Bryant SINGLE PACKAGE ROOFTOP ELECTRIC COOLING/GAS HEATING UNITS 581A User Manual

Page 29

—29—

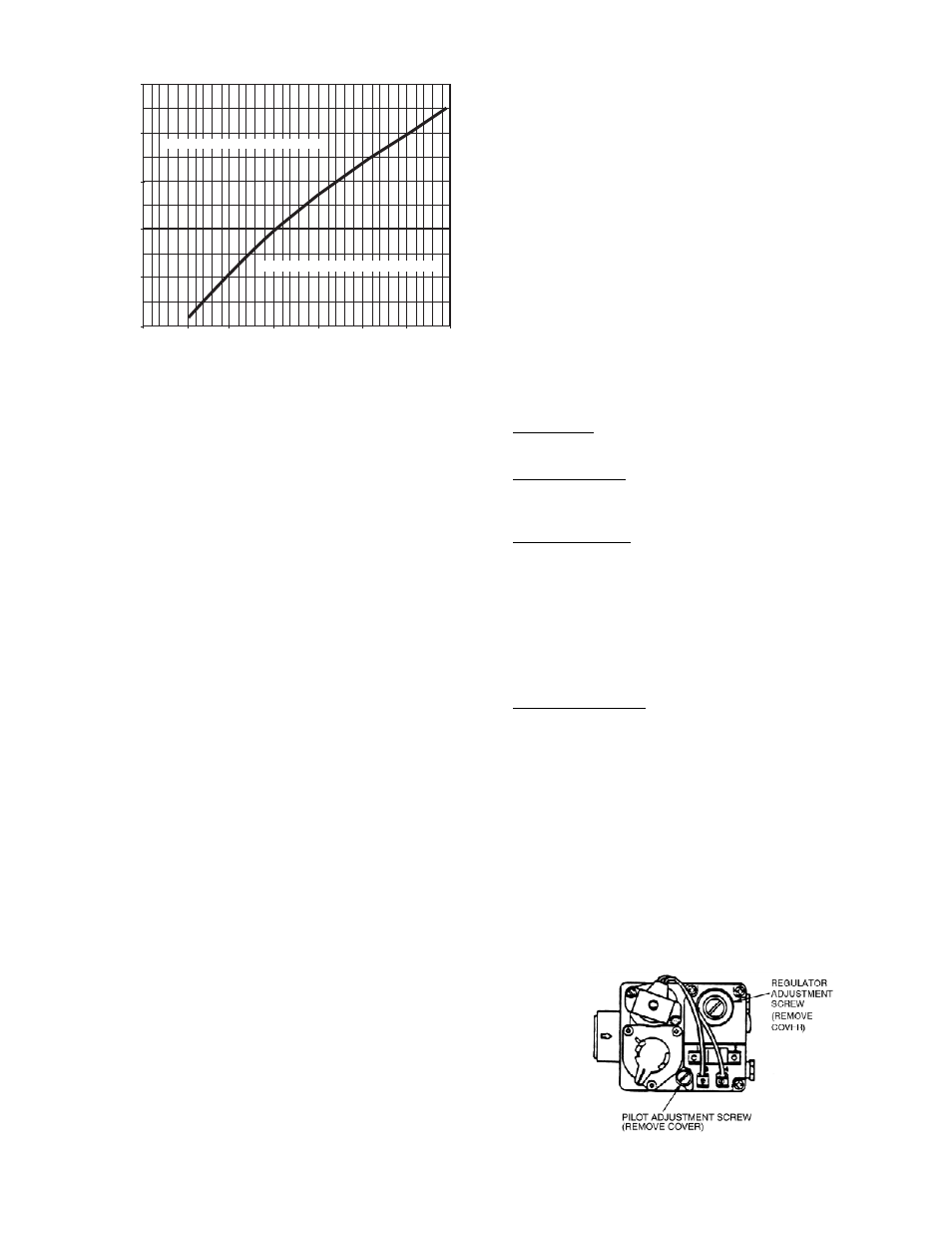

X. GAS VALVE ADJUSTMENT

A. Natural Gas

The gas valve opens and closes in response to the thermostat

or limit control.

When power is supplied to valve terminals D1 and C2, the

main valve opens to its preset position.

The regular factory setting is stamped on the valve body

(3.3 in. wg).

To adjust regulator:

1. Set thermostat at setting for no call for heat.

2. Turn main gas valve to OFF position.

3. Remove

1

/

8

-in. pipe plug from manifold or gas valve

pressure tap connection. Install a suitable pressure-

measuring device.

4. Set main gas valve to ON position.

5. Set thermostat at setting to call for heat.

6. Remove screw cap covering regulator adjustment

screw (See Fig. 36).

7. Turn adjustment screw clockwise to increase pres-

sure or counterclockwise to decrease pressure.

8. Once desired pressure is established, set thermostat

setting for no call for heat, turn off main gas valve,

remove pressure-measuring device, and replace

1

/

8

-in.

pipe plug and screw cap.

XI. MAIN BURNERS

For all applications, main burners are factory set and should

require no adjustment.

A. Main Burner Removal

1. Shut off (field-supplied) manual main gas valve.

2. Shut off power to unit.

3. Remove unit control box access panel, burner section

access panel, and center post (Fig. 4 and 5).

4. Disconnect gas piping from gas valve inlet.

5. Remove wires from gas valve.

6. Remove wires from rollout switch.

7. Remove sensor wire and ignitor cable from IGC

board.

8. Remove 2 screws securing manifold bracket to

basepan.

9. Remove 2 screws that hold the burner support plate

flange to the vestibule plate.

10. Lift burner assembly out of unit.

B. Cleaning and Adjustment

1. Remove burner rack from unit as described in Main

Burner Removal section above.

2. Inspect burners, and if dirty, remove burners from

rack.

3. Using a soft brush, clean burners and crossover port

as required.

4. Adjust spark gap. See Fig. 37.

5. Reinstall burners on rack.

6. Reinstall burner rack as described above.

XII. FILTER DRIER

Replace whenever refrigerant system is exposed to

atmosphere.

XIII. PROTECTIVE DEVICES

A. Compressor Protection

Overcurrent

Each compressor has internal line break motor protection.

Overtemperature

Each compressor has an internal protector to protect it

against excessively high discharge gas temperatures.

Crankcase Heater

The 581A units are equipped with a 70-watt crankcase

heater to prevent absorption of liquid refrigerant by oil in

the crankcase when the compressor is idle. The crankcase

heater is energized whenever there is main power to the unit

and the compressor is not energized.

IMPORTANT:

After prolonged shutdown or servicing, ener-

gize the crankcase heaters for 24 hours before starting the

compressors.

Compressor Lockout

If any of the safeties (high-pressure, low-pressure, freeze

protection thermostat, compressor internal thermostat) trip,

or if there is loss of power to the compressors, the cooling

lockout (CLO) will lock the compressors off. To reset, manu-

ally move the thermostat setting.

B. Evaporator Fan Motor Protection

On size 155 units, an internal protector with auto-reset is

included in the indoor fan motor as a protection against

overcurrent.

On size 180 and 240 units, a manual reset, calibrated trip,

magnetic circuit breaker protects against overcurrent. Do

not bypass connections or increase the size of the breaker to

correct trouble. Determine the cause and correct it before

resetting the breaker.

Fig. 35 — Cooling Charging Chart

50

40

100

150

200

250

300

350

400

60

80

100

120

140

ALL OUTDOOR FANS MUST BE OPERATING

LIQUID PRESSURE AT LIQUID VALVE (PSIG)

LIQUID

TEMPERA

TURE

A

T

LIQUID V

A

L

VE (DEG F)

BOTH CIRCUITS

REDUCE CHARGE IF BELOW CURVE

ADD CHARGE IF ABOVE CURVE

Fig. 36 — Gas Valve