General maintenance, Caution – Autoquip SPIRALIFT SCISSORS LIFT User Manual

Page 21

21

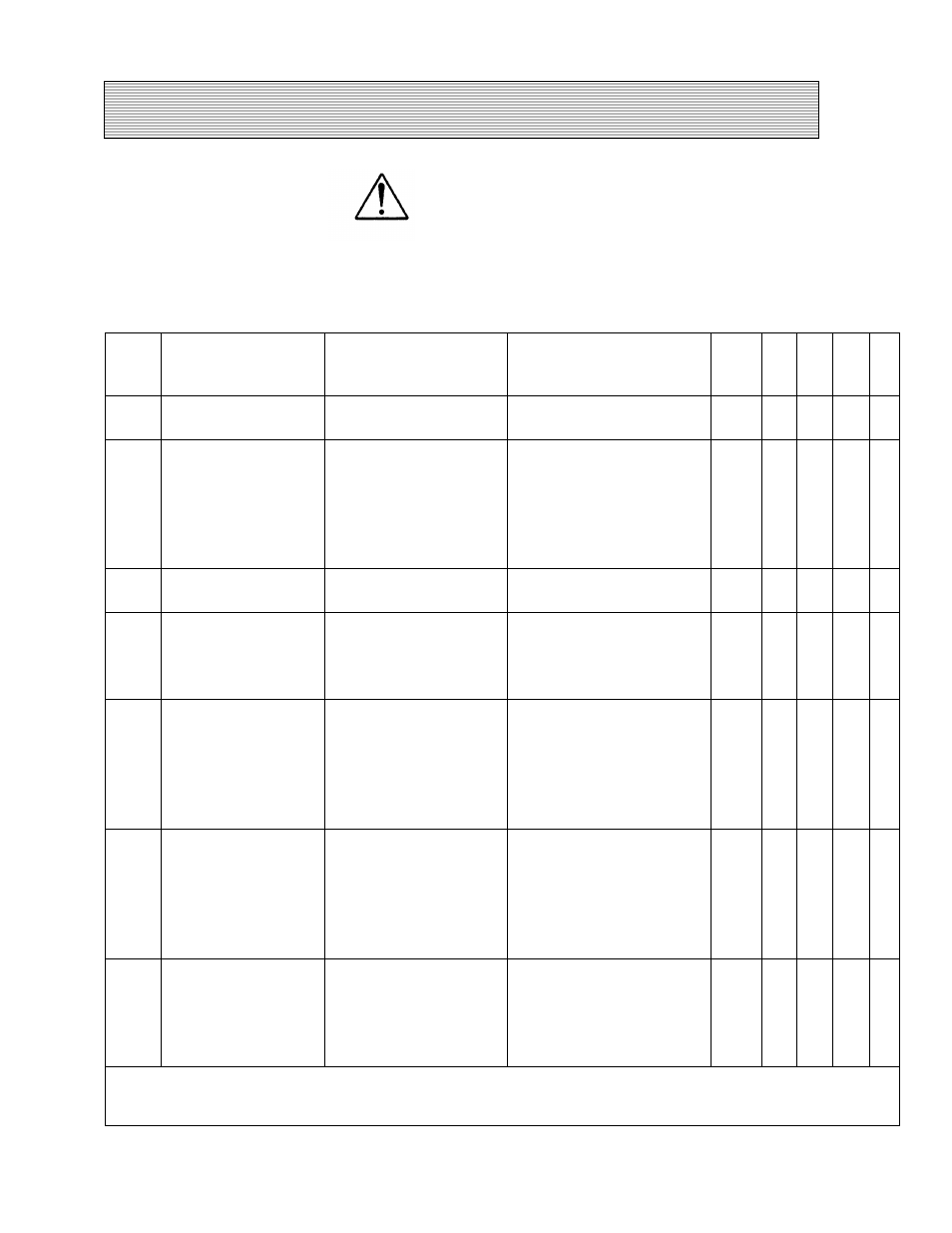

CAUTION!

At no time should the scissor table be raised by the platform.

Item

Description

Maintenance

Task

Corrective Action

O/C

D

M

S

A

1

Spiralift™ drive

chains

Check for excess

slack and alignment

Retighten or realign;

re-lubricate.

X

2

Spiralift™

gearbox

Check the oil level

of the gearbox

Remove the top and

side oil plug; add oil in

the top opening until

oil starts to flow from

the side opening. Re-

install plugs.

X

X

3

Drive belts

Check condition

and tightness

Retighten or replace

as required.

X

4

Driving pinion of

the gearbox and

ring gear on the

Spiralift™

Check lubrication of

the gears

Clean and re-lubricate

both gears.

X

X

5

Vertical band and

horizontal band

of the Spiralift™

Check for rust or

accumulation of dirt

on the bands

Clean and wipe the

bands and spray gear

oil on the bands, with

no excess, as they roll

up into the column

structure.

X

X

6

Inserting system

Check for loose

screws on the

vertical band

inserting system

and on the vertical

band retainer.

Tighten if required.

Caution: All fasteners

are assembled with

“loctite”.

X

X

7

Vertical band

magazine

Make sure

magazine is

spinning freely with

no friction due to

dirt in the bearing.

Clean and lubricate

magazine ball bearing

system.

X

X

Legend: O/C = On condition (when item becomes unserviceable; D = Daily; M = Monthly;

S = Semi-annually; A = Annually. If over one year, maintenance interval will be specified.

GENERAL MAINTENANCE