8 replacing hydraulic drive belt, 9 fill coolant (diesel), 10 adjusting the chipper anvil – Echo 76624 Owners Manual v.4 User Manual

Page 23: English, Adjustment nuts

19

6 INCH CHIPPER

ENGLISH

SERVICE & MAINTENANCE

BEFORE INSPECTINg OR SERVICINg ANy PART OF THIS MACHINE, SHuT OFF POWER SOuRCE,

DISENgAgE THE HyDRAulICS, AND MAKE SuRE All MOVINg PARTS HAVE COME TO A COMPlETE STOP.

WaRNING

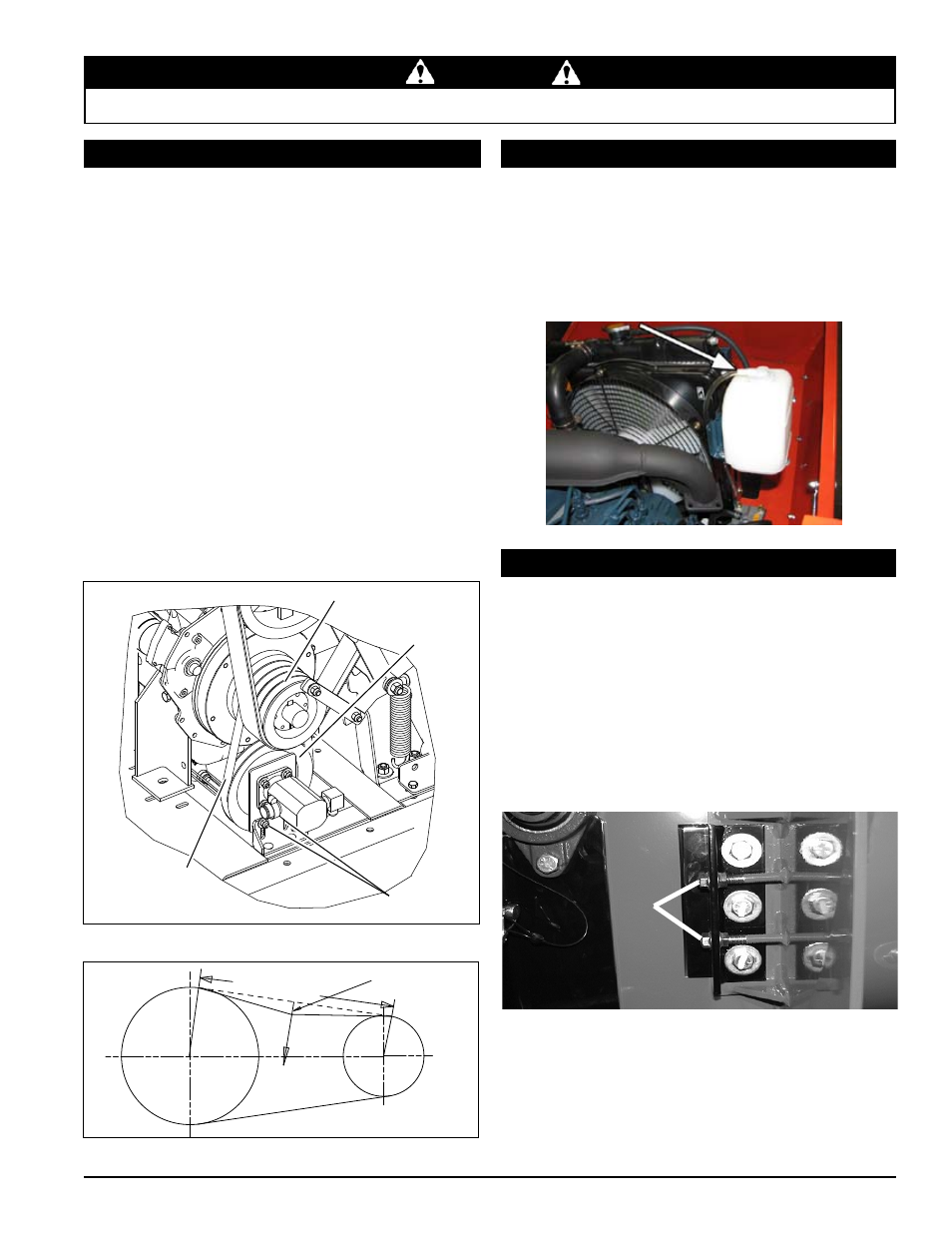

5.8 REpLaCING HYDRauLIC DRIvE bELT

Remove drive belt according to instructions in Section

1.

5.5.

loosen the two bolts under the pump. Access is from

2.

underneath chipper (see figure below).

Slide the pump up, remove the loosened hydraulic

3.

belt and discard.

Install the new hydraulic belt.

4.

Replace the drive belt according to directions in Section

5.

5.5.

Tighten the nuts on the adjusting bolt to move the pump

6.

mounting bracket. Stop when the belt deflection at the

center of the belt is 7/16" when a 20 lb. load is placed

against the belt (see figure below).

tighten the mounting bolts on the pump mounting

7.

bracket to the proper torque.

5.9 FILL CooLaNT (DIESEL)

LOOSEN THESE

TWO BOLTS

HYDRAULIC

DRIVE BELT

IDLER PULLEY

HYDRAULIC

BELT PULLEY

Coolant tank for diesel engine

Replace hydraulic drive belt as needed

5.10 aDJuSTING THE CHIppER aNvIL

lift rotor access cover and expose rotor.

1.

Measure the amount of clearance between chipping

2.

blade and chipper anvil from inside of housing.

Loosen the three 1/2 inch bolts that hold the chipper

3.

anvil to the frame (see below).

Adjust inward or outward to the desired measurement,

4.

using the adjustment nuts provided.

Tighten bolts on chipping block to 75 ft-lbs. and resume

5.

operation.

If chipper anvil edge is damaged or worn unevenly, remove

the three bolts holding the anvil and use one of the other

three edges. Replace as necessary.

Adjustment

Nuts

The chipping blades should clear the anvil by 1/16 inch to

1/8 inch. Check the clearance every 8 hours of operation

and adjust if needed. The chipping anvil is reversible. All

four sides of the anvil can be used for chipping.

To adjust the anvil:

The condition of the hydraulic drive belt should be checked

annually, or after every 25 hours of operation. Replace

the belt if it is cracked, worn, frayed, or stretched.

to replace the belt:

Proper belt tension is a deflection of 7/16" for a 20 lb. load

SPAN LENGTH

FORCE

20 LBS

7/16" DEFLECTION

The diesel engine is tested before shipping. In order to test

the equipment the fluid levels are filled. However, before

starting the machine, and every time the engine is started

thereafter, be sure to check the coolant level. If the level

is low, add fluid.

Refer to the engine owner’s manual for coolant information

and maintenance.