Gel slider instructions, A. unpacking, B. assembly – C.B.S. Scientific GSL-1001 User Manual

Page 2: C. set-up of unit for sequencing gel casting, D. maintenance

Gel Slider Instructions

A. Unpacking

Please verify that your Gel Slider comes complete with the following:

• 2 side panels EACH with the following components:

a) 2 black leveling feet (4 total)

b) 1 attached adjustment panels marked with 1/8” and 3/16” held in place with 2 white thumb screws (2 total)

c) glass plate stop with nylon thumb screw (2 total)

• 2 slotted end assemblies each with 2 black thumb screws (4 total)

• 8 ea flathead screws

• 8ea white spring clamps

• Bubble level

B. Assembly

1. Place on level surface

2. Using a phillip’s head screwdriver screw cross bars

into side panels with the 8 flathead screws as shown

in figure 1.

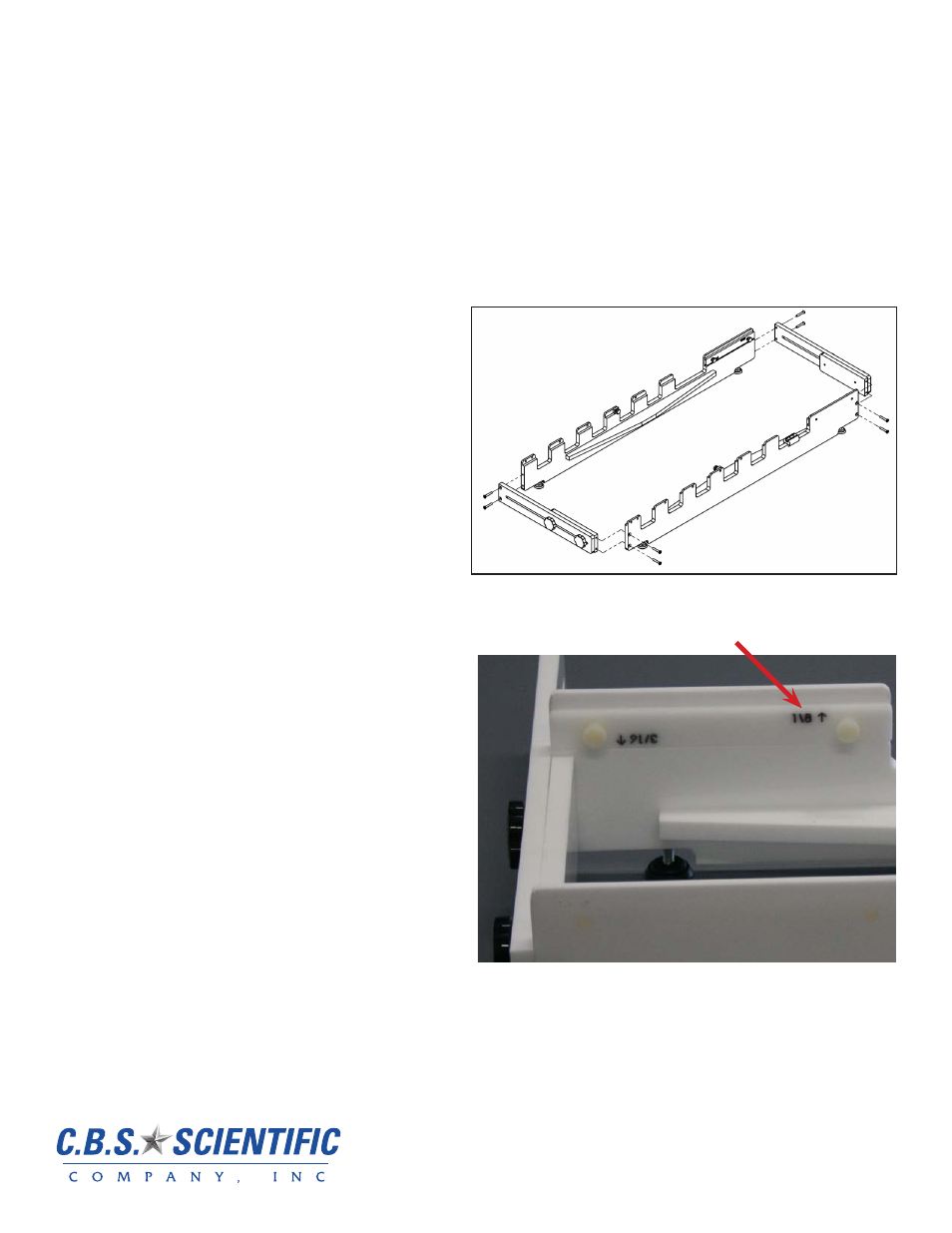

C. Set-up of Unit for Sequencing Gel Casting

1. Side panels with black numbers depicting back plate

thickness must be screwed in so either the 1/8”

or 3/16” arrow points up. (in photo at right the

correct position for a back plate width of 1/8” is

shown.). This important step assures there is the

proper offset on your glass plate assembly for opti-

mal gel casting. (Note: Gel Slider is shipped in the

3/16” position). If your back glass plate thickness

is 1/8”, unscrew white thumb screws and place 1/8”

arrow pointing up and re-tighten screws (as shown

by red arrow). If your back glass plate is 3/16”

unscrew white thumb screws and place 3/16” arrow

pointing up.

2. Level Gel Slider by using level provided and adjust-

ing leveling feet.

D. Maintenance

1. Keep Gel Slider clean by rinsing with de-ionized water.

figure 1.

P h o n e : ( 8 5 8 ) 7 5 5 - 4 9 5 9 U S T o l l F r e e : ( 8 0 0 ) 2 4 3 - 4 9 5 9

w w w . c b s s c i e n t i f i c . c o m