3 hydraulic feed operation (cont), 4 control arm operation, 5 safety bar ("s" models) – Echo 72928 Owners Manual v.6 User Manual

Page 19: Warning

9 INCH CHIPPER

17

CONTROLS AND OPERATION

5. As air is purged from the unit, the oil level in the res-

ervoir will drop and bubbles may appear in the fluid.

Refill the reservoir as necessary.

6. Run the unit in both directions for several minutes until

any remaining air is purged from the unit. Refill the

reservoir as necessary.

7. Check to make sure the feed roller stops when the

control arm is in the neutral position. Adjust the cable

clevis or anchor if the feed roller doesn't stop.

8. Shut down the engine, check for and correct any

fluid leaks, and check the reservoir level. Add fluid

if necessary. The hydrostatic pump is now ready for

operation.

Warning

Do not start engine unless pump is in neutral or detent

position on the cable.

Figure 3.3, Hydrostatic pump components

3.4 conTrol arm oPeraTion

1. Start the chipper engine. Bring the chipper up to op-

erating speed.

2. Engage the hydraulic feed by moving the control arm

as shown in Figure 3.4. In the forward direction, the

feed rate increases as the arm is moved.

3. Feed the branch (up to nine inches in diameter).

4. If the chipper jams, reverse the feed by moving the

control arm in the reverse direction. Remove the branch

and rotate it before inserting it into the chute again.

Feed Control

Lever

Forward

Reverse

Neutral

Figure 3.4, Control arm operation

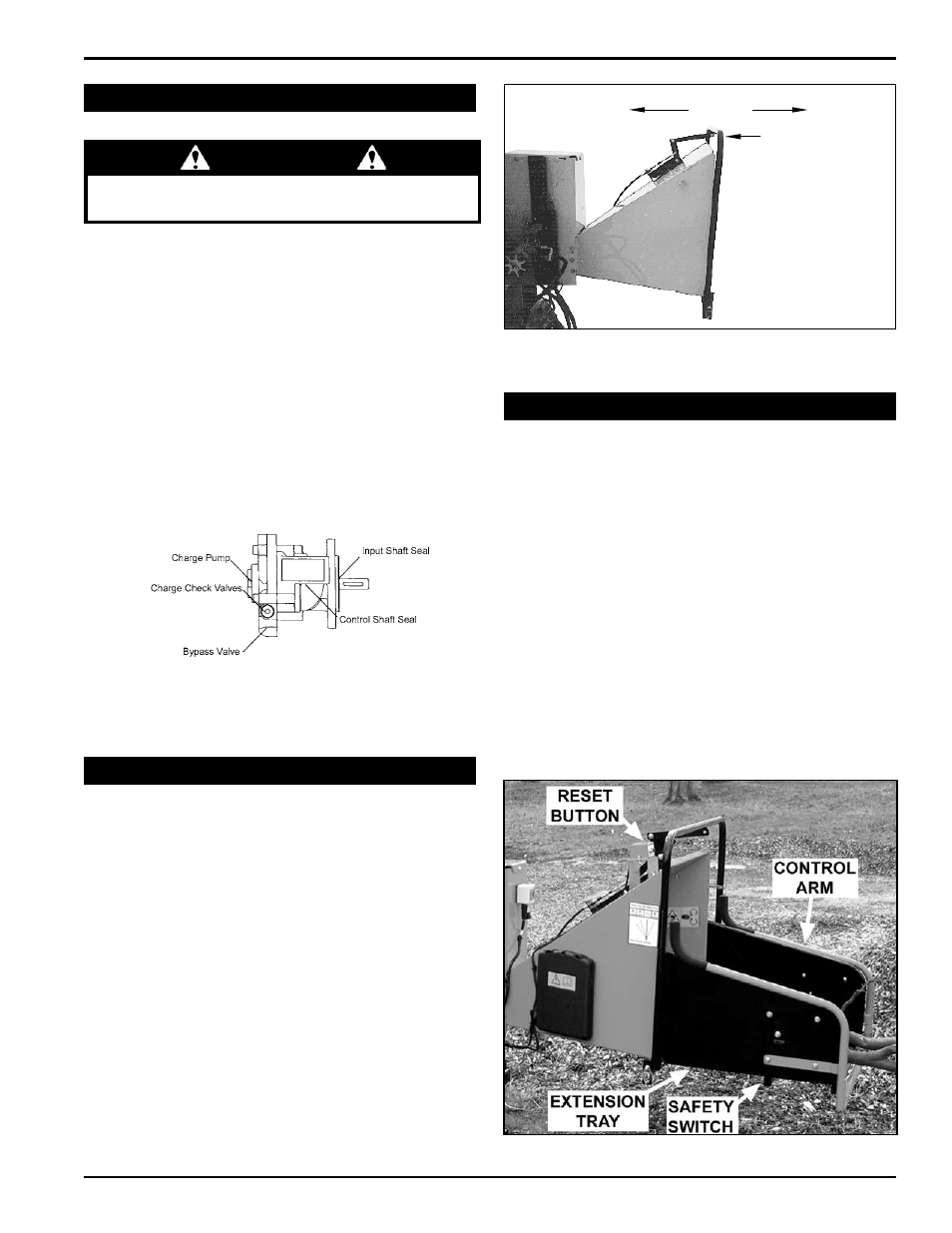

3.5 SafeTY bar ("S" modelS)

3.5.1 reSeTTing The chiPPer

The safety bar (See Figure 3.5) located along the chute

extension tray will stop the chipper when pushed in. The

reset button for this bar sits on top of the chipper chute.

When the safety bar has been activated, a red light will

come on signaling that the operator reset button will need

to be pushed before the feed roller will function. If false

trips occur, the reset button can be held in to override the

system. Upon start-up, the safety bar light will be on and

will need to be reset before the feed roller will operate.

3.5.2 locking in Travel PoSiTion

The safety bar will lock into travel position. Place the

extension tray in an upright position. Pushing the safety bar

down will lock the bar. To unlock, lower the extension tray

and push in on the safety bar. This will release the flange

and allow the safety bar to move freely.

Figure 3.5, Safety bar components ("S" models)

3.3 hYdraulic feed oPeraTion (conT).