JLG 20VP (3120727) Operator Manual User Manual

Page 17

SECTION 2 - PREPARATION AND INSPECTION

3120727

– JLG Lift –

2-3

Operation and Safety and ANSI

Responsibilities Manual

Ensure a copy of manual is enclosed in the manual stor-

age box.

Lubrication

For those parts pointed out in the Walk-Around Inspection

requiring lubrication, refer to the Lubrication Chart, Table

2-1., for specific time interval requirements.

Hydraulic oils must have anti-wear qualities at least to API

Service Classification GL-3, and sufficient chemical stabil-

ity for mobile hydraulic system service. JLG Industries,

recommends Mobilfluid 424 hydraulic oil, which has an

SAE viscosity of 10W-30 and a viscosity index of 152.

For cold weather applications, i.e. when temperatures

remain consistently below +20°F (–7°C) JLG recom-

mends using Mobil DTE 13 hydraulic oil.

2.5

DAILY FUNCTIONAL CHECK

TO AVOID INJURY DO NOT OPERATE A MACHINE UNTIL ALL

MALFUNCTIONS HAVE BEEN CORRECTED. USE OF A MALFUNC-

TIONING MACHINE IS A SAFETY VIOLATION.

Once the Walk-Around Inspection is complete, a Func-

tional Check of all systems should be performed in an

area free of overhead and ground level obstructions. Per-

form a Functional Check in accordance with the following

procedures:

Set-up machine for operation, according to instructions in

Section 4-3, “Machine Operation”.

NOTE: 20VP MODELS WITH UNDERWRITERS LABORA-

TORY (EE) RATING OPTION ONLY, include a mas-

ter ON/OFF switch located on top of the rear cover of

the machine. This control must be set to the ON

position before the following function checks can be

completed.

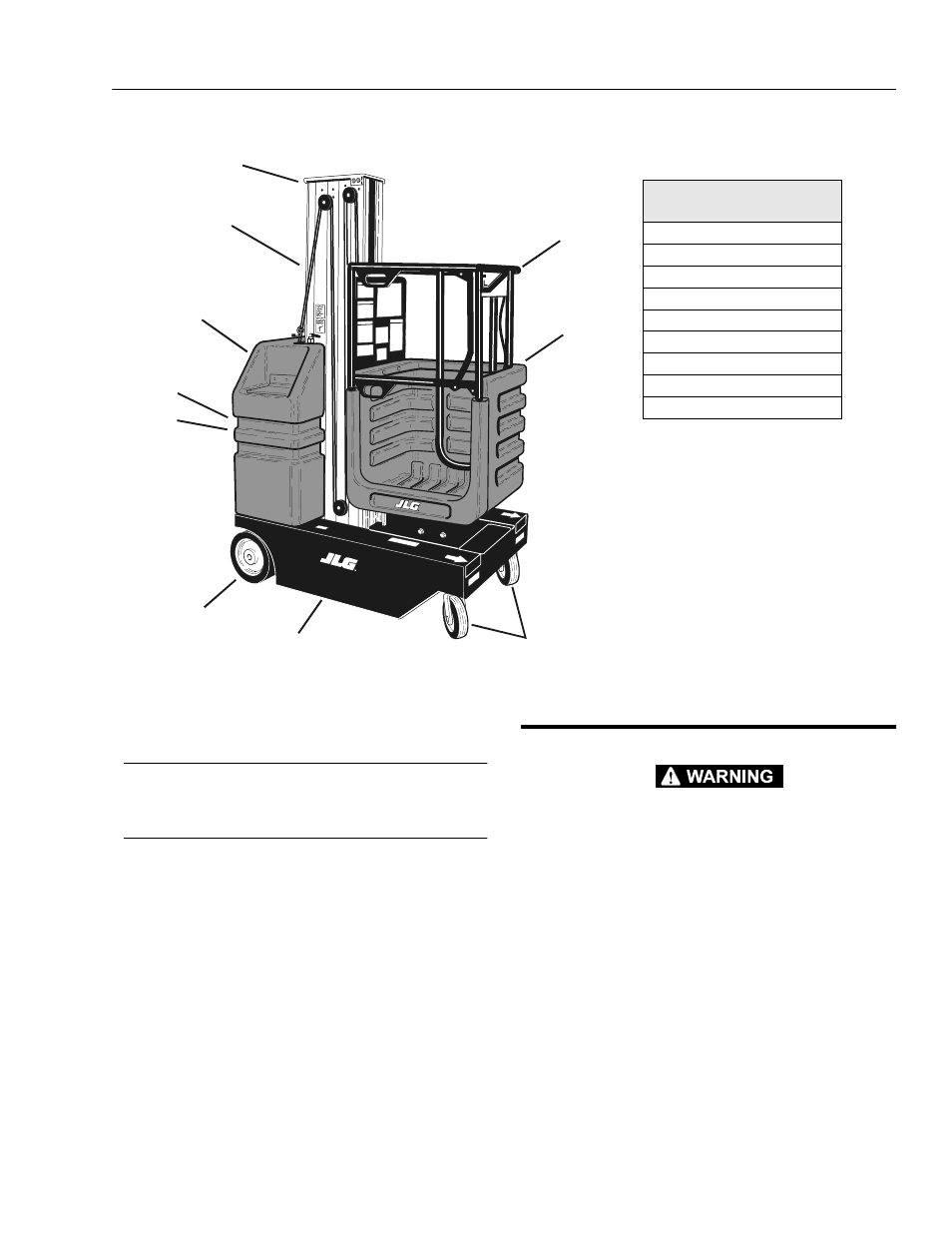

Figure 2-1. Daily Walk-Around Inspection.

1

1

2

3

4

5

6

7

8

9

Daily Walk-Around

Inspection Items

1. Drive and Castor Wheels

2. Base Frame

3. Battery/Battery Charger

4. Motor/Pump/Reservoir Unit

5. Ground Controls

6. Mast Assembly

7. Manual Brake ReleaseControl

8. Platform Assembly

9. Platform Controls