Lukas LSI 55 User Manual

Page 17

17

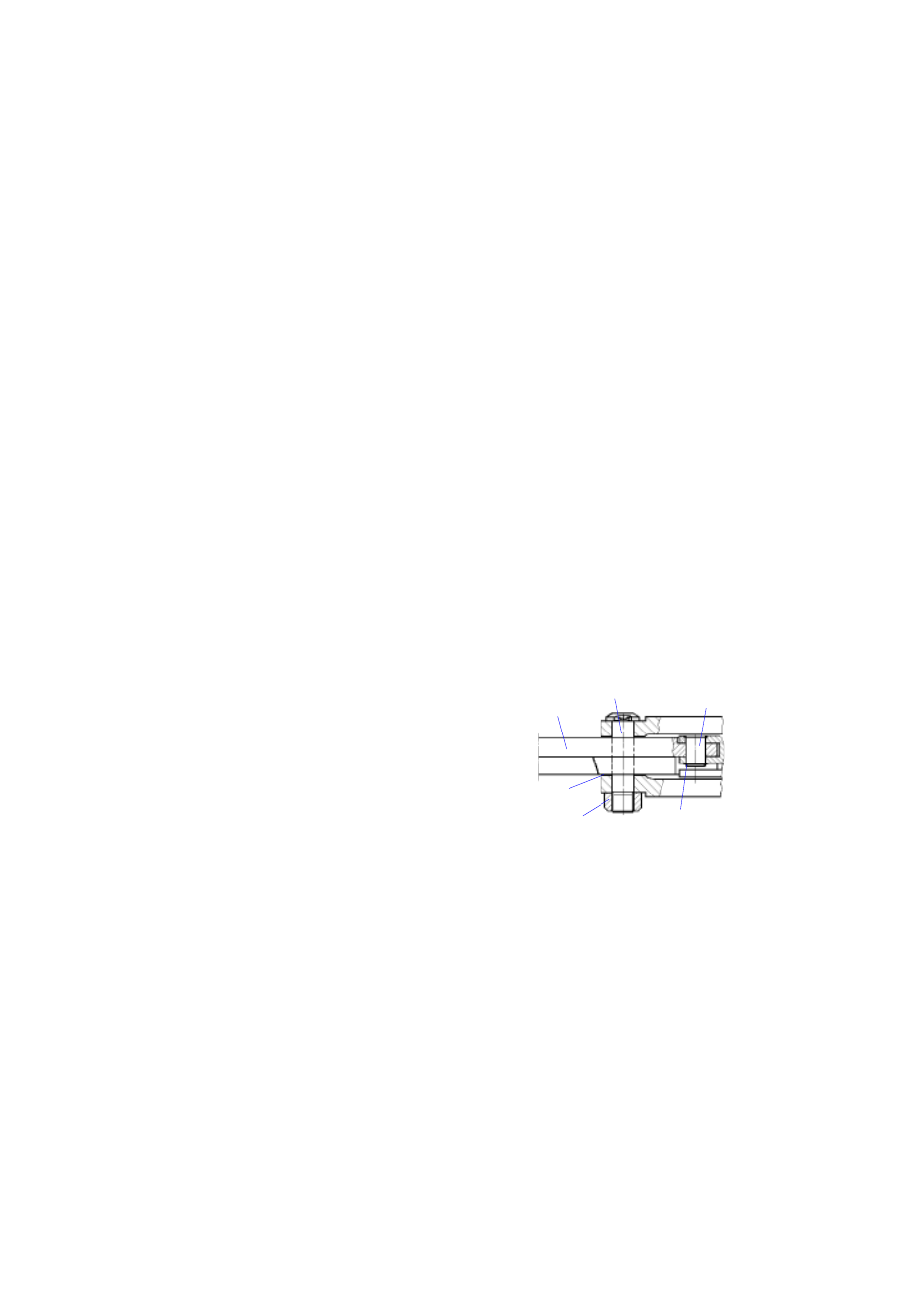

bolt

central bolt

blade arm

retaining ring

sliding plate

self-locking nut

12.2.3 Function and load test

If there are doubts about the safety and reliability, an additional function and load

test must be carried out. For that purpose LUKAS offers a test equipment.

12.2.4 Changing the hydraulic oil

- Change the hydraulic oil after approx. 500 operating hours, but after 2 yeas at latest;

- Whenever the oil of the appropriated pump (motor / hand pump) is changed. Mixing

the cutters used oil with fresh oil must be avoided because of impurity.

Procedure

The cutter is in closed (retracted) position • Change oil of the pump. Unscrew return hose

on the pump:

- for hose connection: unscrew the connector from the blue return line;

- for quick couplings: Fully release the union nut on the plug-in coupling of the blue

return line.

Slowly extend the device with the pump. Collect the old oil from the annulus side in a

separate container and dispose it like the old oil from the pump • Actuate the pump no

longer.

Reconnect the return hose to the pump:

- Tighten the union nut on the plug-in coupling according to 12.3.6,

- Tighten hose nipple in the valve block with M

A

= 45 Nm,

- Ventilate device according to 8.1

12.3 Repairs

12.3.1 Blades / blade arm and levers

Blades / blade arm and levers must be replaced if there are breakages and cracks or

if the blades are no longer in order as a result of multiple regrinding of the cutting edges

(12.2.1).

- Unscrew the nut from the central bolt

(wrench size of the jaw wrench see chapter

"Technical data") and remove the central bolt,

- Remove the retaining ring with retaining ring

nipper,

- Replace the blades and sliding plates,

- Insert bolts with retaining rings,

- Tighten the nut on the central bolt with torque

according to chapter „Technical data“.

Note: The bolts are accessible, when the blades are closed.

Attention:

Thoroughly clean all sliding surfaces before assembly and grease with LUKAS special

grease.