Installation procedure, Product features – FastenMaster LedgerLOK User Manual

Page 2

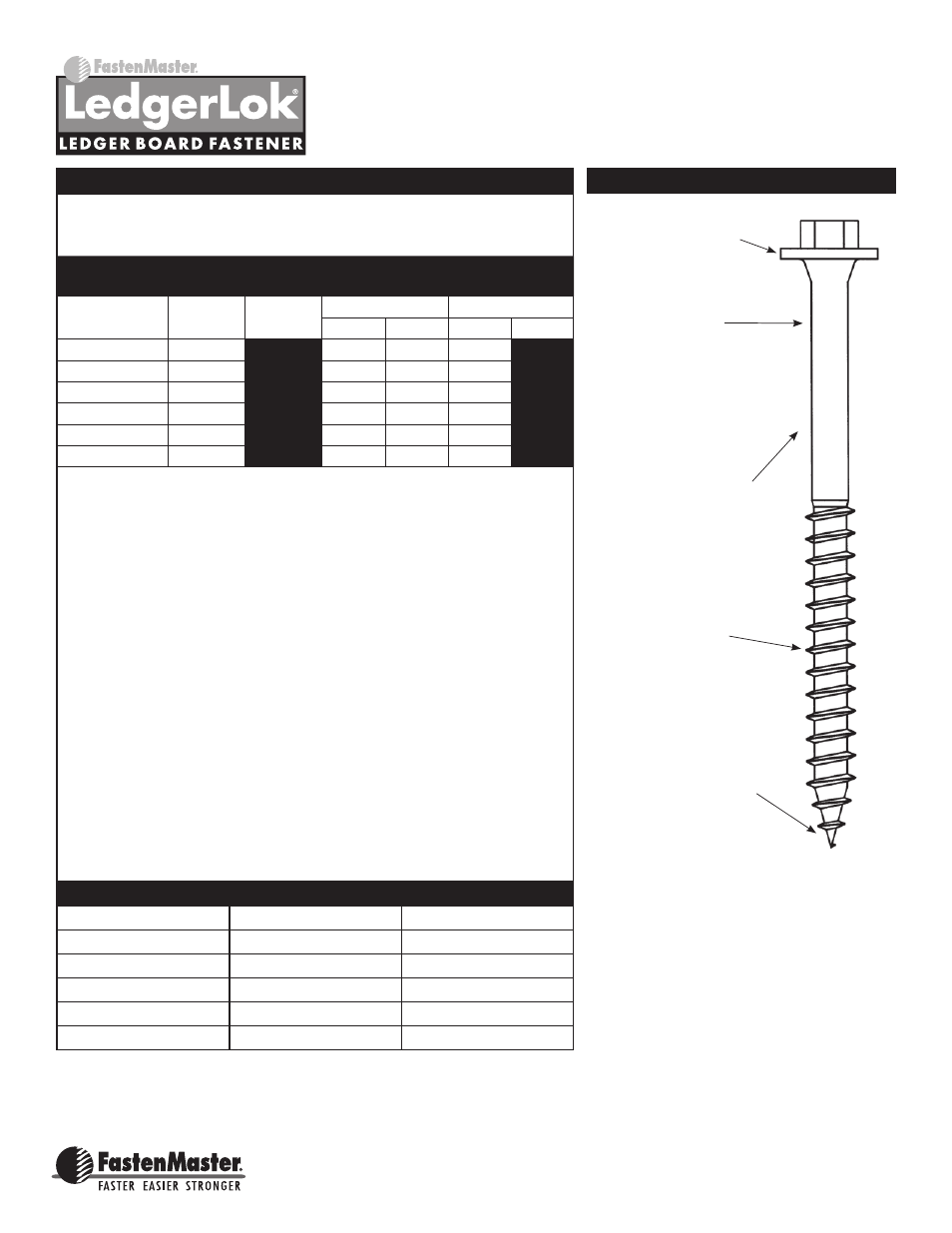

5

⁄

16

" hex

with oversized

washer head

Made oF heat

treated steeL For

draMatiCaLLY

iNCreased

streNGth aNd

drivaBiLitY

MULti-Coated

For GUaraNteed

CorrosioN

ProteCtioN.

aCQ aPProved

sUPer-sized

threads For

iNCreased hoLdiNG

Power

GiMLet PoiNt For

Fast driLLiNG

FMLLSHEET

(0211)

FASTENMASTER, INC., 153 BOWLES ROAD, AGAWAM, MA 01001

800.518.3569 WWW.FASTENMASTER.COM

FastenMaster

®

and LedgerLok

®

are trademarks of OMG, Inc. Copyright © 2011 OMG, Inc. All rights reserved.

INSTALLATION PROCEDURE

LedgerLok should be installed using a high torque,

1

⁄

2

" variable speed drill (at least 18V if cordless).

Choose the proper length LedgerLok so that threads fully engage the main member (i.e., rim joist). Bring

washer flush to side member – do not countersink.

* SCL=Structural Composite Lumber (LVL,PSL and LSL)

** Wood species identified typically have average specific gravity similar to the values shown on this table.

All design values based on 1

1

⁄

2

" side member thickness and penetration into main member as follows:

LedgerLok 2", Nails 10x diameter, Lags 8x diameter. Design values may be subject to adjustment factors

(section 10.3 in NDS) based on conditions existing during installation as well as those expected during

service life.

The lag screw and nail design values included in these tables are compiled directly from the 2005

National Design Specification for Wood Construction (2005 NDS).

For correct fastening patterns and complete installation procedures when attaching the deck ledger to

rim joist, consult our Deck Ledger to Rim Joist Technical Bulletin at www.FastenMaster.com. In some ledger

board connections, LedgerLok may not be a one-to-one replacement for

1

⁄

2

" lag screw patterns.

For use of LedgerLok in non-ledger applications, please consult a design professional for designing all

connections, which include the number and location of all fasteners to meet the national and local code

requirements.

Ledger Board attachment Comparative data

The statement “Faster, Easier, Stronger than

1

⁄

2

" lag screws” refers to the comparison of LedgerLok design

values in ICC-ES Report #1078 and

1

⁄

2

" lag screws as published in the current NDS.

For complete design values and engineering data, available through iCC-es, see report

esr #1078 at www.icc-es.org.

For technical assistance or questions regarding proper use of this fastener, please contact FastenMaster

Technical Support at 800.518.3569 or visit www.FastenMaster.com.

PRODUCT FEATURES

Lateral design values (in pounds per Fastener)

for single shear connections loaded perpendicular to grain

Wood

Specific

Gravity**

FastenMaster

LedgerLok

Nails

Lags

16D

20D

3

⁄

8

"

1

⁄

2

"

Red Oak

0.67

373

184

222

160

280

Southern Pine

0.55

290

154

185

140

230

Doug. Fir-L, SCL*

0.50

255

141

170

130

200

Doug. Fir-S

0.46

233

131

157

120

190

Hem. Fir

0.43

216

122

147

120

180

E. Spruce, W. Cedar

0.36

179

104

126

100

150

item #

screw Length

Quantity per Pack

FMLL358-12

3

5

⁄

8

"

12

FMLL005-12

5"

12

FMLL358-50

3

5

⁄

8

"

50

FMLL005-50

5"

50

FMLL358-250

3

5

⁄

8

"

250

FMLL005-250

5"

250