7 replacing rotor bearings, 8 clearing a plugged rotor, 9 lubrication – Echo CH5540 Owners Manual v.2 User Manual

Page 18: 50 h, Warning

5 INCH PTO CHIPPER

14

SERVICE & MAINTENANCE

WARNING

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE AND MAKE SURE

ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

5.7 REPLACING ROTOR BEARINGS

1. Remove the 3/8" retaining bolt holding access cover to

main frame assembly. Tilt access cover over to allow

rotor access.

2. Remove large belt guard.

3. Remove idler pulley and drive belts. Using the push

bolts from the bushing, remove the bushing, spacer

and pulley from the rotor shaft.

4. Remove the two 1/2" bolts on each rotor bearing and

remove the roll pin from the rotor shaft.

5. Using an overhead hoist or lifting device, lift the rotor

assembly completely out of the frame. The complete

rotor assembly is 140 lbs.

6. Once the rotor assembly is out of the frame, remove

both bearings and place new bearings on shaft.

7. Replace roll pin.

8. Use the overhead hoist or lifting device to return the

complete rotor assembly to the chipper frame.

9. Slide rotor back until the roll pin is tight against the front

bearing. Lock the front bearing and install the 1/2" bolts

on each bearing to secure them to the frame. Tighten

bolts to 75 ft-lbs. . Lock rear bearing.

10. Slide spacer and bushing onto shaft with flange against

bearing and lock bushing to shaft. Attach rotor pulley to

bushing. Replace drive belts and reinstall idler pulley. Check

and adjust chipper anvil if needed. Check alignment of

pulleys and belt tension. Adjust if needed.

11. Replace belt guard and resume operation.

12. Start tractor engine and engage PTO drive clutch (see

tractor owner's manual). Increase engine speed to

rated PTO RPM Position. Test unit; readjust pulleys

if needed.

5.8 CLEARING A PLUGGED ROTOR

1. Shut off power source and allow all moving parts to come

to a complete stop.

2. Remove the retaining bolt holding the access cover to

the main frame assembly and lift up access cover.

3. Clean the debris out of the chipping rotor. Turn the rotor

by hand to be sure it is free to rotate.

4. Close rotor access cover and replace bolt.

5. Start engine and engage drive belt to resume

operation.

5.9 LUBRICATION

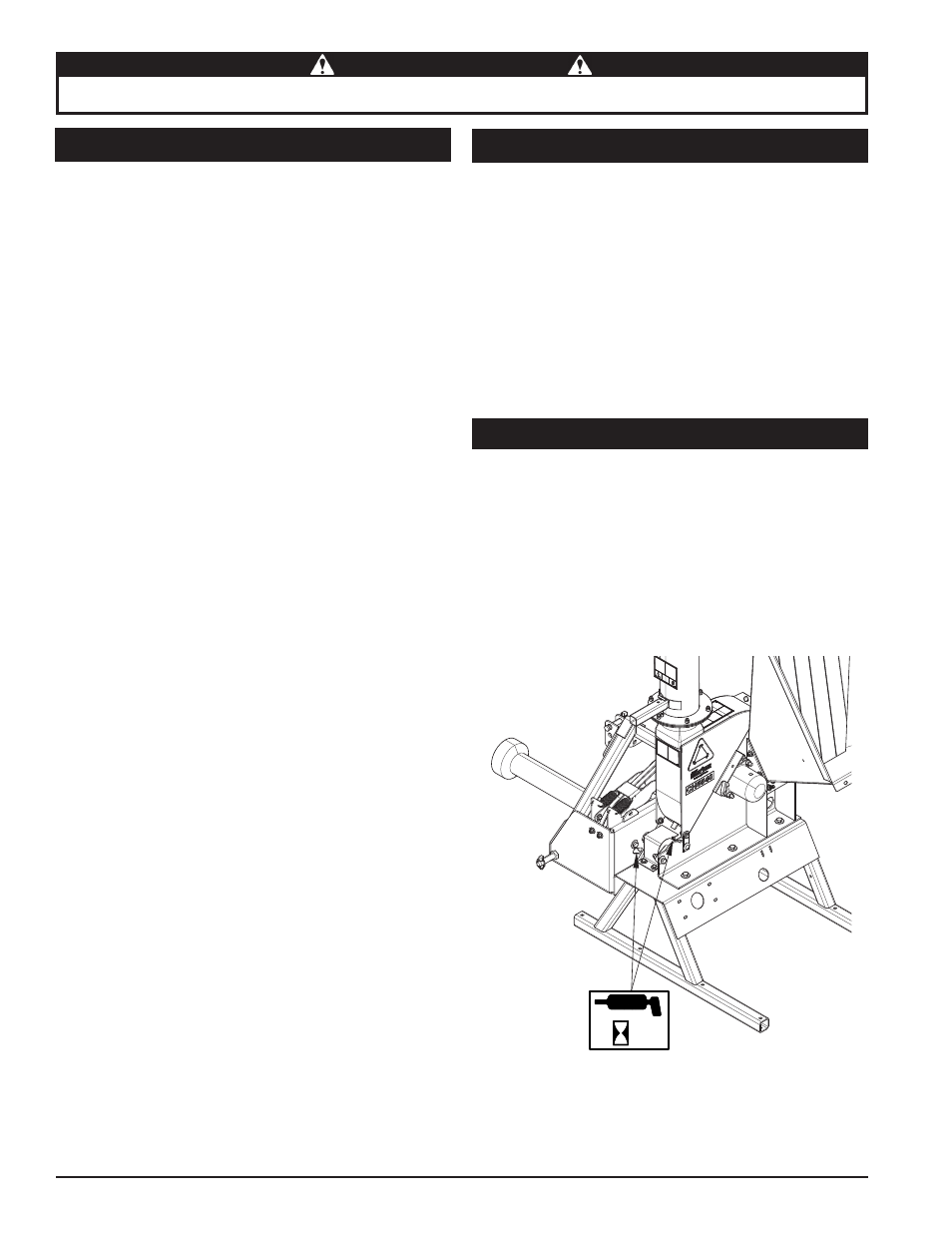

Figure. 5.6. Grease zerks on CH5540

• Two bearings on the rotor shaft.

• One grease zerk on the discharge chute.

• One grease zerk behind pulley.

• One grease zerk underneath bearing.

Lubricate the machine periodically with a lithium-based

grease. Extreme working conditions will require more

frequent greasing.

Grease the following points every 50 hours of operating

time:

50

h