Troubleshooting analysis – Autoquip SPIRALIFT SCISSORS LIFT User Manual

Page 27

27

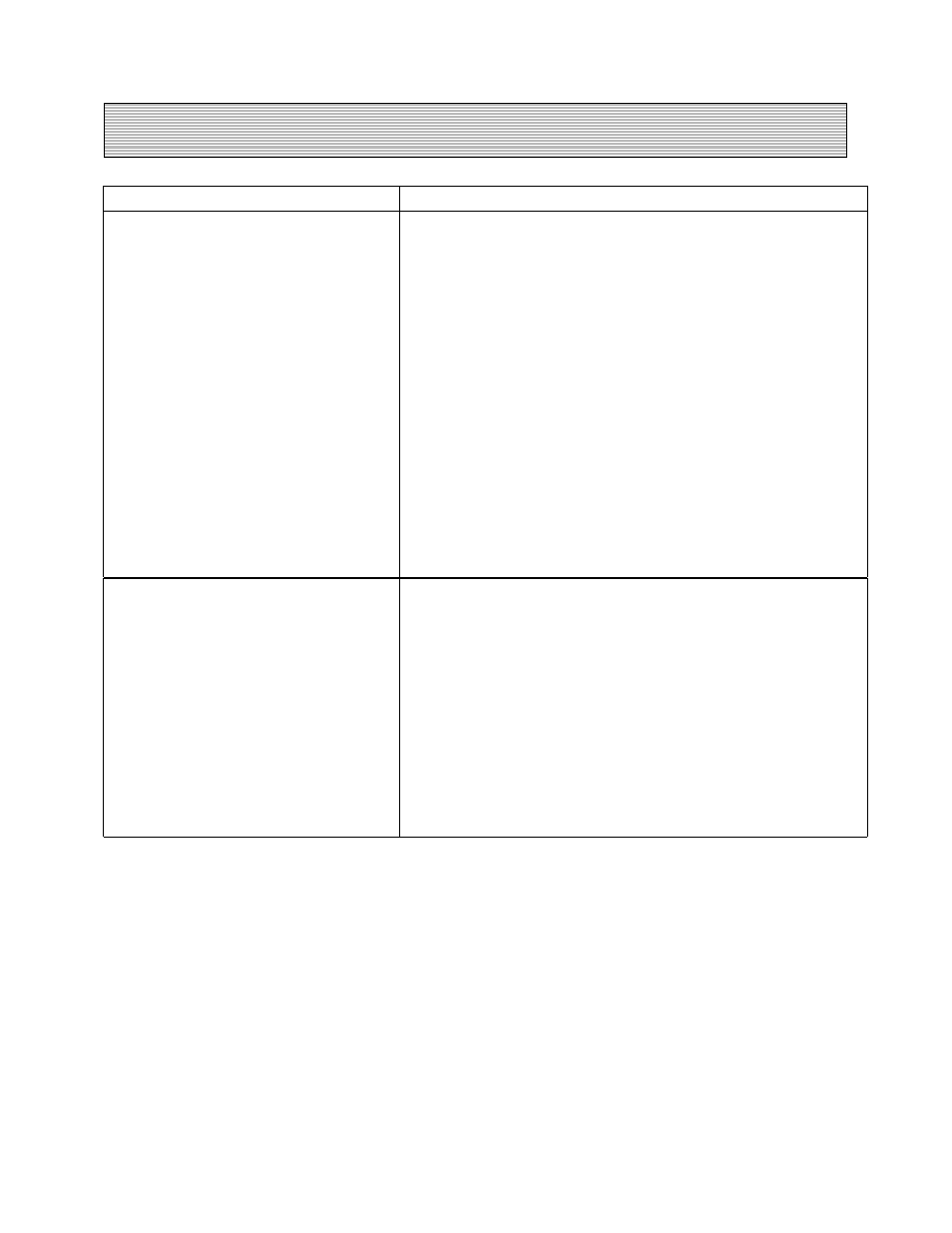

One of the driving belts on the

drive unit is broken.

•

If at any time one of the driving belts breaks

loose, the platform movement will stop

automatically. A proximity switch senses the

broken belt and the platform will not move until

this belt is replaced. Block the platform in its

position. Remove the load. Verify that the

platform won’t move. Remove the belt guard

and replace both belts. If the column has been

lowered away from the top platform, re-insert

the top plate of the column into its pocket

according to previous steps described.

PROBLEM

POSSIBLE CAUSE AND SOLUTION

Platform jams during downward

stroke. Stop the lift immediately if

it has not already stopped

automatically (continued from

previous page).

•

The column has lost its integrity (i.e., the

vertical band has come out of the grove in the

horizontal band.) Block the platform in its

position. Remove the load. Feed the two

bands back into their respective storage

position by rotating the head of the column. If

this is difficult, remove the retaining screws at

the top end of the vertical band and then feed

the two bands back down individually. When

the horizontal band and the head assembly are

at the bottom and the vertical band is in the

magazine, re-attach the vertical band to the

head assembly and reinsert the retaining

screws. Rotate the column assembly up, by

hand, by rotating the top plate slowly. Proceed

with the corrective measures described above.

TROUBLESHOOTING ANALYSIS