Troubleshooting analysis – Autoquip FREIGHTLIFT FLH User Manual

Page 97

97

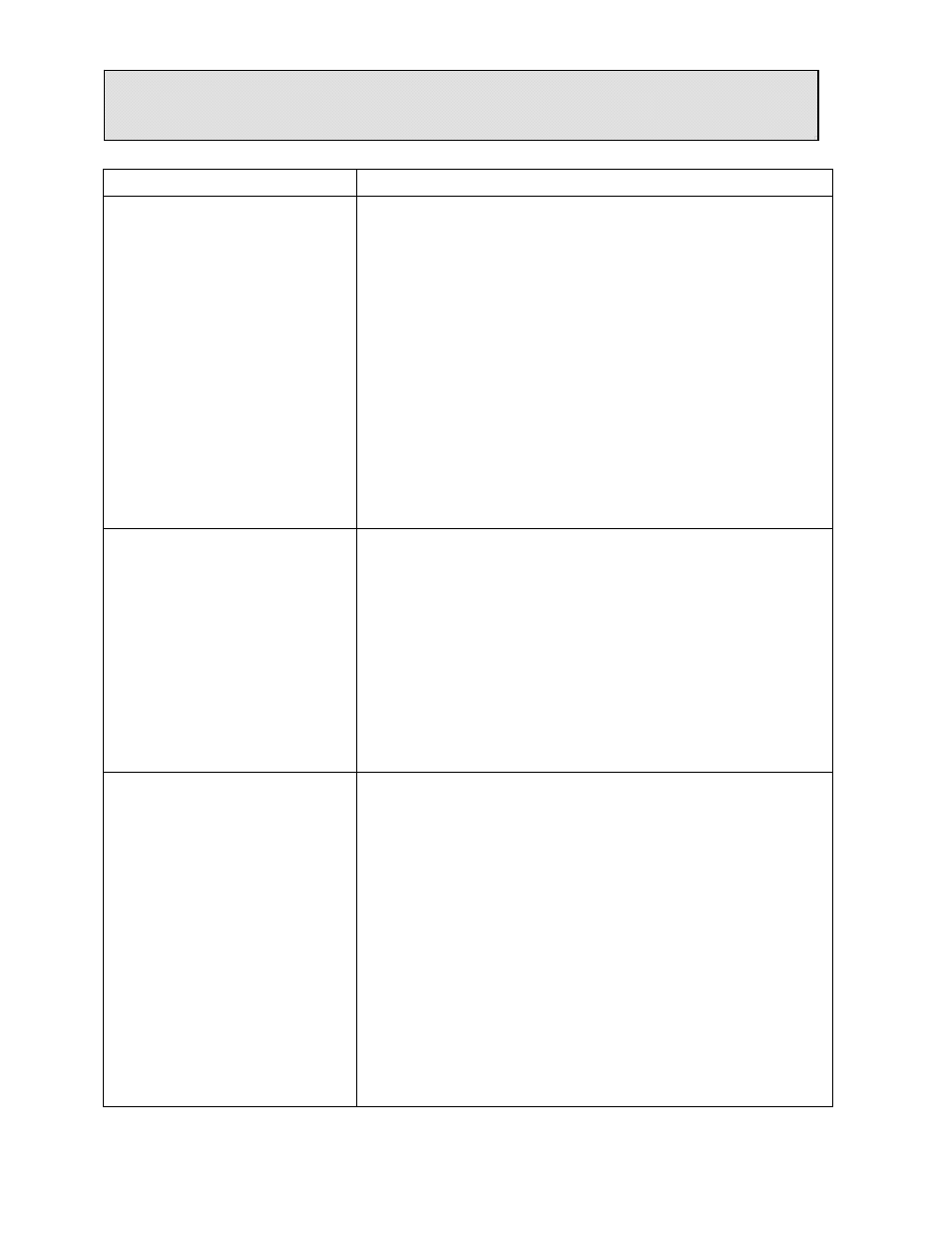

PROBLEM

POSSIBLE CAUSE AND SOLUTION

Unit operates in a “spongy”

or jerky fashion.

The load may exceed the stated capacity of the unit.

Overloading causes the pressure switch valve to

activate and deactivate if the “UP” button is

depressed. (Motor may start and stop if this condition

exists.) Remove the excess load.

The hydraulic system may have air in it. The unit

requires bleeding.

Check for oil starvation.

The rollers may be binding. Check and repair.

The platform carriage may be binding in the guide

ways. Check and repair.

The cylinder may be binding internally or externally.

Check and repair.

The pressure switch may be turning the motor on

and off. Check and repair.

The Freightlift lowers too

slowly with a load.

Check for a pinched hose or tubing.

The “DOWN” valve may be malfunctioning. Check

and replace control valve.

The “DOWN” valve solenoid mounting is loose,

preventing the valve from opening completely.

Check and repair.

Oil is extremely heavy for the application, or low

temperature is causing a thickening of the oil.

The “DOWN” valve solenoid may be weak and not

pulling in completely (it will usually “chatter”). Check

the control voltage. Check and repair or replace.

Freightlift raises, then

lowers back slowly.

The “DOWN” solenoid valve may be energized in the

“OPEN” position. Remove the solenoid coil and

recheck. If the lift does not hold with the solenoid

coil removed, replace the down valve cartridge.

The hydraulic cylinder rod seal may be leaking.

Check to see if there is hydraulic oil running down

the outside of the cylinder barrels at the rod end.

Repair as necessary. (NOTE: a small amount of oil

at the bottom of the rod is normal and desirable for

proper lubrication of the cylinder. A leak would

cause oil to flow from the rod area when the lift is in

the raised position.)

Check valve in the pump or Detatrol may be

contaminated or defective. Repair or replace.

TROUBLESHOOTING ANALYSIS