6 supplemental information, Supplemental information -20, Wheel torque chart -20 – JLG M400 Operator Manual User Manual

Page 102

SECTION 6 - GENERAL SPECIFICATIONS & OPERATOR MAINTENANCE

6-20

– JLG Lift –

3121644

2.

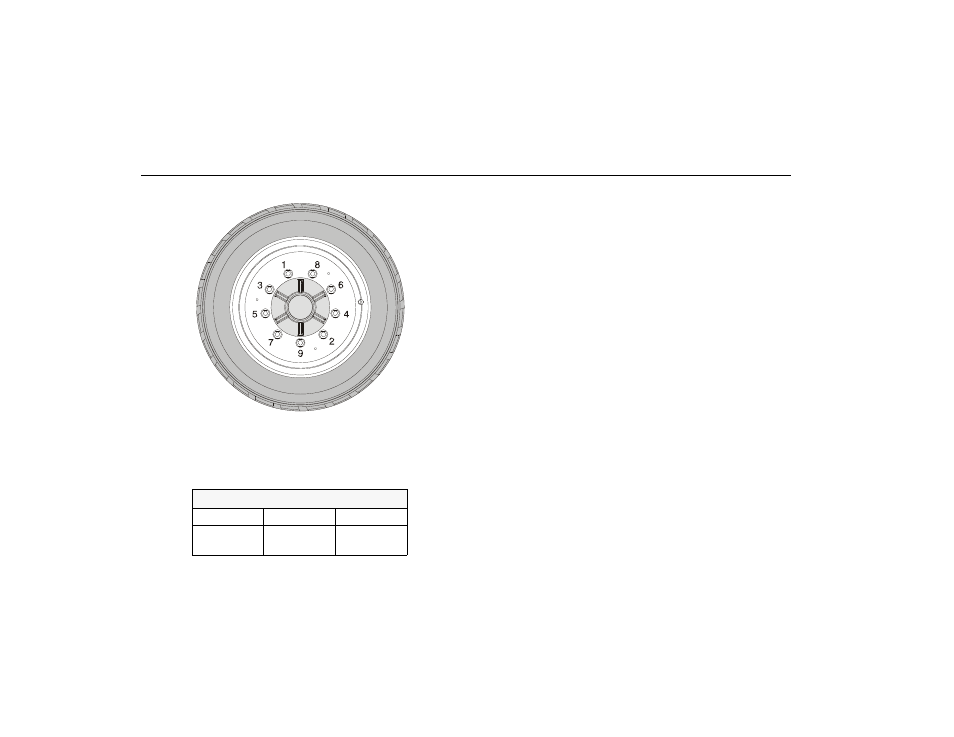

Tighten nuts in the following sequence:

3.

The tightening of the nuts should be done in stages. Follow-

ing the recommended sequence, tighten nuts per wheel

torque chart.

4.

Wheel nuts should be torqued after first 50 hours of opera-

tion and after each wheel removal. Check torque every 3

months or 150 hours of operation.

6.6

SUPPLEMENTAL INFORMATION

The following information is provided in accordance with the

requirements of the European Machinery Directive 2006/42/EC

and is only applicable to CE machines.

For electric powered machines, the equivalent continuous A-

Weighted sound pressure level at the work platform is less than

70dB(A)

For combustion engine powered machines, guaranteed Sound

Power Level (LWA) per European Directive 2000/14/EC (Noise

Emission in the Environment by Equipment for Use Outdoors)

based on test methods in accordance with Annex III, Part B,

Method 1 and 0 of the directive, is 104 dB.

The vibration total value to which the hand-arm system is sub-

jected does not exceed 2,5 m/s

2

. The highest root mean square

value of weighted acceleration to which the whole body is sub-

jected does not exceed 0,5 m/s

2

.

Table 6-11. Wheel Torque Chart

TORQUE SEQUENCE

1st Stage

2nd Stage

3rd Stage

40 ft. lbs.

(55 Nm)

100 ft. lbs.

(130 Nm)

170 ft. lbs.

(255 Nm)