Warning, Englis h – Echo CH6614 Owners Manual v.4 User Manual

Page 11

6 INCH CHIPPER

7

ENGLIS

h

ASSEMBLY

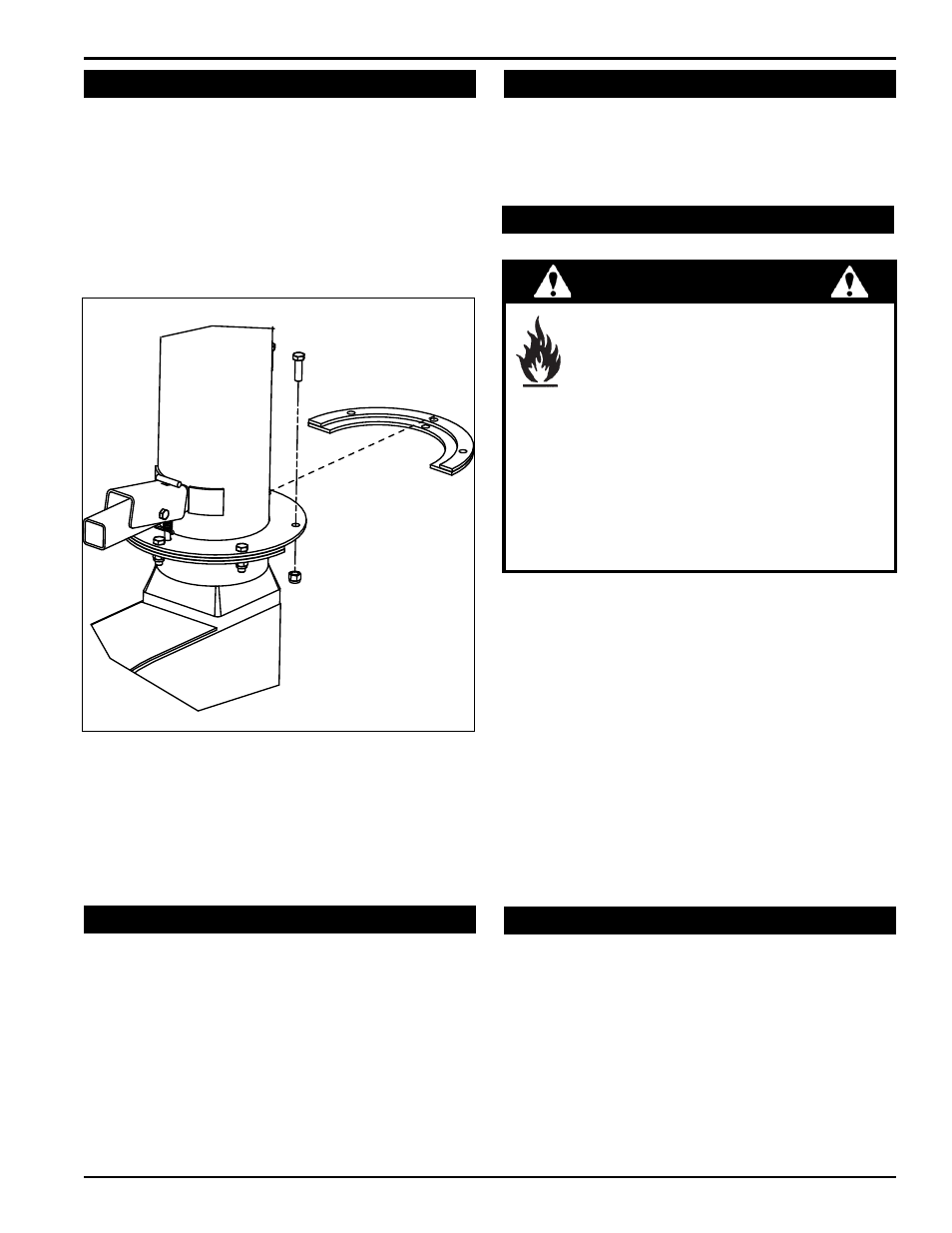

2.4 aTTach dISchaRGE TubE

2.6 add oIL

Check the oil level and, if needed, fill the engine crankcase

with the type and amount of oil specified in the engine

owner’s manual.

use only those types of fuels that are recommended in

your engine owner’s manual.

To add fuel:

Stop engine, wait for all parts to stop moving and

1.

disconnect spark plug wire. Remove key from key

switch. Allow the engine and muffler to cool for at least

three minutes.

Clean area around fuel fill cap and remove cap.

2.

using a clean funnel, fill fuel tank to 1/2” below bottom

3.

of filler neck to provide space for any fuel expansion.

Install fuel fill cap securely and wipe up any spilled

gasoline.

WaRNING

gasoline and diesel fuels are highly

flammable and their vapors are explosive.

To prevent personal injury or property

damage:

Store fuel only in approved containers, in well

ventilated, unoccupied buildings, away from sparks

or flames. A container with a capacity of 2 gallons or

less with a pouring spout is recommended. Do not fill

the fuel tank while the engine is hot or running, since

spilled fuel could ignite if it comes in contact with hot

parts or sparks from ignition. Do not start the engine

near spilled fuel. Never use fuel as a cleaning agent.

DO NOT MIX OIl WITH FuEl.

Check the fluid levels before initial operation and add if

necessary.

The hydraulic pump requires premium hydraulic fluids

containing high quality rust, oxidation, and foam inhibitors.

These include premium turbine oils, API CD engine oils

per SAE J183, M2C33F or g automatic transmission

fluids meeting Allison C-3 or Caterpillar TO-2, and certain

specialty agricultural tractor fluids.

2.5 INSTaLL a baTTERY

you will need to purchase a battery. Choose a battery that

meets or exceeds the following specifications:

Nominal Voltage:12 Volts

Size: 7-1/8" x 3" x 6-9/16"

Rated Capacity:18 Ah

Type: MKES17-12

2.7 add GaSoLINE

2.8 add hYdRauLIc FLuId

Slide the tube onto the mounting flange on the chipper

1.

frame (Figure 2.4). The discharge clamp should slide

underneath the lip of the flange. Tighten the bolts to

secure it.

Install the second half of the spacer and clamp on the

2.

discharge tube with 3/8" x 1-1/4" bolts and nuts.

Rotate the tube 360 degrees and lock it in place with

3.

the lock pin to make sure it is mounted correctly.

Fig. 2.4