Bryant R-22 561G User Manual

Page 4

Use furnace transformer, fan-coil transformer, or accessory trans-

former for control power, 24v/40va minimum.

NOTE: Use of available 24v accessories may exceed the mini-

mum 40va power requirement. Determine total transformer load-

ing and increase the transformer capacity or split the load with an

accessory transformer as required.

IX.

COMPRESSOR CRANKCASE HEATER

1. When equipped with a crankcase heater, energize heater a

minimum of 24 hr before starting unit. To energize heater

only, set thermostat to OFF mode and close electrical

disconnect to outdoor unit.

A crankcase heater is required if refrigerant tubing is longer than

80 ft.

X.

INSTALL ELECTRICAL ACCESSORIES

Refer to individual instructions packaged with kits or accessories

when installing.

XI.

START-UP

CAUTION: PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal

injury.

Service valve gage ports are equipped with Schrader

valves. Wear safety glasses and gloves when handling

refrigerant.

1. Fully open liquid and vapor service valves.

2. Unit is shipped with valve stem(s) front seated (closed) and

caps installed. Replace stem caps after system is opened to

refrigerant flow. Replace caps finger-tight and tighten an

additional 1/12 turn with wrench.

3. Close electrical disconnects to energize system.

4. Set room thermostat at desired temperature. Be sure set

point is below indoor ambient temperature.

5. Set room thermostat to COOL and fan control to ON or

AUTO mode. Operate unit for 15 minutes. Check system-

refrigerant charge. (See Check Charge.)

WARNING: PERSONAL INJURY AND ENVIRNO-

MENTAL HAZARD

Failure to follow this warning could result in personal

injury or death. Relieve pressure and recover all refrig-

erant before system repair or final unit disposal. Use all

service ports and open all flow control devices, including

solenoid valves.

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit compo-

nent damage.

•

3-phase scroll compressors are rotation sensitive.

•

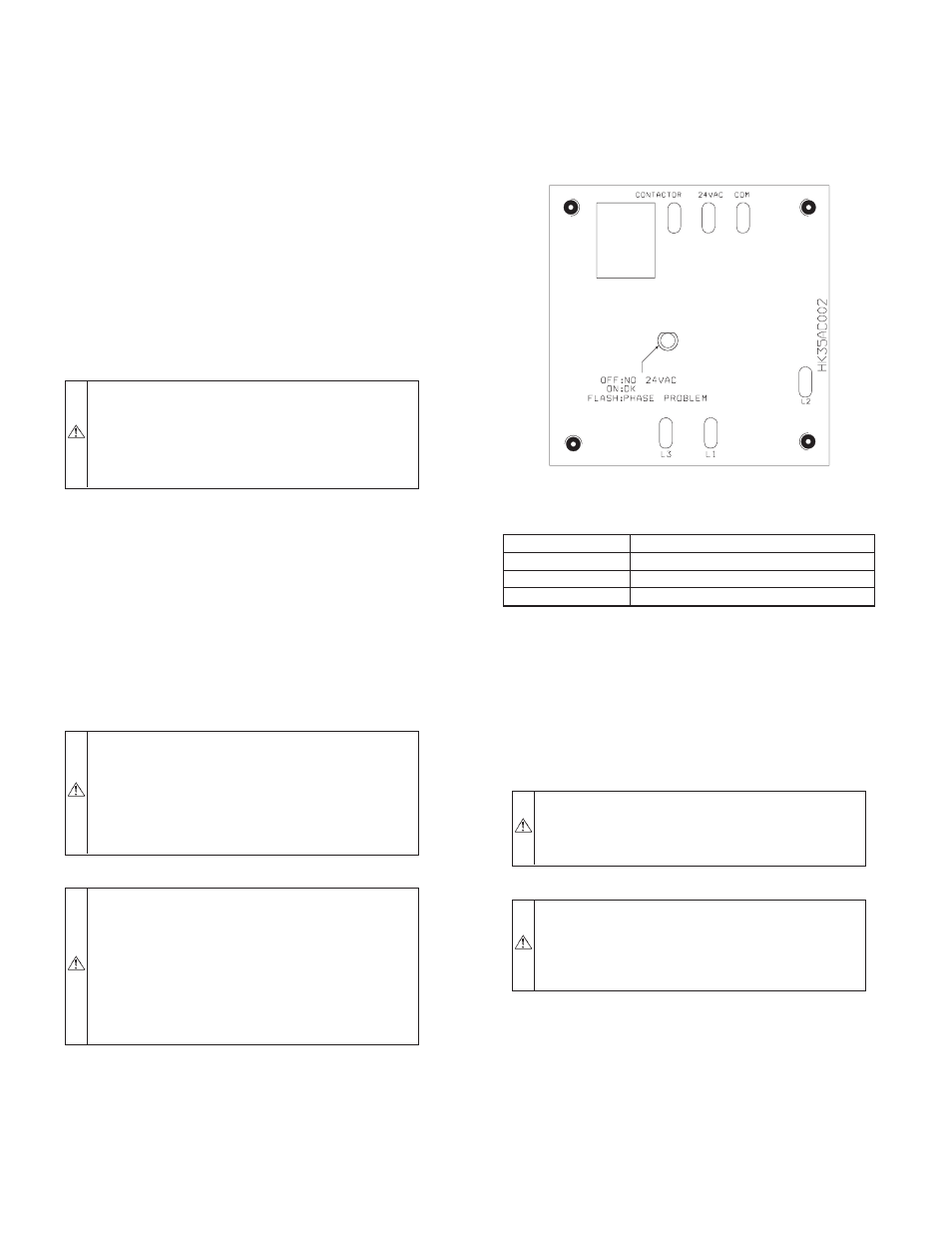

A flashing LED on phase monitor indicates reverse

rotation. (See Fig. 5 and Table 2.)

•

This will not allow contactor to be energized.

•

Disconnect power to unit and interchange 2 field

wiring leads on unit contactor.

A.

SEQUENCE OF OPERATION

Turn on power to indoor and outdoor units. Transformer is

energized.

On a call for cooling, thermostat makes circuits R-Y and R-G.

Three phase models with scroll compressors, are equipped with a

phase monitor to detect if the incoming power is correctly phased

for compressor operation. (See Fig. 5 and Table 2.) If the phasing

is correct, circuit R-Y energizes contactor, starting outdoor fan

motor and compressor circuit. R-G energizes indoor unit blower

relay, starting indoor blower motor on high speed.

NOTE: If the phasing is incorrect, the contactor will not be

energized. To correct the phasing, interchange any two of the three

power connections on the field side.

When thermostat is satisfied, its contacts open, de-energizing

contactor and blower relay. Compressor and motors stop.

If indoor unit is equipped with an off delay circuit, the indoor

blower can run an additional 120 sec to increase system efficiency.

XII.

CHECK CHARGE

UNIT CHARGE

Factory charge is shown on unit rating plate. Charge procedure is

shown on wiring/charging label locate on unit.

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit compo-

nent damage. Compressor damage may occur if system is

overcharged.

CAUTION: ENVIRNOMENTAL HAZARD

Failure to follow this caution may result in environmental

damage and fines. Federal regulations require that you do

not vent refrigerant to the atmosphere. Recover during

system repair or final unit disposal.

A.

Cooling Only Procedure—Indoor unit equipped with

piston, superheat method

Factory charge is shown on unit rating plate. To check charge in

cooling mode, refer to Cooling Only Procedure on unit wiring and

charging label.

NOTE: If superheat or subcooling charging conditions are not

favorable, charge must be weighed in accordance with unit rating

plate ± 0.6 oz/ft of 3/8-in. liquid line above or below 15 ft

respectively.

Fig. 5—3-Phase Monitor Control

A00010

TABLE 2—PHASE MONITOR LED INDICATORS

LED

STATUS

OFF

No call for compressor operation

FLASHING

Reversed phase

ON

Normal

—4—