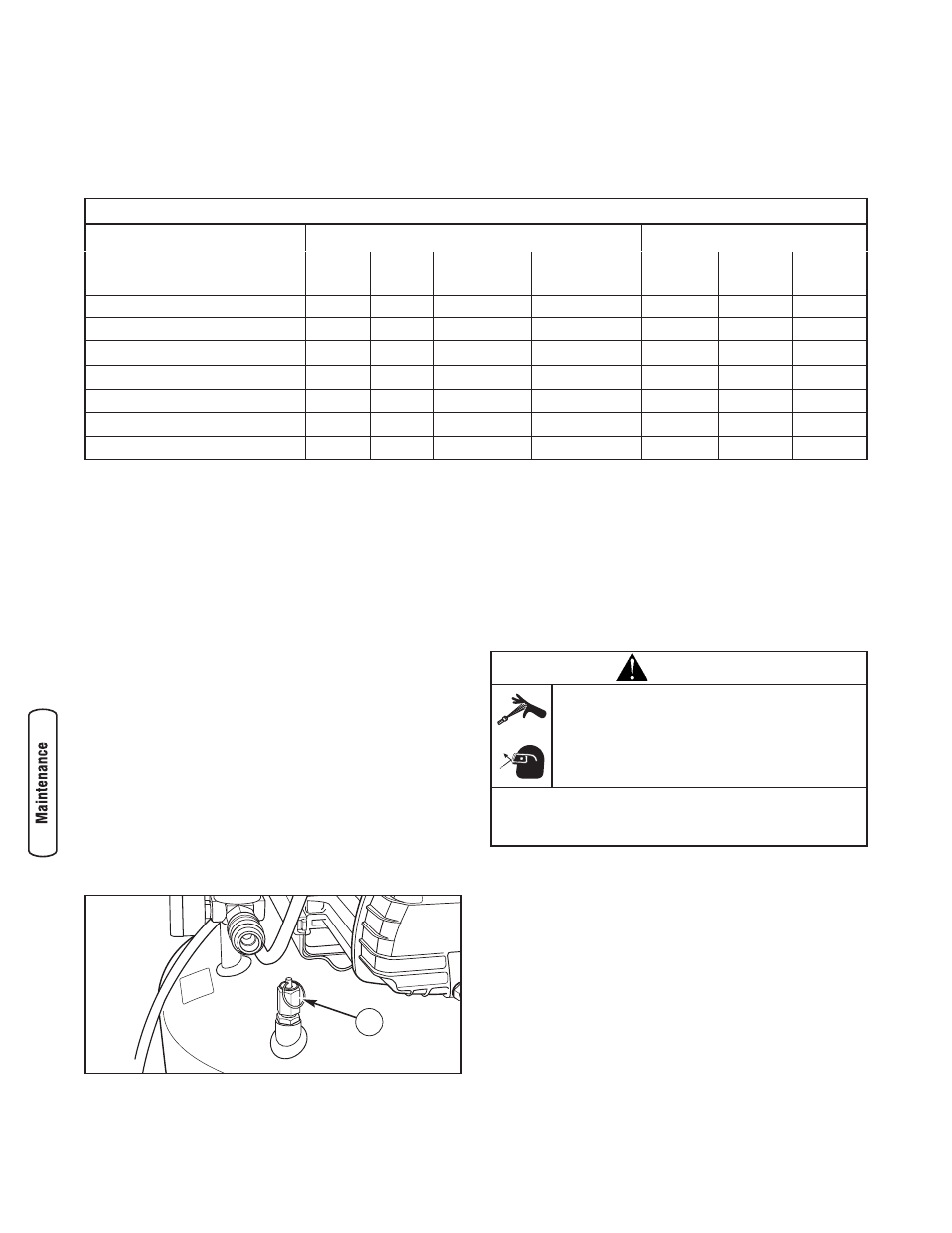

Inspect Safety Valve

1. Pull ring on safety valve (A) and observe that safety

valve operates freely.

2. If valve is stuck or does not operate smoothly, it must

be replaced with same type of valve. Take unit to

authorized service facility for repair.

Inspect Tank Drain Valve

1. Push ON - OFF switch to OFF and unplug unit.

2. Disconnect air tool or accessory from unit.

3. Pull ring on safety valve to reduce air pressure. Release

safety valve ring.

4. Open drain valve (turn fully counterclockwise) and

permit accumulated water to be discharged. Valves

should operate smoothly and have full range of

operation.

5. After water has drained, close drain valve fully

clockwise.

NOTE: If drain valve is plugged, pull safety valve ring to fully

drain air from tank. Remove, clean and reinstall drain valve

using pipe thread sealant.

Maintenance

Maintenance Schedule

Follow the hourly or calendar intervals, whichever occurs first. More frequent service is required when operating in adverse

conditions noted below.

* Change oil after first 100 hours of operation, then every 300 hours thereafter.

** Inspect anually, replace as necessary.

Maintenance Schedule - Fill in Dates as You Complete Regular Service

Maintenance Task

Service Intervals

Service Dates

Daily

Weekly

Every 50 Hours

or Yearly

Every 100 Hours

or Yearly

Inspect safety valve

X

Inspect fittings/valves

X

Inspect oil level

X

Clean unit

X

Inspect and clean air filter

X

Change pump oil

X*

Inspect safety labels

X**

A

WARNING

Compressed air stream from hose or tank drain

can cause soft tissue damage to exposed skin

and can propel objects leading to severe injury

and / or property damage.

• DO NOT direct air stream at self or others.

• Always wear ANSI Z87.1 approved safety glasses with side

shields.