Enclosures, Enclosure construction, Edx -6- edx -5 – Bravox Linha EDX User Manual

Page 7: Vb w d h, Sealed enclosures

ENCLOSURES

The EDX12D subwoofer was specifically designed and built to be used in professional and competition

sound systems. For competition (SPL) installations, where maximum SPL is the goal, we recommend the use of

a vented enclosure. For professional installations, where a high quality of reproduction is a must, a closed box is

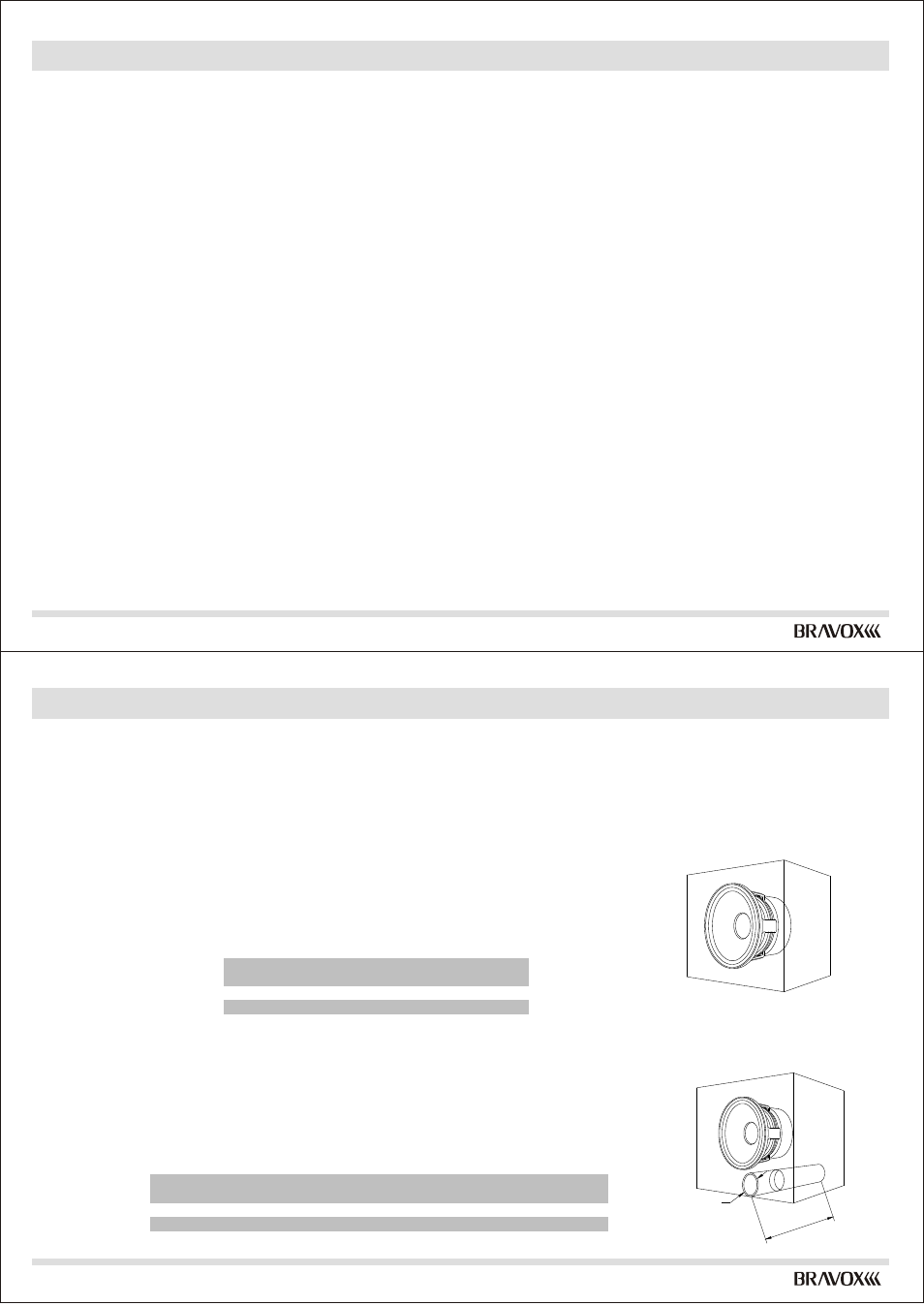

VENTED ENCLOSURES

Vented enclosures are not air-tight and incorporate an additional opening known as a

port or vent, which is generally fabricated from either plastic or cardboard tubing.

The port augments the sound coming out of the woofer and is in most cases capable

of going lower in frequency than the same woofer in a sealed box. Even though

vented enclosures are not air-tight, you should follow the same procedure as with

sealed boxes and glue and screw together all joints.

Vb

W

D

H

SEALED ENCLOSURES

This enclosure is made up of a totally closed, air-tight box. This type of enclosure gives

excellent, tight bass response, as well as providing an effective control of loudspeaker

excursion, maintaining it within reasonable limits and generally providing lower distortion

and very high volume levels. If you build your own enclosure, BRAVOX recommends that

you glue and screw all joints using enough glue to ensure that all joints are air-tight.

Vb

D

V

L

V

P

L

A

Internal Dimensions (mm - in) Duto

Model

Vb

(lts - ft3)

W

H

D

Dv (mm)

Lv (mm)

EDX12D-2

50 - 1.76 335 – 13.1 330 – 12.8 500 – 19.5

100

450

EDX12D-4

60 - 2.12 350 – 13.6 350 – 13.6 535 – 21

100

460

Internal Dimensions (mm - in)

Model

Vb

(lts - ft3)

W

H

D

EDX12D-2

20 - 0.7 310 - 12.1 310 - 12.1 340 – 13.3

EDX12D-4

28 - 1

310 – 12.1 310 – 12.1 270 – 10.5

ENCLOSURE CONSTRUCTION

The dimensions shown in above drawings are intended as a guideline and specific dimensions

(HxWxD) may be changed provided the internal volume of the enclosure is maintained and a suitable front

baffle is provided for driver and port. For best performance the walls of the enclosure should be rigid and not

vibrate as a result of the internal pressures generated by the loudspeakers. BRAVOX recommends

constructing enclosures from medium-density fiberboard (MDF) with a minimum thickness of 1”. In larger

enclosures over 1 cubic foot, internal bracing that joins opposite walls can be incorporated and the final

enclosure should be as rigid as possible. All joints should be glued and fastened with screws. Additionally,

internal joints can be covered with a small bead of silicone adhesive to ensure that the enclosure is completely

air-tight. Drivers should be fastened to the enclosure with self-threading screws with adequate length and

diameter, utilizing all the mounting holes in the frame. To avoid air leakage, a foam rubber gasket or similar

sealing method should be applied between the loudspeaker and the enclosure. The external surface of the

enclosure may be painted or fabric-covered, to suit the consumer.

Since low frequency sounds are not directional, subwoofer enclosures can generally be placed

anywhere within the car, without compromising stereo imaging. While the trunk is the most obvious location,

locating them behind the seats is another possibility. However, different placement locations of subwoofer

enclosures can sometimes influence the overall quality of bass/midbass response. As interior acoustics are

different for each vehicle, you may wish to experiment with various mounting locations before permanently

mounting the woofer.

EDX

-6-

EDX

-5-