Installation procedure product features – FastenMaster TrussLOK-Z User Manual

Page 2

FMTSZSHEET

(0211)

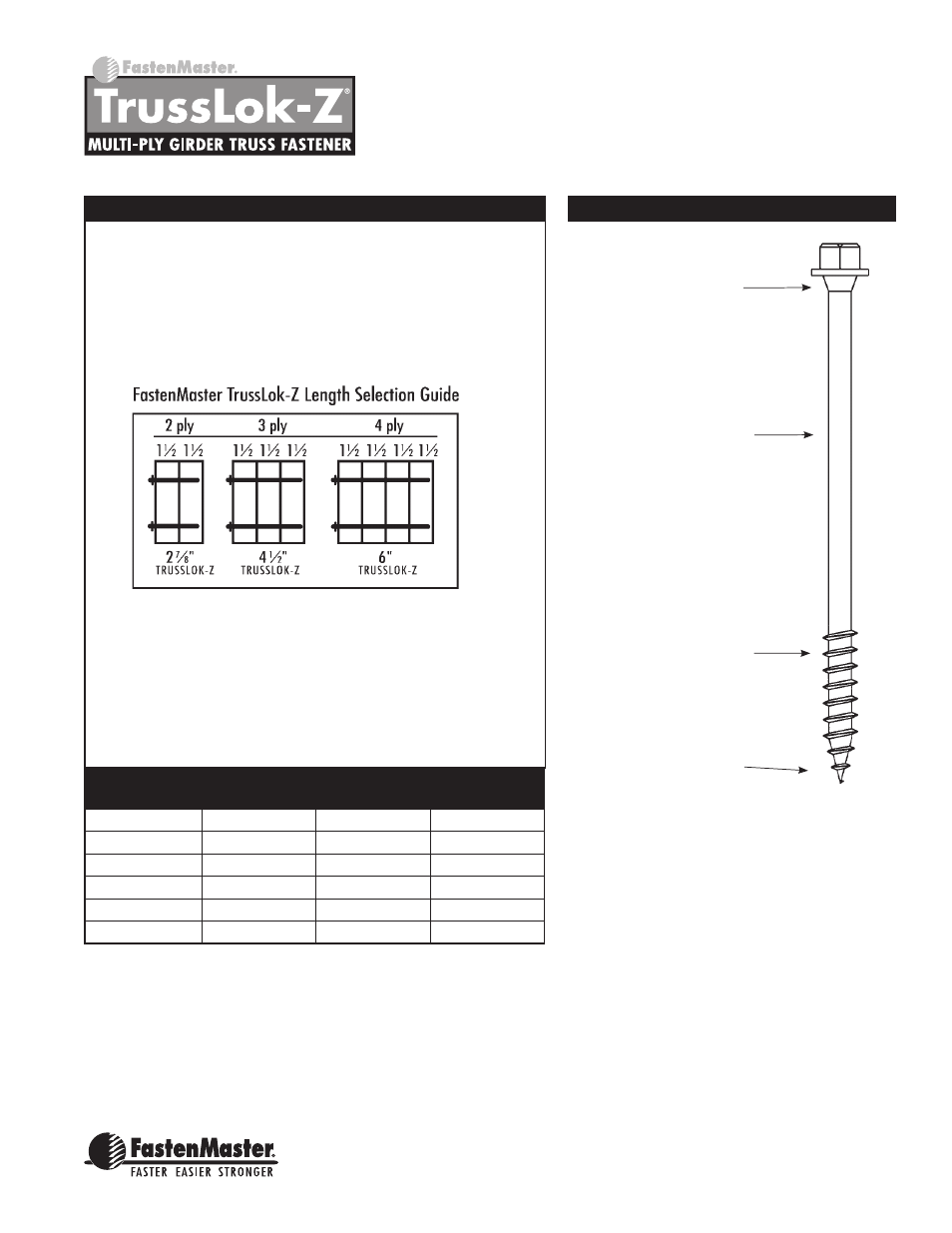

BuilT uP “chaMFEr”

uNdEr hEad For

addEd sTrENgTh

EPoxy coaTEd

wiTh aNTi-FricTioN

ToP coaT

corrEcT ThrEad

lENgTh. draws PliEs

TogEThEr wiThouT

“Board JacKiNg”

sharP giMlET PoiNT

For FasT drilliNg

FASTENMASTER, INC., 153 BOWLES ROAD, AGAWAM, MA 01001

800.518.3569 WWW.FASTENMASTER.COM

FastenMaster

®

and TrussLok-Z

®

are trademarks of OMG, Inc. Copyright ©2011 OMG, Inc. All rights reserved.

item #

Quantity

per Box

screw length

Threading

FMTSZ278-50

50

2

7

⁄

8

"

1

3

⁄

8

"

FMTSZ412-5

50

4

1

⁄

2

"

1

3

⁄

8

"

FMTSZ006-50

50

6"

1

3

⁄

8

"

FMTSZ278-500

500

2

7

⁄

8

"

1

3

⁄

8

"

FMTSZ412-250

250

4

1

⁄

2

"

1

3

⁄

8

"

FMTSZ006-250

250

6"

1

3

⁄

8

"

•

Install using a

1

⁄

2

" corded or 18 volt cordless drill.

•

Bring underside of washer-head flush with wood surface. Do not countersink.

•

Choose correct TrussLok-Z length. See below.

•

Always refer to truss manufacturer’s literature for proper fastening

pattern, design load information and additional fastener installation

requirements.

•

Maintain a minimum distance of 2" from any edge and 4" from end

of beam.

A design professional should be consulted when making critical connections

to ensure the proper number and location of all fasteners meet national and

local code requirements.

For complete design values and engineering data, available through ICC-ES,

see report ESR #1078 at www.icc-es.org.

For technical assistance or questions regarding proper use of this fastener,

please contact FastenMaster Technical Support at 800.518.3569 or visit

www.FastenMaster.com.

INSTALLATION PROCEDuRE

PRODuCT FEATuRES