12 problems / trouble shooting – Lukas Telescopic Rams User Manual

Page 10

10

11.2

Hydraulic system leakage

-

Check devices for oil loss and replace defective seals if necessary.

Important:

Carry out the following procedures over an oilpan; dispose of used oil!

11.3

Cylinder components

To remove the oil remaining in the piston main zone and piston ring zone, unscrew both couplings

from the connecting blocks if necessary and wait until all of the oil drains.

Then flush and fill up fresh hydraulic oil. Screw couplings in and tighten them to 45 Nm torque. Vent

cylinders acc. to chapter 6!

Remark:

Please note that the oil filling must be completely flushed and replaced by another type of oil if there

is a significant change in the operating conditions (ambient temperatures). Also refer to the

following chapter.

11.4

Oil recommendation

Oil for LUKAS hydraulic devices: Mineral oil in accordance with DIN 51524 and others

recommended viscosity range: 10 ... 200 (mm

2

/s).

12 Problems / Trouble shooting

Index: P = Problem;

S = Symptom;

F: Cylinder pistons cannot be retracted

S: red hose on the piston side is pressurized

—> quick-stop has been activated;

switch selector vlave to "lifting" for a moment and carefully start lowering again.

P: Hose couplings cannot be connected

S: red hose on the piston side is pressurized

—> hoses are under pressure since they have accidentally been disconnected without being

depressurized

- open union nut on hose, cover against oil spray,

- Hose is depressurized; pay attention to squirting oil,

- tighten union nut again (M

A

= 45 Nm).

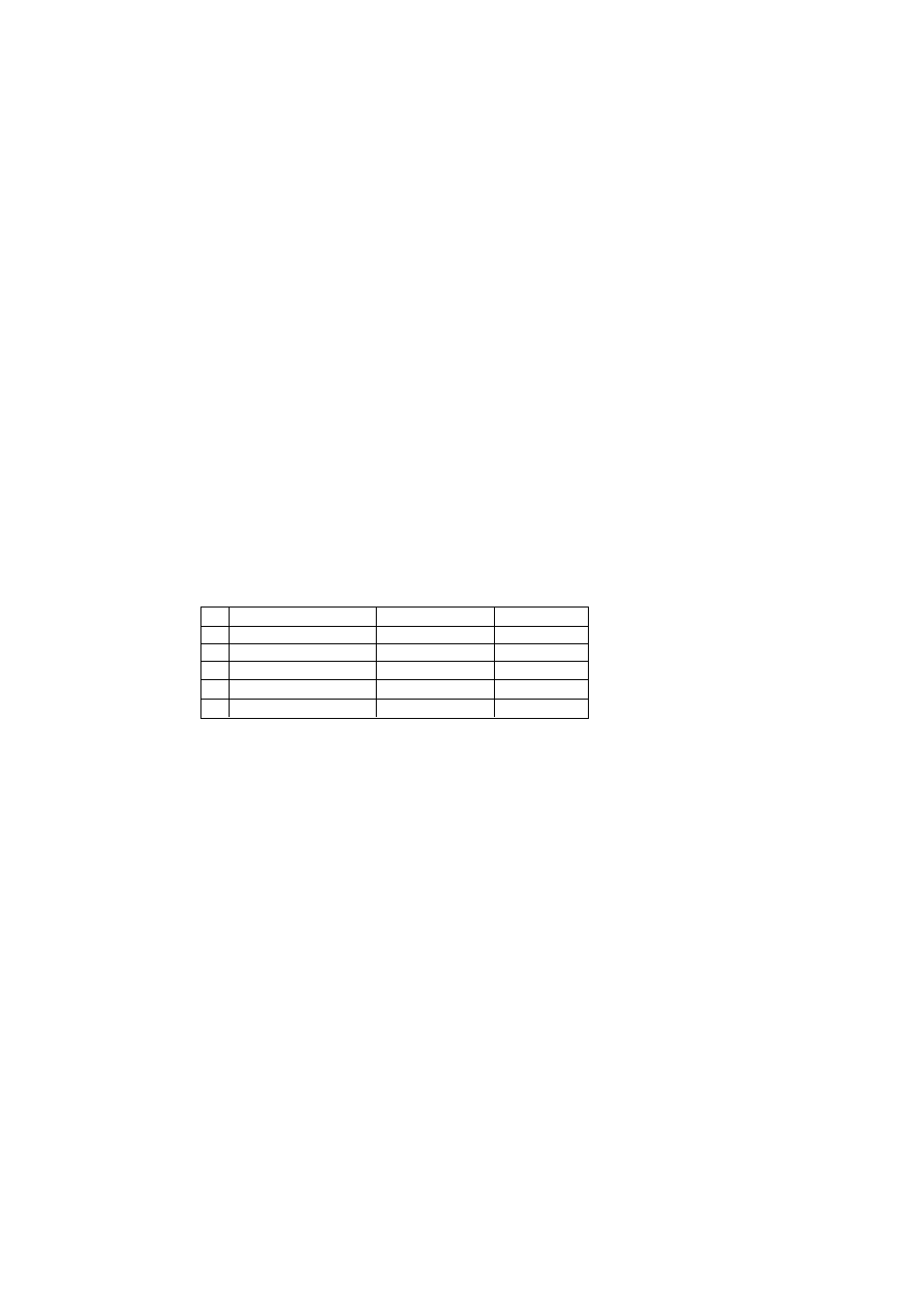

Range of oil temperature

Viscosity rating

Remarks

A

- 24 ... + 30 °C

HL 5

B

- 18 ... + 50 °C

HLP 10

C

- 8 ... + 75 °C

HLP 22

D

+ 5 ... + 80 °C

HLP 32

E

- 8 ... + 70 °C

HF - E 15

biodegradable