Pre-start inspection, Pre-start inspection -4 – JLG 1100SB Operator Manual User Manual

Page 24

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2-4

– JLG Lift –

3121264

Pre-Start Inspection

The Pre-Start Inspection should include each of the follow-

ing:

1. Cleanliness – Check all surfaces for leakage (oil, fuel,

or battery fluid) or foreign objects. Report any leakage to

the proper maintenance personnel.

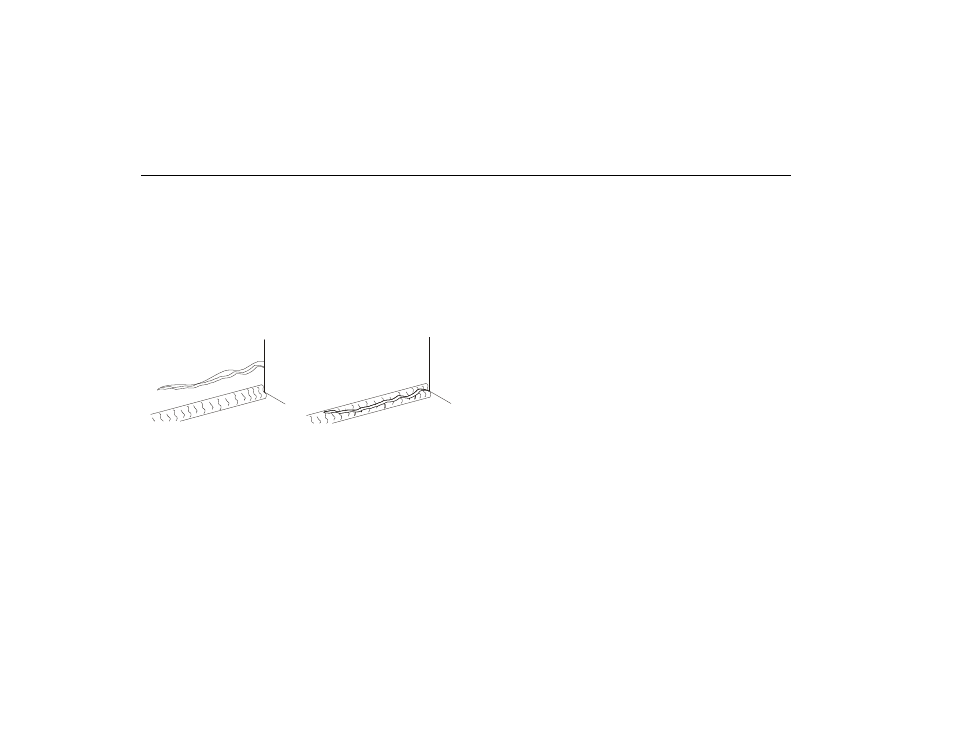

2. Structure - Inspect the machine structure for dents,

damage, weld or parent metal cracks or other discrep-

ancies.

3. Decals and Placards – Check all for cleanliness and

legibility. Make sure none of the decals and placards are

missing. Make sure all illegible decals and placards are

cleaned or replaced.

4. Operators and Safety Manuals – Make sure a copy of

the Operator and Safety Manual, AEM Safety Manual

(ANSI markets only), and ANSI Manual of Responsibili-

ties (ANSI markets only) is enclosed in the weather

resistant storage container.

5. “Walk-Around” Inspection – Refer to Figure 2-2. and

6. Battery – Charge as required.

7. Fuel (Combustion Engine Powered Machines) – Add the

proper fuel as necessary.

8. Engine Oil Supply - Ensure the engine oil level is at the

Full mark on the dipstick and the filler cap is secure.

9. Hydraulic Oil – Check the hydraulic oil level. Ensure

hydraulic oil is added as required.

10. Accessories/Attachments - Reference the Operator

and Safety Manual of each attachment or accessory

installed upon the machine for specific inspection, oper-

ation, and maintenance instructions.

11. Function Check – Once the “Walk-Around” Inspection

is complete, perform a functional check of all systems in

an area free of overhead and ground level obstructions.

Refer to Section 4 for more specific operating instruc-

tions.

12. Boom Control System Check - Perform a check of the

boom control system as specified in this section.

Parent Metal Crack

Weld Crack