4 replacing the wear liner, 5 unplugging the rotor, 6 unplugging the inlet hose – Echo DL10570 Owners Manual v.4 User Manual

Page 15

8 & 10 Inch Debris Loaders

11

SERVICE & MAINTENANCE

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE,

AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

WARNING

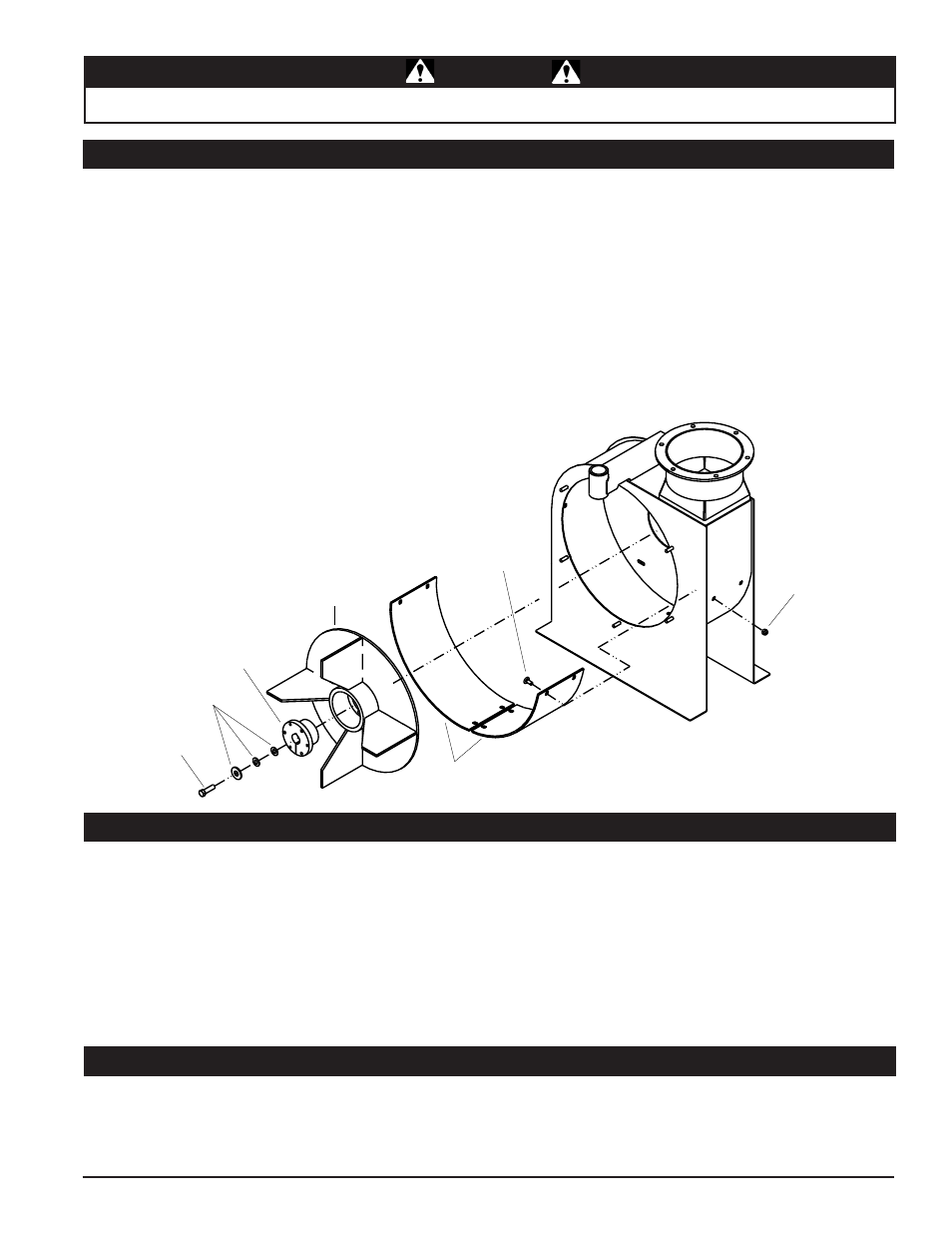

5.4 REPLACING THE WEAR LINER

The fan housing wear liners are replaceable on 390cc &

570cc engine models. To replace the wear liners:

1. Shut off engine and allow rotor to completely stop.

2. Remove the fan intake weldment from the fan

housing.

3. Remove the 7/16 x 1-1/2" bolt and washer from the end

of the engine crank shaft.

4. Remove the bushing and rotor from the engine crank

shaft.

5. From the outside of the debris loader housing, remove

eight 5/16" nylock nuts that hold the two wear liners.

WEAR

LINERS

ROTOR

BUSHING

7/16” x

1-1/2” BOLT

WASHERS

5/16” x 3/4”

CARRIAGE

BOLT

5/16”

NYLOCK NUT

The debris loader is designed to be used in fairly dry

conditions. Wet material, along with too much debris and

large sticks, can plug the rotor or hose. A plugged rotor

bogs down the engine and can possibly stop the engine if

the rotor is severely plugged. To clear the rotor:

1. Shut off engine and allow rotor to completely stop.

2. Remove spark plug wire.

3. Loosen the six 5/16" nuts that hold the intake weldment

to the debris loader frame.

5.5 UNPLUGGING THE ROTOR

1. If the hose becomes plugged during operation,

straightening the hose may dislodge the clog.

2. If straightening the hose does not work, shake the hose

in an up and down or side to side motion.

5.6 UNPLUGGING THE INLET HOSE

6. Remove the old wear liners and insert the new liners.

7. Install the new wear liners with eight 5/16 x 3/4" carriage

bolts and nylock nuts. Feed the carriage bolts from

inside the debris loader housing. Torque hardware to

17 ft-lbs.

8. Reinstall the bushing and rotor on the engine crank

shaft.

9. Reinstall the 7/16 x 1-1/2" bolt and washer to the engine

crank shaft. Torque to 50 ft-lbs.

10. Make sure approximately 1/4" clearance exists between

the fan housing and the rotor plate.

4. Turn the vacuum intake clockwise to remove it.

5. Check the hose for clogs and clear debris from the

rotor.

6. Turn the rotor by hand to verify it is unplugged.

7. Place the intake weldment over the six frame nuts and

turn it counterclockwise to set the studs in the weldment

notches. Tighten 5/16" nuts to 17 ft-lbs.

8. Reconnect spark plug wire and resume operation.

3. If the clog remains after performing the above two steps,

shut the engine off and wait for all moving parts to stop

moving. Then, remove the hose from the fan housing

and manually unplug the hose.