Hydraulic system troubleshooting -19 – JLG 260MRT Service Manual User Manual

Page 85

SECTION 3 - GENERAL ELECTRICAL INFORMATION & SCHEMATICS

3121801

– JLG Lift –

3-19

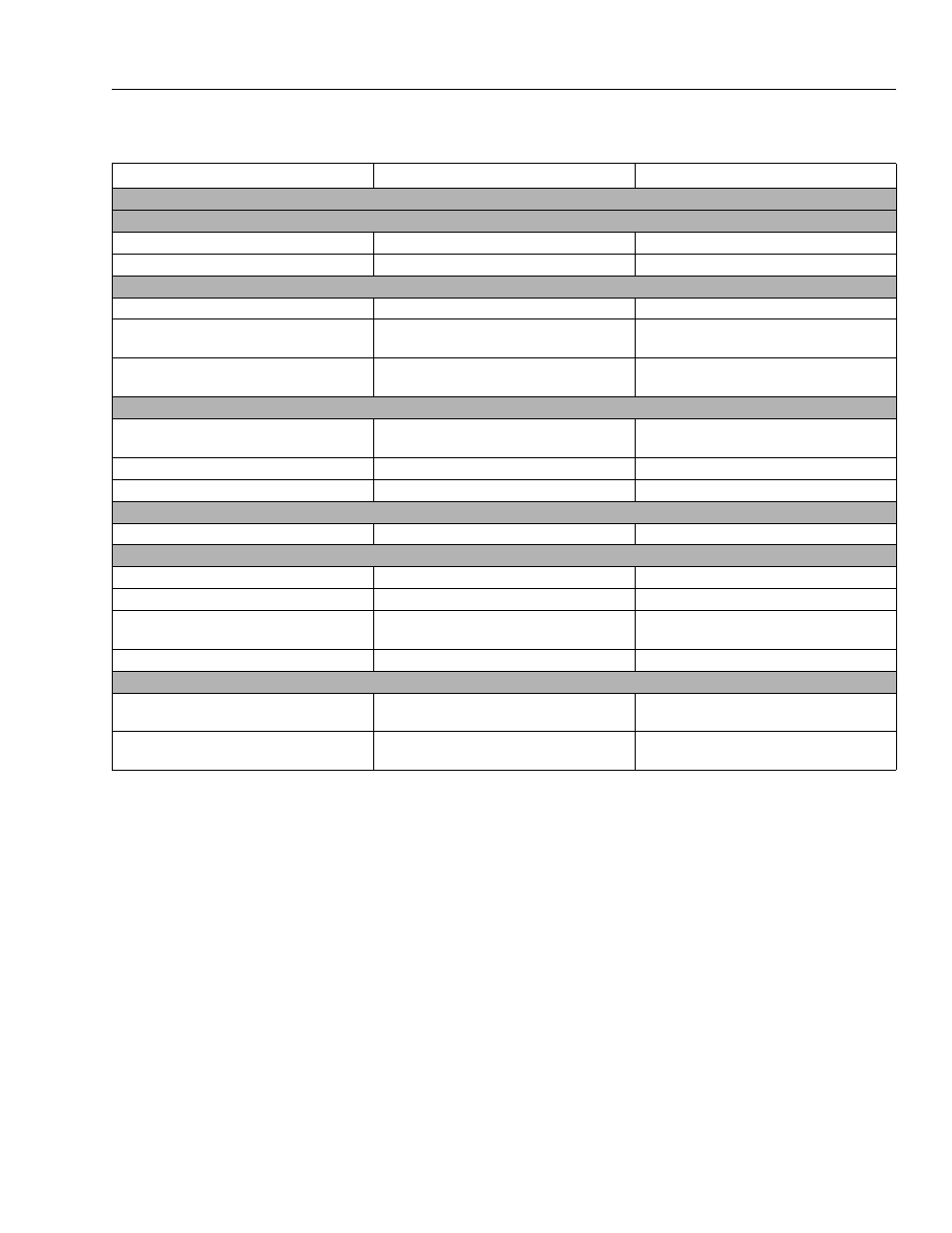

Table 3-3. Hydraulic System Troubleshooting

TROUBLE

PROBABLE CAUSE

REMEDY

Hydraulic System - General

Hydraulic Pump Noisy

Air bubbles in oil. (Reservoir too low.)

Replenish oil as necessary.

Oil filter dirty.

Clean and/or replace filter as necessary.

Pump cavitating. (Vacuum in pump due to oil starvation)

Oil in reservoir low.

Replenish oil as necessary.

Restricted reservoir air vent.

Clean vent.

Oil viscosity too high.

Drain system and replace with recom-

mended oil. Refer to Hydraulic Oil.

System overheating

Oil viscosity too high.

Drain system and replace with recom-

mended oil. Refer to Hydraulic Oil.

Main relief valve set too high.

Adjust relief valve to proper pressure.

Hydraulic system oil low.

Replenish oil as necessary.

Pump not delivering oil

Defective pump.

Repair or replace pump.

System pressure too low

Main relief valve set too low.

Reset valve as required

Hydraulic pump not functioning properly. Repair or replace pump.

Leak in component, line or fitting.

Repair or replace component, line or fit-

ting.

Scored valve spool; scored cylinder.

Replace valve; replace cylinder.

System(s) operate erratically

Sticking or binding valve cartridge, piston

rod, etc.

Clean, repair or replace components as

necessary

Hydraulic oil not at operating tempera-

ture.

Allow oil sufficient time to warm up.