Maintenance, Storage, Routine service – Snorkel MX19-sn1600-8791 User Manual

Page 5

5

Maintenance

Never perform service on the work platform

in the Elevating Assembly area while the

platform is elevated without first blocking

the Elevating Assembly.

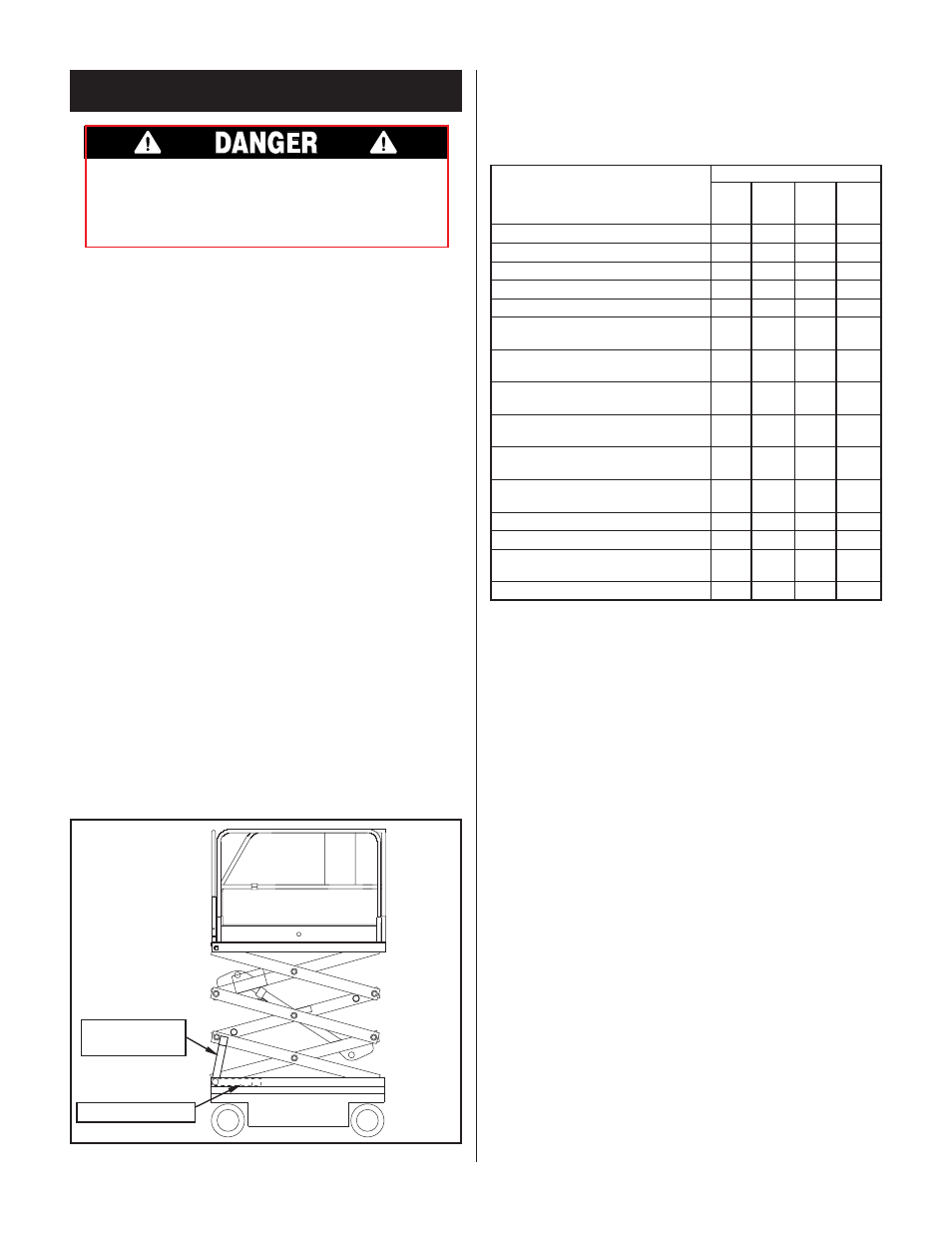

Blocking Elevating Assembly (Figure 6)

Installation

1. Park the work platform on firm level ground.

2. Verify Platform Emergency Stop Switch is ON.

3. Turn Chassis Key Switch to CHASSIS.

4. Position Chassis Lift Switch to UP and elevate

platform approximately 7 Ft. (2.1 m).

5. Rotate Scissor Brace to a verticle position.

6. Lower Platform until end of Scissor Arm Weld-

ment rests on Brace.

Storage

1. Slowly raise Platform from the Chassis Controls,

while holding Brace, until the end of the Scissor

Arm Weldment clears the Scissor Brace.

2. Rotate Scissor Brace forward to rest on Chassis.

Figure 6: Blocking Elevating Assembly

Routine Service

Use the following table as a guide for routine

maintenance, refer to the Service Manual for

complete service instructions.

SERVICE OPERATION

INTERVAL

Monthly 6 Months 2 Years

Daily

or

or

or

50 Hrs. 250 Hrs. 1000 Hrs.

Clean entire work platform

X

Check battery fluid level

X

Charge batteries

X

Check tires for damage

X

Check hydraulic fluid level

X

Check for peeling, faded or

X

missing labels & replace

Check deck and guardrail

X

fasteners for proper torque

Inspect elevating assembly

X

for bends or cracks

Check for & repair collision

X

damage

Check emergency lowering

X

valve operation

Check electric motor

X

brushes

Check pivot pin retaining rings

X

Change hydraulic filter

X

Check all fasteners for

X

proper torque

Change hydraulic fluid

X

Scissor Brace

Installed

Stowed Position