Warning – Echo 74624 Owners Manual v.2 User Manual

Page 19

17

OPERATION

4.6 hYdraulic feed conTrol

the chipper is equipped with a pre-programmed hydraulic

feed control located under the control panel. the controller

monitors chipper rotor RPM, controls the feed roller, and

provides routine maintenance alerts.

the controller can be turned off with the switch located below

the control panel. If the controller becomes damaged, the

chipper will still run with the controller shut off, however all

of the controller functions will be disabled. the feed roller

will have to be controlled with the control arm.

The feed conTrol funcTions are furTher

deTailed beloW:

the controller monitors the RPM of the chipper rotor. If

the RPM drops below the preset range, the feed roller

is stopped. When the RPM are back up to an accept-

able level, the feed roller is reengaged.

the controller also has a “try again” feature. the

controller monitors the hydraulic pressure of the feed

roller. If it senses the level is too high (the feed roller

becomes obstructed) the controller will reverse the feed

roller , removing the material trying to be chipped. the

controller will then engage the roller into the forward

position and try to feed the material again. If this cycle

continues, the obstruction will have to be removed

manually, trimmed, and/or repositioned.

to disable the try again feature, disconnect the 2-pin

connector going to the pressure switch. It is located

above the feed roller motor on the Sa-1987 assembly.

the controller will also flash service alerts when it is

started. Every 15 hours it will flash 5 times to indicate

the chipper blades should be sharpened. Every 100

hours it will flash 10 times to indicate the engine oil

should be changed.

noTe:

The RPM sensor on the rotor must be flashing or

the controller won’t work. Clearance between the sensor

and the bolt must be between 1/32” and 3/32”.

1.

2.

3.

4.

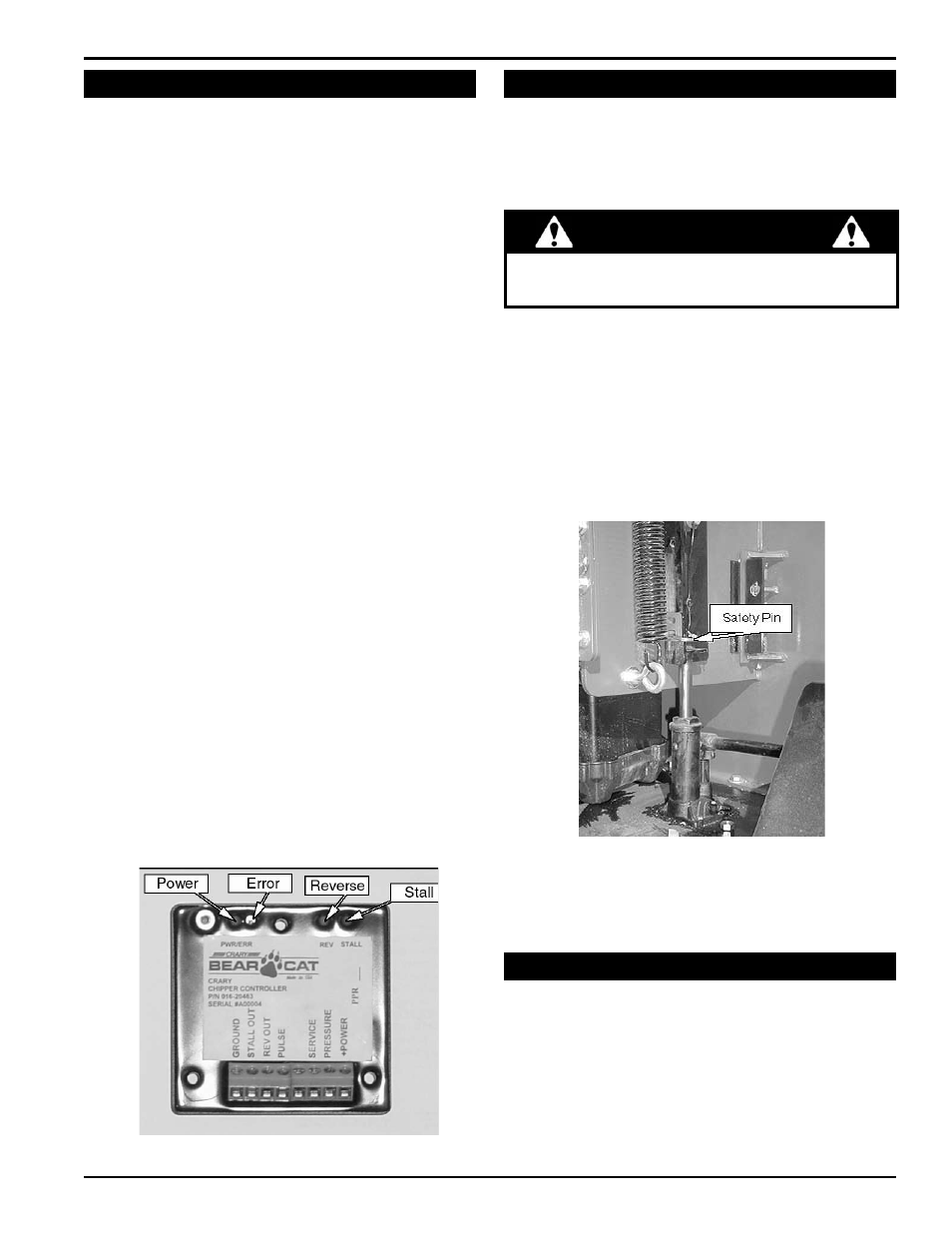

4.7 feed roller boTTle Jack

The feed roller bottle jack is used to raise the feed roller if

chipping material becomes wedged in the feed roller. the

jack will raise the feed roller and remove the tension on

the chipped material.

alloW tHE MaCHINE to CoME to CoMPlEtE

StoP bEFoRE uSINg tHE bottlE JaCk.

Warning

To raise The feed roller:

turn the check valve clockwise to engage the pump

of the jack.

Once the jack is engaged, pump the handle to raise

the feed roller.

Secure the position with the safety pin.

once feed roller is cleared of materials, remove the

safety pin.

turn the check valve counterclockwise to disengage

the pump and lower the feed roller.

1.

2.

3.

4.

5.

The safety pin secures the bottle jack

Move throttle to slowest position.

Move chipper engagement to the engine start posi-

tion.

let machine idle for a few seconds.

turn key to off position.

allow machine to come to a complete stop.

1.

2.

3.

4.

5.

4.8 sToPPing