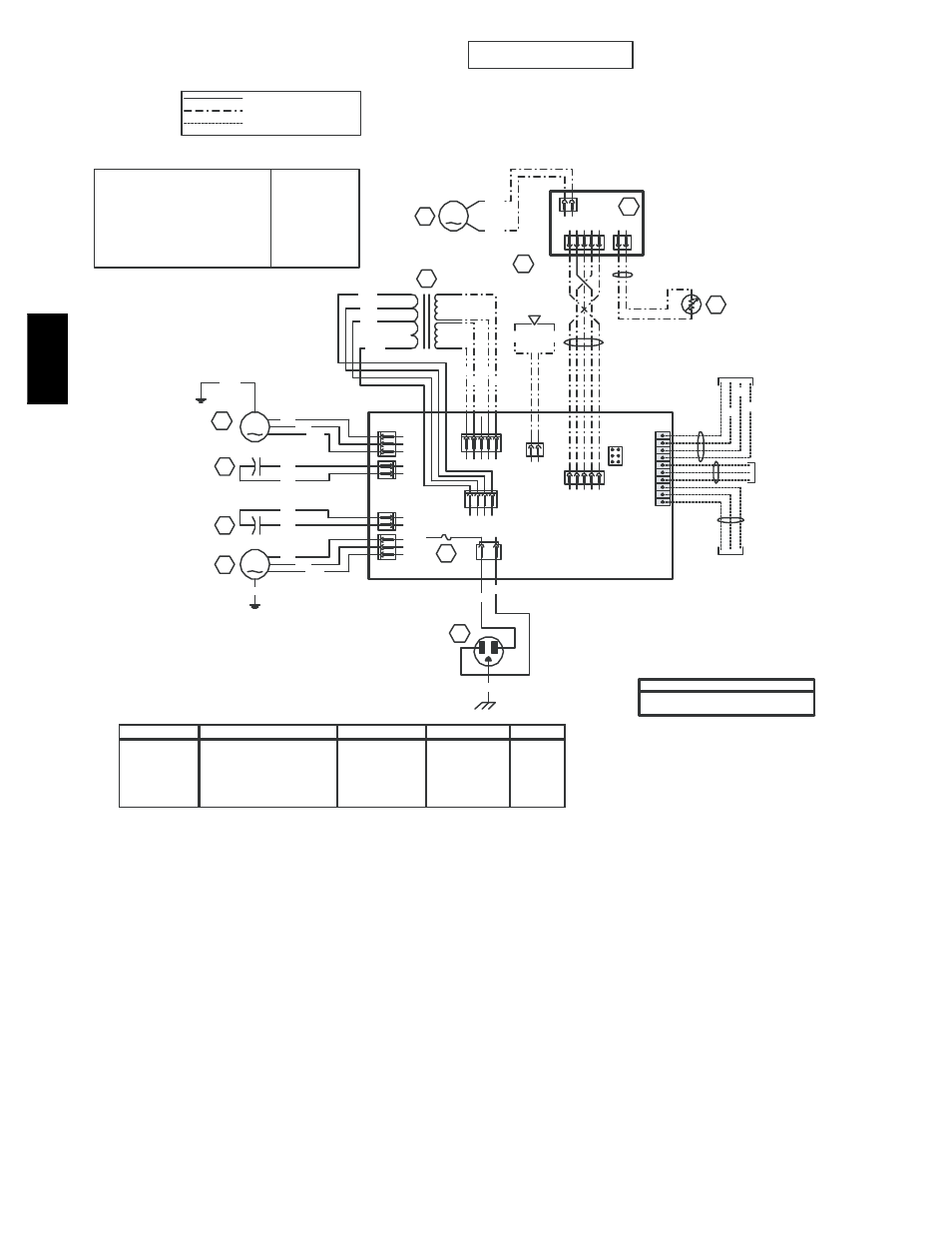

Connection diagram, Er v /hr v, Fig. 17 -- erv / hrv wiring diagram – Bryant Energy/Heat Recovery Ventilator ERVBBSVA1100 User Manual

Page 12

12

M1

T1

R1

Field wiring

remote control

(see notes 3, 4)

120V, 60Hz

W1

F1

J5

J7

J6

J4

ELECTRONIC ASSEMBLY

1

2

3

1

2

1

2

1

2

3

1

2

3

4

1 2

1 2 3 4 5

1

2

3

4

5

J8

J9

J11

J10

1

2

J12

J13

J14

10

9

8

7

6

5

4

3

2

1

YEL

RED

GRN

BLK

M2

C1

C2

BLK

BLU

BRN

BLK

BLK

BLK

BLK

BLK

BLU

BRN

24V class 2

9.5V

class 2

BLK

WHT

BRN

BRN

Y

Y

GRN

See note 1

120V

90V

68V

neutral

BLK

BLU

RED

WHT

Door interlock

switch

(magnetically

actuated reed

switch)

WHT

WHT

Exhaust fan motor

Exhaust fan motor

capacitor

Supply fan motor

capacitor

Supply fan motor

GRN

GRN

1

2

3

4

5

1

2

1 2

J3

J2

J1

to

M3

Damper motor

BLK

BLK

Override switch

(optional; see notes

3, 4)

Furnace blower interlock

J14-1 : NO Connect to R at Furnace / Fan Coil

J14-2 : COM Connect to G at Furnace / Fan Coil

J14-3 : NC Connect to G at Thermostat

(see notes 3 , 5)

A2

DAMPER ELECTRONIC

ASSEMBLY

Defrost temperature

sensor

S1

ICP

CONNECTION DIAGRAM

Line voltage factory wiring

Class 2 low voltage factory wiring

Class 2 low voltage field wiring

COLOR CODE

BLK

BLACK

BLU

BLUE

BRN

BROWN

GRN

GREEN

GRY GRY

ORG

ORANGE

RED RED

WHT

WHITE

YEL

YELLOW

1. For continued fire protection, use specified UL

listed/CSA Certified line fuse.

2. If any of the original wire, as supplied, must be

replaced,

use the same equivalent wire.

3. Field wiring must comply with applicable codes,

ordinances and regulations.

4. Remote controls available. See instruction

manual. (class

2 circuit)

5. Furnace fan circuit must be class 2 circuit only.

MODELS

HRVCCSHA1100, HRVCCSVA1100,

ERVCCSHA1100, ERVCCSVA1100,

K5 K2 K3 K1

MODE

M1 "Supply"

M2 - "Exhaust"

DAMPER

0

0

0

0

OFF

OFF

OFF

Closed

1

0

1

1

Exchange low speed

LO

LO

Opened

1

1

1

1

Exchange high speed

HI

HI

Opened

1

1

1

0

Circulation high speed

HI

OFF

Closed

1

1

1

0

Defrost

HI

OFF

Closed

A07118

Fig. 17 -- ERV / HRV Wiring Diagram

ER

V

/HR

V