Maintenance, Maintenance schedule, Fluid levels – MBW R442 User Manual

Page 8: Engine maintenance, Engine speed, Checking percussion system oil, Aintenance

- 5 -

M

AINTENANCE

WARNING

Always exercise the stopping procedure before

servicing or lubricating the unit.

After servicing the unit, replace and fasten all

guards, shields, and covers to their original

positions before resuming operation.

CAUTION

Always verify fluid levels and check for leaks after

changing fluids.

Do not drain oil onto ground, into open streams,

or down sewage drains.

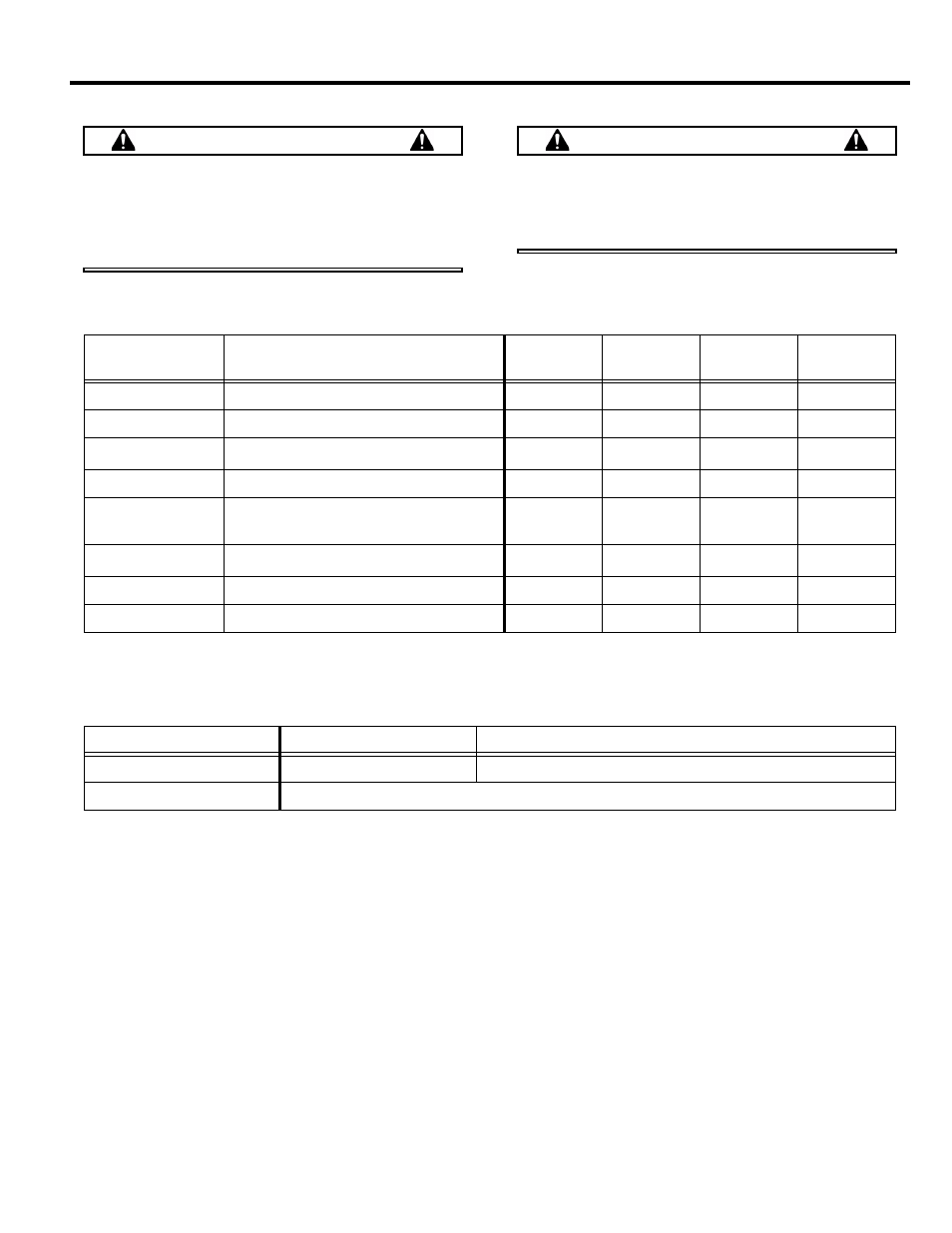

Maintenance Schedule

1.

Check all hardware after the first 5 hours of use, then follow the maintenance schedule.

2.

Change oil in lower unit after the first 50 hours of operation, then follow the maintenance schedule.

Fluid Levels

Engine Maintenance

Refer to the engine owner’s manual for maintenance

intervals and procedures.

• Check and clean the air cleaner element at least once

daily, The air cleaner has a foam pre-cleaner that can be

washed.

• Check the engine oil level by removing the dipstick (the

engine must be level). The oil level should be between

the marks on the dipstick. See the “Check Engine Oil”

section of the engine “Owner’s Manual” for information.

• See the “Change Engine Oil” section of the engine

“Owner’s Manual” for information on the oil change

intervals.

Engine Speed

Engine speed is factory set according to the speed listed in

the Specifications section of this manual. Refer to the

engine owners manual for procedure on setting operating

speed if necessary.

Checking Percussion System Oil

Refer to Lower Unit Assembly, page 16.

The rammer percussion system and gearbox are lubricated

by an oil mist which is formed and carried throughout the

rammer by a pumping action in the machine's lower system.

1.

Before daily operation, place the rammer on a flat

surface and check the oil level in the glass sight (#9)

on the spring box guard (#8).

SYSTEM

MAINTENANCE

DAILY

EVERY 25

HOURS

EVERY 300

HOURS

YEARLY

Air Cleaner

Check and clean

X

Engine

Refer to engine operator/owner manual

X

Hardware

Check and tighten as needed

1

X

X

In Line Fuel Filter

Replace

X

X

Percussion

System

Check oil level

X

Change oil

2

X

X

Shockmounts

Check for cracks or deterioration

X

Spark Plug

Replace

X

X

SYSTEM

FLUID VOLUME

RECOMMENDED OIL

Percussion System

18 oz

SF SAE 10W-30 Motor Oil

Engine

Refer to engine operator/owner manual