Burnham CHG User Manual

Page 3

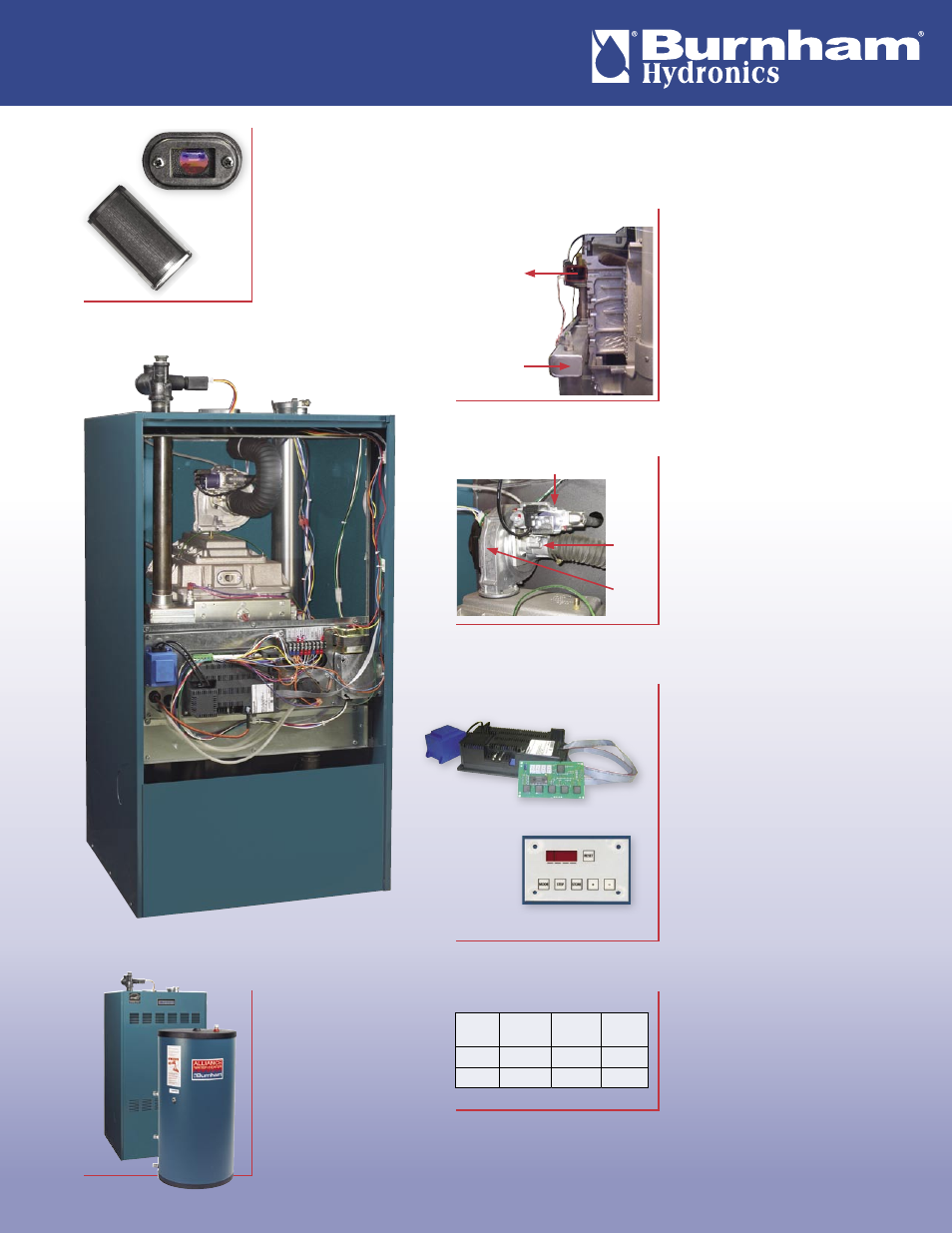

The flame can be continuously

modulated from an orange

glow to a full blue flame.

The burner is located on the

top of the heat engine forcing

the heat down while the water

flows upward. This allows the

condensation to drain down

and away from the boiler.

CHG Site Glass & Burner

Abundant domestic hot water

is available with a matching

Alliance indirect-fired hot

water heater. Select from

several sizes to meet your

specific needs. In addition, the

CHG boiler control module

is preset for domestic hot

water priority and set point

temperature.

Domestic Hot Water

CHG boilers utilize a pre-mix combustion assem-

bly that includes a modulating gas valve, vari-

able speed blower and a venturi to provide an

optimal fuel/air mixture to a stainless steel mesh

burner. Together these components accurately

and efficiently help control the fully modulating

combustion process which automatically adjusts

the boiler’s firing rate to match your heating

needs.

Premix Technology

Negative regulated gas valve

with factory set outlet pressure.

Venturi

Variable

Speed

Blower

The CHG incorporates a sealed combustion

system that uses outside air for combustion and

the safe and proven AL29-4C stainless steel ma-

terial for venting the exhaust. Both horizontal

(“sidewall”) and vertical (“through-the-roof”)

venting options are available.

CHG Venting

Boiler

Model

Horizontal

Vent Max.

Vertical

Vent Max.

Vent

Diameter

CHG150

55 ft.

49.5 ft.

3 in.

CHG225

55 ft.

47 ft.

4 in.

The MCBA microprocessor control manages all

boiler functions including supervising the com-

bustion process and monitoring key operating

functions. Included is a digital display that can

provide detailed boiler information as well as be

an invaluable service and troubleshooting tool.

The MCBA module stores set points for boiler

and domestic hot water supply temperatures,

and monitors supply and return water tempera-

tures, flue gas temperature, the flame sensor,

and the included outdoor reset. The boiler con-

trol module allows for continuous modulation

(firing rates) by varying the combustion fan

speed.

Boiler Control Module & Outdoor Reset

Supply

Manifold

Return

Manifold

The CHG castings incorporate a multi-pass water

flow with the return water entering the lower

manifold and progressing upward to the sup-

ply manifold. This counterflow from bottom to

top provides for maximum heat transfer while

the serpentine pattern offers low pressure drop.

Each section’s water flow is independent with no

port connections between sections. The supply

and return manifolds are designed to balance

the flow across all sections.

Boiler Operations

Cutaway view showing

actual water flow path.