APG PT-L10-C user manual User Manual

Page 4

PT-L10-C

Rev. A3, 10/08

4

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • [email protected]

•

Instructions

All units are factory calibrated prior to shipment.

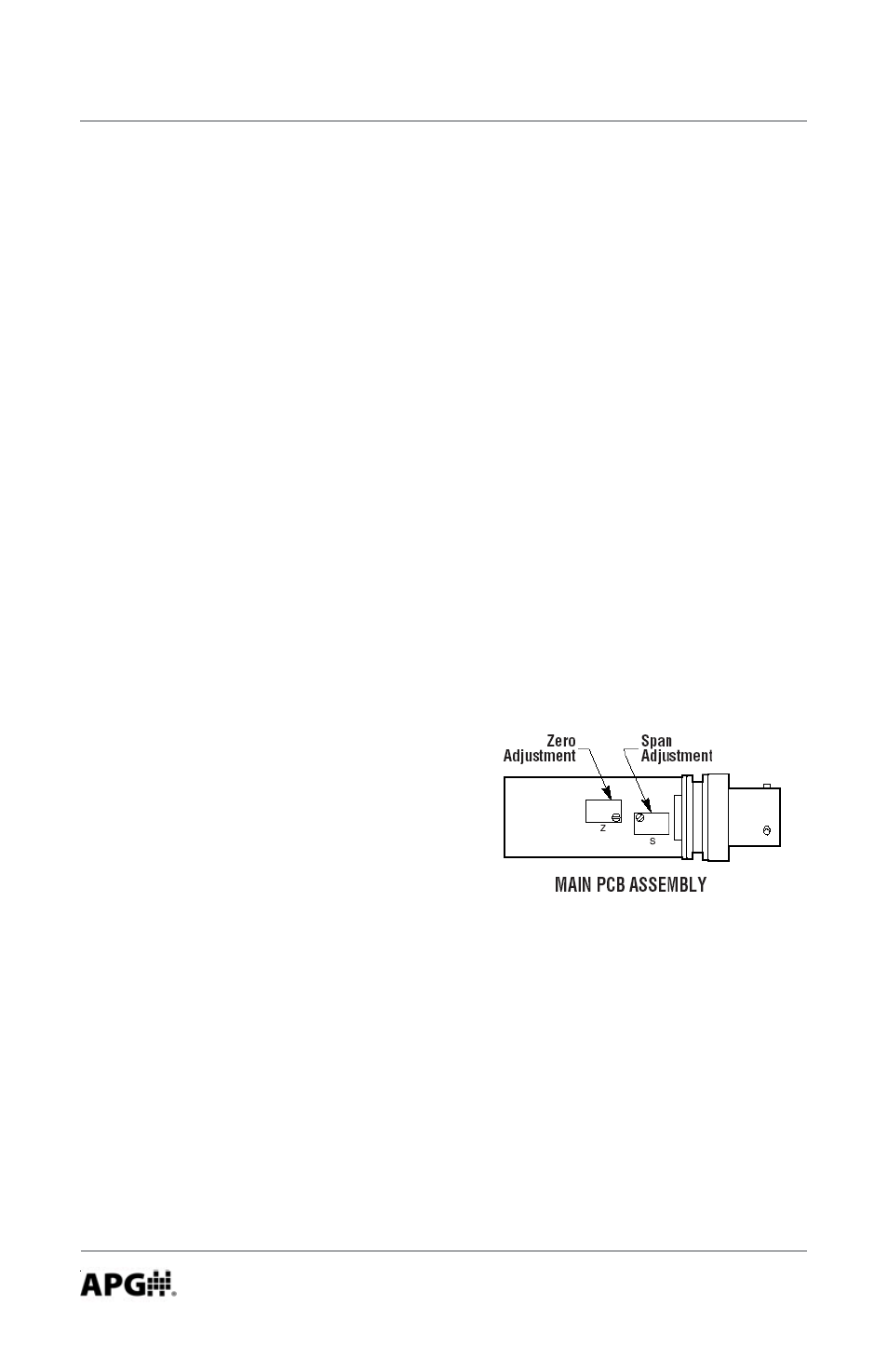

1. Zero Trimming

If it becomes necessary to re-adjust “zero”, this can be accomplished by

adjusting the trimpot marked “Z”. An ideal zero is indicated by an output of

0 VDC.

A. Remove the knurled nut. If your transducer does not have a knurled nut,

your transducer can not be field adjusted. You can return the transducer

to the factory for repair and/or adjustment.

B. Carefully remove the connector or pigtail from the body of the transducer

and pull it all the way out so that the amplifier board is exposed. Do not

over extend the ribbon cable that attaches the amplifier board to the

sensor.

C. Reconnect the device and have access to a method of monitoring the

output of the transducer.

D. Ensure that the transducer is at 0 psig or 0 psia (vacuum if absolute)

E. Using a jewelers screwdriver or a suitable instrument, adjust the “Z” pot

until you have 0 VDC output. Do not

make changes to the Span

adjustment (the “S” pot to the right

of the push button) as part of the zero

trimming. The Span should only be

changed as part of the re-calibration

of a transducer with a known pressure

source.

2. Re-calibration

This procedure requires a known pressure source of at least ±0.1% accuracy

in order to fully utilize the accuracy potential of the transducer. (If not available,

you can return it to the factory for re-calibration.)

Procedure:

A. Ensure that the transducer is at 0 psig or 0 psia (vacuum if absolute), and

adjust zero as per instructions in #1.

B. Apply full scale pressure to the pressure port and adjust the span (“S”)

pot until full scale signal of 10 VDC is reached.