Lubrication diagram -5, Lubrication chart -5 – JLG 260MRT Service Manual User Manual

Page 13

SECTION 1 - SPECIFICATIONS

3121801

– JLG Lift –

1-5

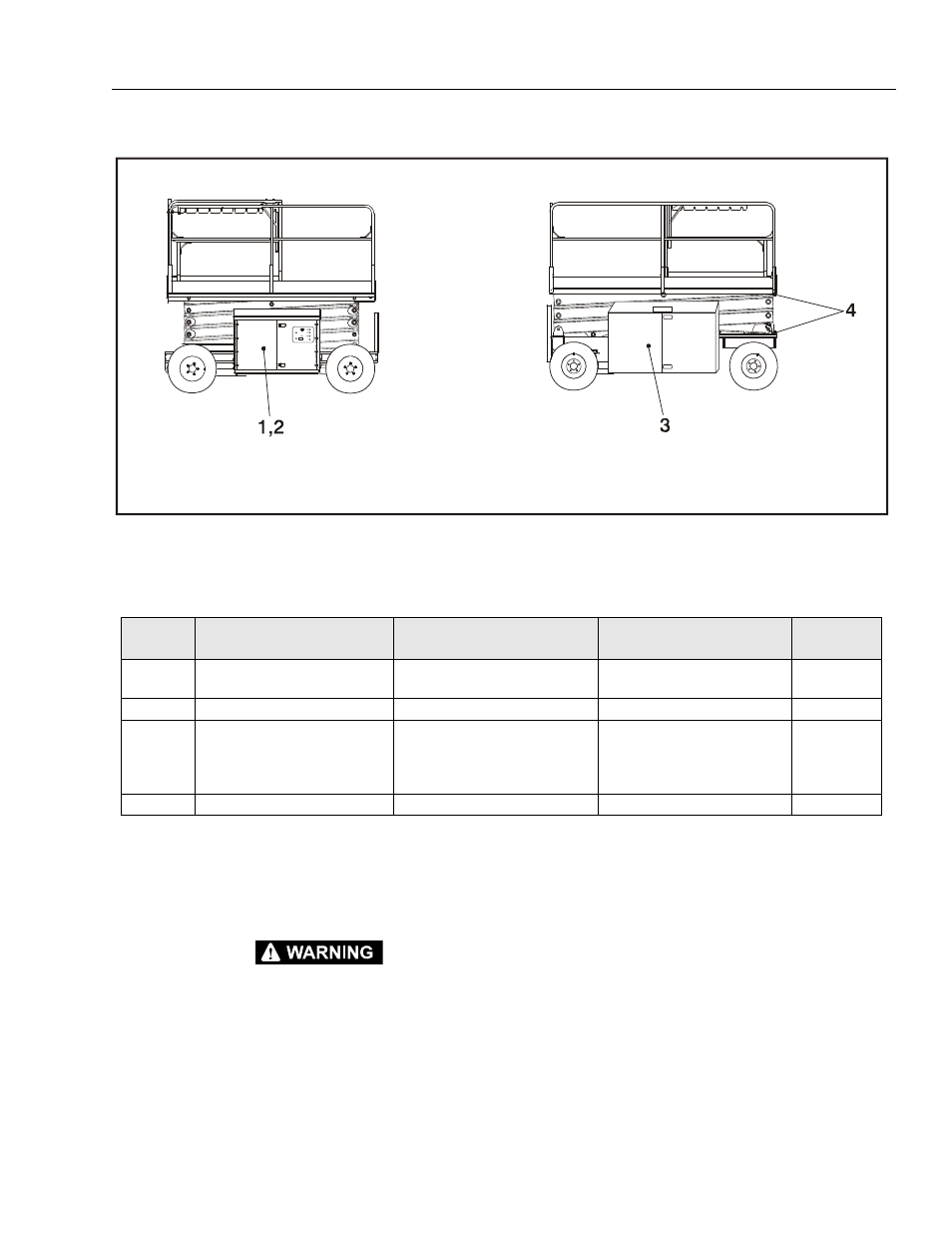

Figure 1-2. Lubrication Diagram

Table 1-14. Lubrication Chart

INDEX NO

COMPONENT

NUMBER/TYPE LUBE POINTS

LUBE METHOD

INTERVAL

HOURS

1

Hydraulic Oil Reservoir

Fill Cap/Drain Plug

HO - Check HO Level

HO - Change HO

10/500

2

Hydraulic Filter Element

N/A

Initial Change - 50 Hours

250

3

Engine Crankcase,

Engine Oil Filter,

Engine Fuel Filter,

Engine Fuel Filter (Kubota DF752)

Fill Cap/Drain Plug,

Filter Element,

Filter Element,

Filter Element

Check Engine Oil Level,

Initial Change - 50 Hours,

Check & Clean every 100 hrs,

Check & Clean every 100 hrs

10/100,

200,

400,

Yearly

4

Rail Slides

N/A

MPG - Brush

100

KEY TO LUBRICANTS:

MPG - Multi-purpose Grease

EPGL - Extreme Pressure Gear Lube

HO - Hydraulic Oil (Mobil 424)

TO AVOID PERSONAL INJURY, USE SAFETY PROP FOR ALL

MAINTENANCE REQUIRING PLATFORM TO BE ELEVATED.

NOTE: Be sure to lubricate like items on each side

Recommended lubricating intervals are based on

machine operations under normal conditions. For

machines used in multi-shift operations and/or

exposed to hostile environments or conditions,

lubrication frequencies must be increased accord-

ingly.

NOTE: Operate hydraulic functions through one complete

cycle before checking hydraulic oil level in tank. Oil

should be visible in ADD sight window on hydraulic

tank. If oil is not visible, add oil until oil is visible in

both ADD and FULL sight windows on tank. Do not

overfill tank.

Any time the pump coupling is removed, coat

splines of coupling with Texaco Code 1912 grease

prior to assembly.