Connecting the equipment – Lukas HP Cylinders User Manual

Page 11

11

For dust protection, the supplied dust protection caps must be refitted.

WARNING / CAUTION / ATTENTION!

Some quick-disconnect couplings have special functions and may therefore

not

be

unscrewed from the hydraulic lines and/or swapped!

NOTE:

It is only possible to connect devices when the hoses are

depressurised.

CAUTION!

Always connect the return hose first and then the supply hose!

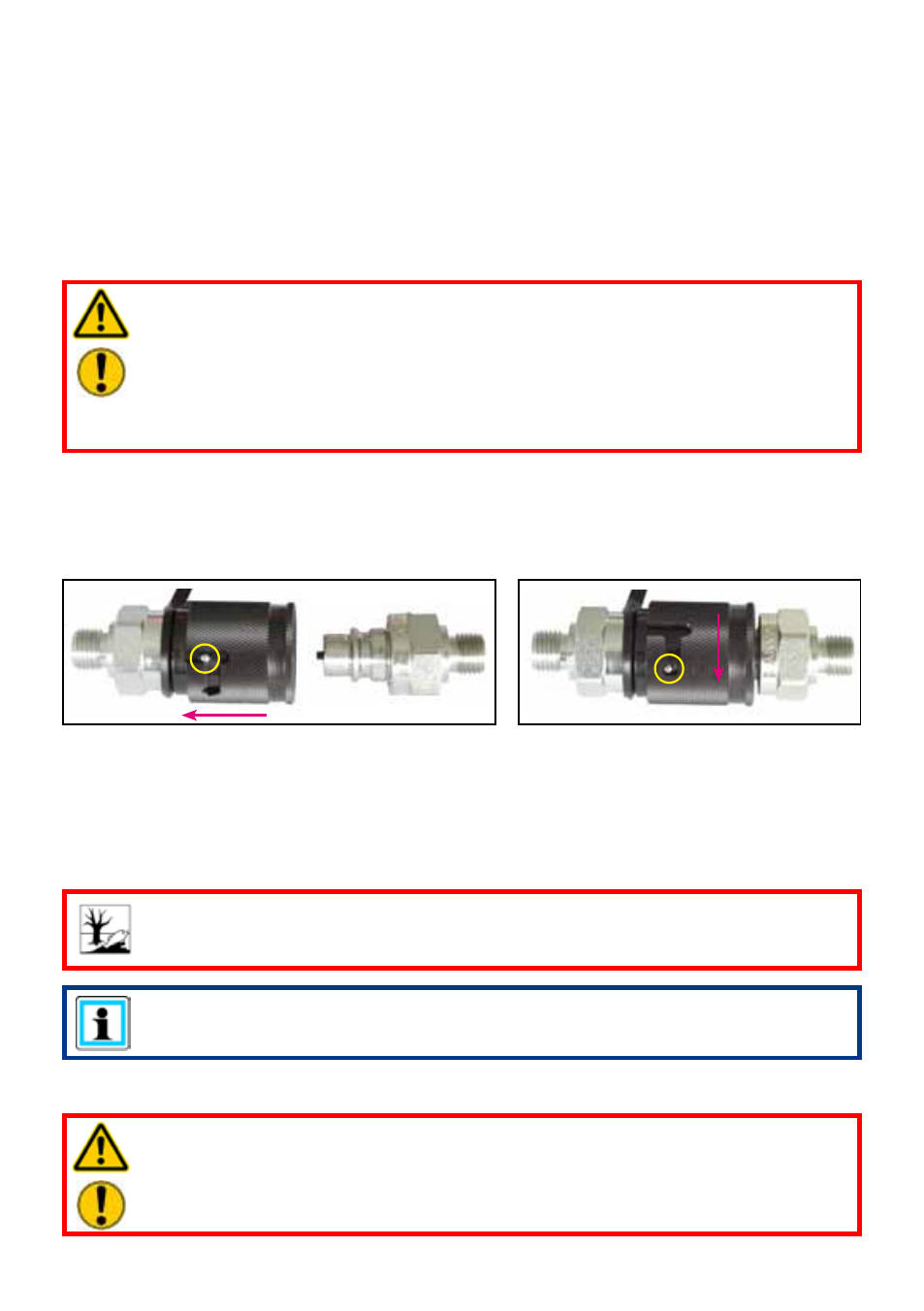

Before coupling, remove the dust protection caps and then pull back and hold the locking

sleeve of the female coupling half (position X). Connect the male and female coupling together

and release the locking sleeve. Then turn the locking sleeve to position Y. The connection has

now been made and locked. Disconnection is carried out in the reverse order. Hoses can be

connected only when

depressurised. For dust protection, the supplied dust protection caps

must be refitted.

6.2 Coupling quick-disconnect couplings

The equipment is connected to the hydraulic pump via quick-disconnect-coupling halves

(male and female).

X

Y

6.1 Hydraulic

On the device side, a quick-disconnect coupling sleeve is provided on the piston rod side of

the valve, and a quick-disconnect coupling nipple on the cylinder base side of the valve; they

are connected to the pump unit via two extension hoses.

All LUKAS pairs of extension hoses are colour coded and are equipped with quick-disconnect

couplings so that they cannot be mixed up when being connected.

6. Connecting the equipment

WARNING / CAUTION / ATTENTION!

Prior to connecting the devices, ensure that

all the components

being used are suitable for the maximum operating pressure

of the pump unit. In the case of doubt you must consult LUKAS

directly!