Raising and lowering the platform, Travel with work platform elevated, Emergency lowering – Snorkel SL30RT-sn13300+ User Manual

Page 4: Switching fuels (gas / propane only), After use each day, Parking brake release (figure 3)

4

Raising and Lowering The Platform

1. Position the Drive/Lift Switch to LIFT.

2. While holding the Control Lever so the Inter-

lock Lever is depressed, push the Control

Lever slowly to UP to raise the platform. Push-

ing the Control Lever farther increases the lift

speed.

3. When the work task is completed, position the

Drive/Lift Switch to LIFT and lower the platform

by pulling back on the Control Lever until the

platform is fully lowered.

Travel With Work Platform Elevated

Travel with platform elevated ONLY on firm and

level surfaces.

NOTE: The Work Platform will travel at reduced

speed when in the elevated position.

1. Check that the route is clear of persons,

obstructions, holes and drop-offs, is level and

capable of supporting the wheel loads.

2. Check clearances above, below and to the

sides of platform.

3. Position the Drive/Lift Switch to the DRIVE

position.

4. Push the Control Lever to FORWARD or

REVERSE for the desired direction of travel.

If the machine quits driving and the Tilt Alarm

sounds, immediately lower the platform and

move the machine to a level location before re-

elevating the platform.

Emergency Lowering

The Emergency Lowering Valve is located on

the left hand side of the chassis through the

cutout in the Control Module cover.

1. Open the Emergency Lowering Valve by

pushing in and turning the knob counterclock-

wise approximately ¼ turn, the knob will pop

out, disengaging detent.

2. Once the platform is fully lowered, be certain

that the Emergency Lowering Valve is closed

again. The platform will not elevate if the

Emergency Lowering Valve has not been

closed.

3. To close the Emergency Lowering Valve, push

the knob in and turn approximately ¼ turn

clockwise until the detent engages.

Switching Fuels (Gas / Propane Only)

1. With engine running push the Fuel Selector

Switch (Figure 1) to the center position.

2. After the engine has quit running select the

appropriate fuel supply.

3. Restart the engine.

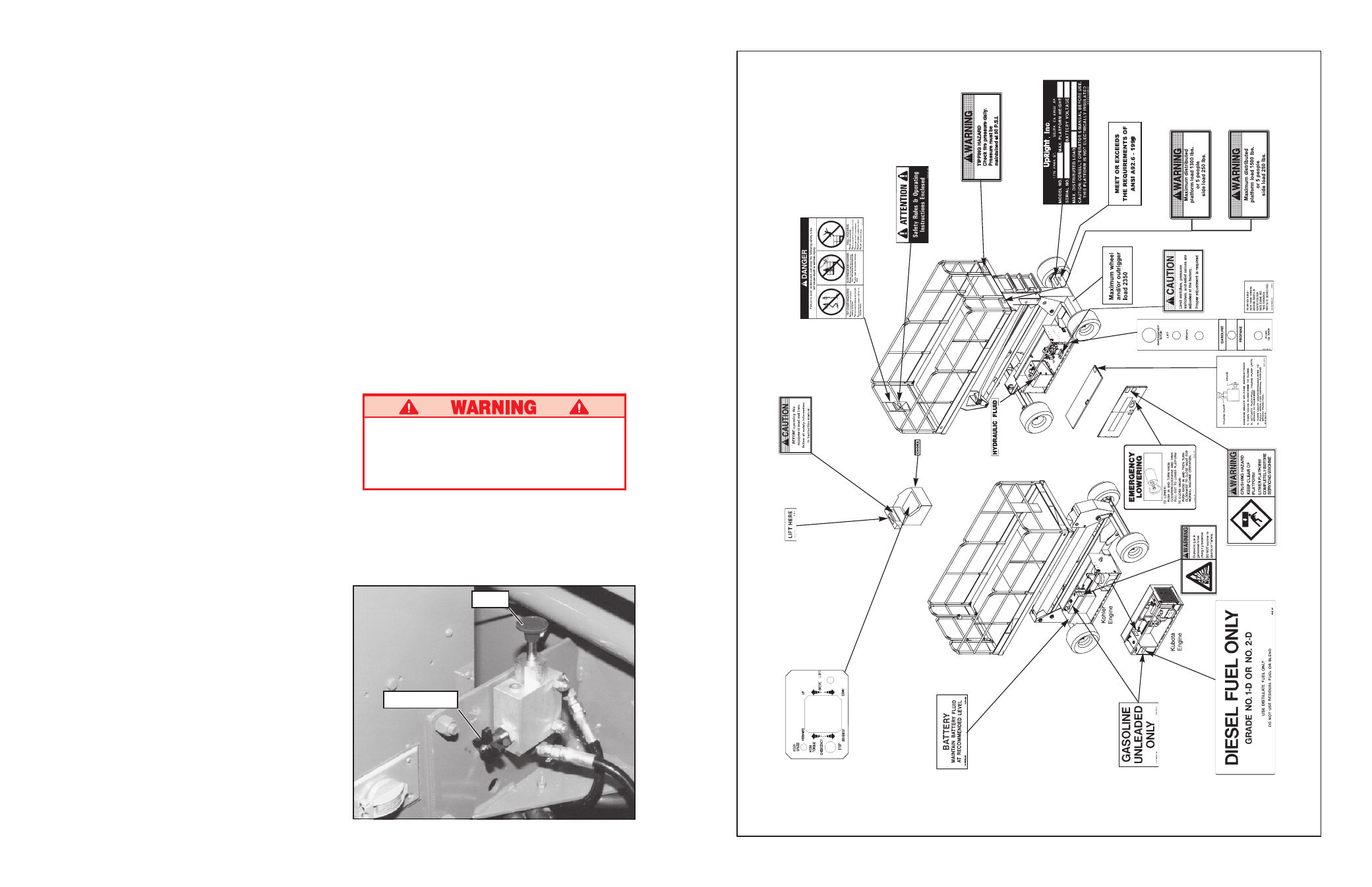

Figure 3: Brake Release Pump

After Use Each Day

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably

under cover, secure against vandals, children

or unauthorized operation.

3. Turn the Key Switch to OFF and remove the

key to prevent unauthorized operation.

Parking Brake Release (Figure 3)

Perform the following only when the machine will

not operate under its own power and it is neces-

sary to move the machine or when towing the

machine up a grade or winching onto a trailer to

transport.

1. Close the needle valve by turning the knob

clockwise.

2. Pump the Brake Release Pump until the Parking

Brakes release and the wheels can be turned.

3. The machine will now roll when pushed or

pulled.

4. Be sure to open the needle valve and verify

that the Parking Brakes have engaged before

the machine is operated.

Never operate work platform with the

Parking Brakes inoperative. Serious injury

or damage could result.

Never tow faster than 1 ft./sec. (.3 m/sec).

Pump

Needle Valve

9

Note:

Labels

can

be

ordered

by

using

Part

Number

located

by

each

label.

For

m

achines

equipped

with

options

consult

Service

Manual.

SL-26/30 RT LABEL INSTALLATION: THESE LABELS SHALL BE PRESENT AND IN GOOD

CONDITION BEFORE OPERATING THE WORK PLATFORM. BE SURE TO READ, UNDER-

STAND AND FOLLOW THESE LABELS WHEN OPERATING THE WORK PLATFORM.

061205-000 1-REQUIRED

061220-002 1-REQUIRED

SL30RT 101250-008 1-REQUIRED

SL26RT 101250-008 1-REQUIRED

065791-000 1-REQUIRED

061515-000 1-REQUIRED

066562-000 1-REQUIRED

064421-000 1-REQUIRED

064414-000 1-REQUIRED

063423-000 1-REQUIRED

066555-000 2-REQUIRED

062524-001 1-REQUIRED

066568-000 1-REQUIRED

066552-000 1-REQUIRED

060197-000 1-REQUIRED

027898-000 1-REQUIRED

(DIESEL

ONLY)

064166-000 1-REQUIRED (GASOLINE

ONLY)

010076-001 1-REQUIRED

066550-004 1-REQUIRED

066554-000 1-REQUIRED

066563-000 1-REQUIRED

030624-024 1-REQUIRED

101252-012 2-REQUIRED