BLACKHAWK! RIFLE COMPSTOCK User Manual

Page 5

www.BLACKHAWK.com

©BLACKHAWK! Products Group

™

NORFOLK, VA U.S.A. 1.800.694.5263

www.BLACKHAWK.com

©BLACKHAWK! Products Group

™

NORFOLK, VA U.S.A. 1.800.694.5263

Installation Instructions Continued

Special Instructions

Page 3

Page 4

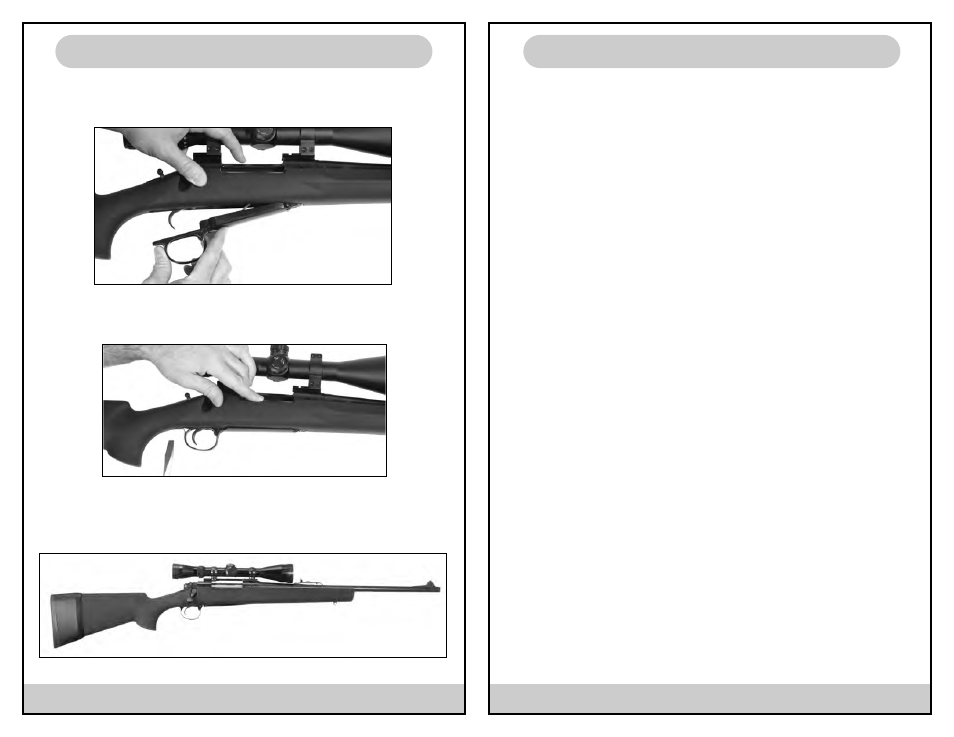

4. Reinstall trigger guard and hinged magazine floor plate assembly. (Fig. 4) Note: It is crucial that

the trigger guard and hinged magazine floor plate assembly is properly seated in the stock prior

to final installation and torquing of bolts.

5. While holding the trigger guard and hinged magazine floor plate assembly in position, reinstall

the two stock bolts removed in Step 1. (Fig. 5) Note: Take extra precaution not to cross thread

bolts. Floor plate should open and close easily.

6. Reinstall action bolt into receiver.

7. Installation of Rifle CompStock is now complete (Fig. 6). Prior to using rifle, verify correct instal-

lation of stock by checking function of action bolt, safety, magazine follower and floor plate.

SPECIAL INSTRUCTIONS FOR REMINGTON 700 RIFLES

To maximize the accuracy potential of your Remington 700, this stock is designed to "free Float"

the barrel and register tightly against the sides of the recoil lug. Because of slight angular varia-

tions in the recoil lug's location in each individual rifle, it can cause the barrel to contact one side

of the barrel channel. This can be left alone and the rifle will operate properly with no modifica-

tions. Some rifles will not need adjustment, if the barrel naturally centers itself. If the barrel does

not self center, and you desire to center the barrel, it is necessary to slightly rotate the recoil lug

to correctly float the barrel. To alleviate the barrel contact with the stock perform the following

steps.

1. UNLOAD THE RIFLE and remove the bolt.

2. With a pencil, mark the starting orientation between the barrel lug and action.

3. Lay the action on a solid padded surface, while holding the barrel firmly in the weak

hand.

4. With a soft medium sized brass hammer, strike the bottom corner of the recoil lug in the

opposite direction you want the barrel to float in the stock. The recoil lug is a separate

piece of steel held tightly between the barrel and the action; it will rotate. Only a very

small amount of movement is necessary and can be observed by the pencil mark.

5. Keep making small adjustments while checking the fit until the barrel centers when the

floor plate is bolted tightly to the rifle.

SPECIAL INSTRUCTIONS FOR WINCHESTER MODEL 70 RIFLES

To maximize the accuracy potential of your Model 70, this stock is designed to free float the bar-

rel. Due to slight variations in manufacturing of each individual rifle, the barrel may not center

itself in the stock and may even contact one side of the barrel channel. The rifle will function prop-

erly in this condition and most rifles will self-center. If the barrel does not self-center, and you

desire optimum accuracy, it is necessary to shim one side of the recoil lug to correctly float the

barrel. The recoil lug is the solid rectangular portion of the rifle actions directly forward and below

the front action screw hole, right behind the barrel. The lug should be shimmed on the same side

the contact occurs. Layers of adhesive tape applied to the side of the recoil lug worked well to

center the barrel. Usually no more than .005 to .01 shim is all that is necessary to center the bar-

rel.

NOTE: If you do not feel confident, seek the services of a competent gunsmith to perform this

adjustment for you. Provide these directions as a reference for your gunsmith.

NOTE: Another acceptable method is to carve out the recoil lug pocket in the stock and bed it with

a suitable bedding compound.

NOTE: The rifle will operate properly without any modification to either the stock or rifle.

Fig. 4

Fig. 5

Fig. 6