Installation procedure, Product features – FastenMaster HeadLOK User Manual

Page 2

INSTALLATION PROCEDURE

Using a

1

⁄

2

" high torque drill (18V cordless or higher), drive the HeadLok head flush to the surface. No predrilling

required when proper end and edge distances are maintained.

* SCL=Structural Composite Lumber (LVL,PSL and LSL)

** Wood species identified typically have average specific gravity similar to the values shown on this table.

All design values based on 1

1

⁄

2

" side member thickness and penetration into main member as follows: HeadLok 2",

Nails 10x diameter, Lags 8x diameter. Design values may be subject to adjustment factors (section 10.3 in NDS)

based on conditions existing during installation as well as those expected during service life.

The lag screw and nail design values included in these tables are compiled directly from the 2005 National Design

Specification for Wood Construction (2005 NDS). HeadLok design value calculations are based on independent lab

testing as outlined in ICC Acceptance Criteria AC233. All values have been reviewed and certified by a professional

engineer.

The statement “Faster, Easier, Stronger than

3

⁄

8

" lag screws” refers to the comparison of design shear values of

HeadLoks and

3

⁄

8

" lag screws.

A design professional should be consulted when making critical connections to ensure the proper number and location

of all fasteners meet national and local code requirements.

For technical assistance or questions regarding proper use of this fastener, please contact FastenMaster Technical

Support at 800.518.3569 or visit www.FastenMaster.com.

FMHLGMSHEET (211)

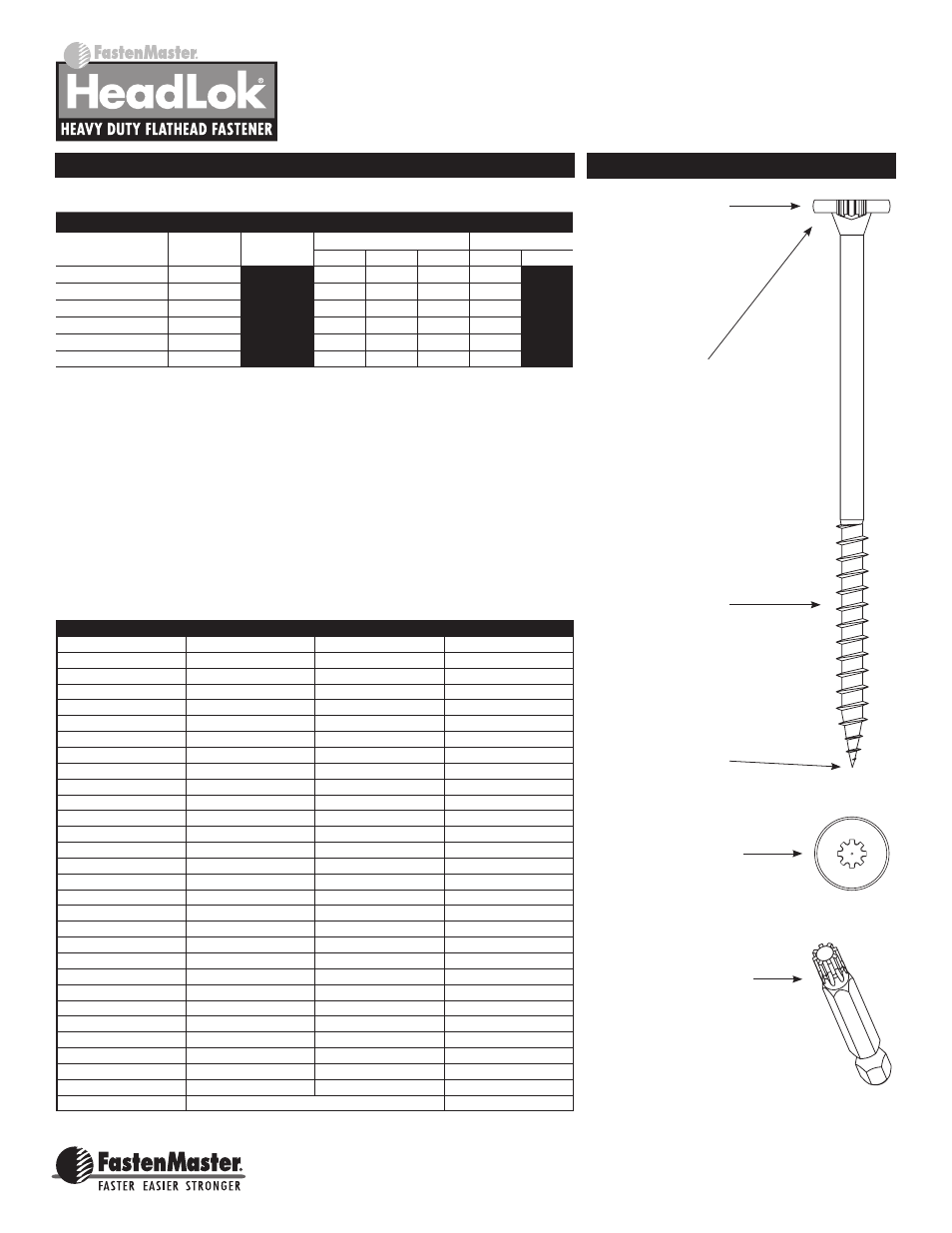

Spider drive

bit included

AggreSSive

threAd for

holding And

withdrAwAl

Strength

chAmfer under

heAd for

increASed

Strength

Spider drive

™

SyStem deSign

offerS high level

of bit engAgement

And drivAbility

ShArp gimlet

point for fASt

inStAllAtion

wAfer heAd

eliminAteS need

for wASher And

offerS increASed

pull through

Strength

item #

Screw length

Quantity per pack

driver bits included

FMHLGM278-12

2

7

⁄

8

"

12

1

FMHLGM412-12

4

1

⁄

2

"

12

1

FMHLGM006-12

6"

12

1

FMHLGM278-50

2

7

⁄

8

"

50

1

FMHLGM334-50

3

3

⁄

4

"

50

1

FMHLGM412-50

4

1

⁄

2

"

50

1

FMHLGM005-50

5"

50

1

FMHLGM006-50

6"

50

1

FMHLGM278-500

2

7

⁄

8

"

500

3

FMHLGM334-250

3

3

⁄

4

"

250

3

FMHLGM412-250

4

1

⁄

2

"

250

3

FMHLGM005-250

5"

250

3

FMHLGM512-250

5

1

⁄

2

"

250

3

FMHLGM006-250

6"

250

3

FMHLGM612-250

6

1

⁄

2

"

250

3

FMHLGM007-250

7"

250

3

FMHLGM712-250

7

1

⁄

2

"

250

3

FMHLGM008-250

8"

250

3

FMHLGM812-250

8

1

⁄

2

"

250

3

FMHLGM009-250

9"

250

3

FMHLGM912-250

9

1

⁄

2

"

250

3

FMHLGM010-250

10"

250

3

FMHLGM011-250

11"

250

3

FMHLGM012-250

12"

250

3

FMHLGM013-250

13"

250

3

FMHLGM014-250

14"

250

3

FMHLGM015-250

15"

250

3

FMHLGM016-250

16"

250

3

FMHLGM018-250

18"

250

3

FMSPIDER3-2PK

Driver Bit for HeadLok w/Spider Drive

2

PRODUCT FEATURES

lateral design values (in pounds per fastener) for single shear connections loaded perpendicular to grain

Wood

Specific

Gravity**

FastenMaster

HeadLok

Nails

Lags

10D

16D

20D

1

⁄

4

"

3

⁄

8

"

Red Oak

0.67

299

154

184

222

140

160

Southern Pine

0.55

257

128

154

185

120

140

Doug. Fir-L, SCL*

0.50

240

118

141

170

110

130

Doug. Fir-S

0.46

226

109

131

157

100

120

Hem. Fir

0.43

215

102

122

147

100

120

E. Spruce, W. Cedar

0.36

189

87

104

126

90

100

FASTENMASTER, INC., 153 BOWLES ROAD, AGAWAM, MA 01001

800.518.3569 WWW.FASTENMASTER.COM

FastenMaster

®

, Spider Drive

™

and HeadLok

®

are trademarks of OMG, Inc. Copyright ©2011 OMG, Inc. All rights reserved.